Hydrophilic bactericidal anti-contamination reverse osmosis membrane and preparation method thereof

A reverse osmosis membrane, anti-pollution technology, applied in the field of water treatment, to achieve the effect of inhibiting growth, convenient operation and improving anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

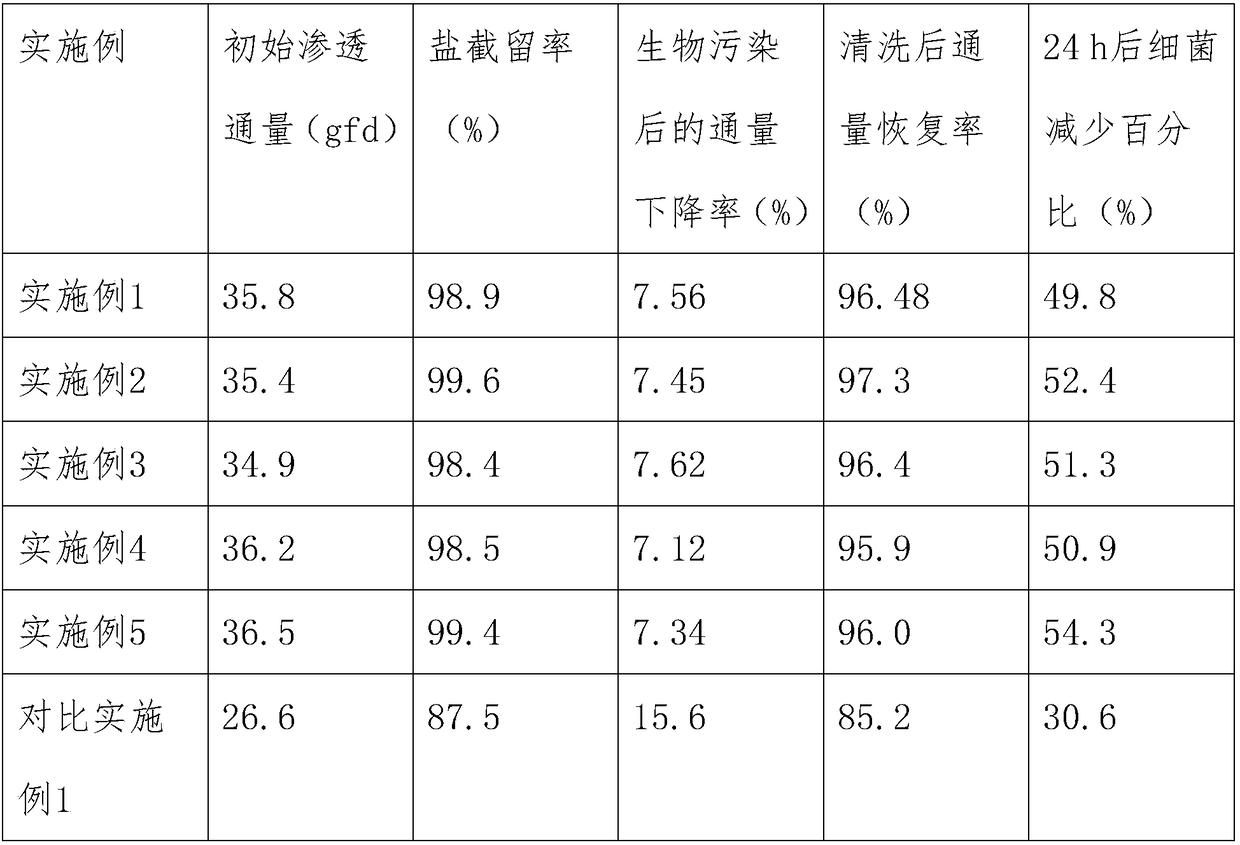

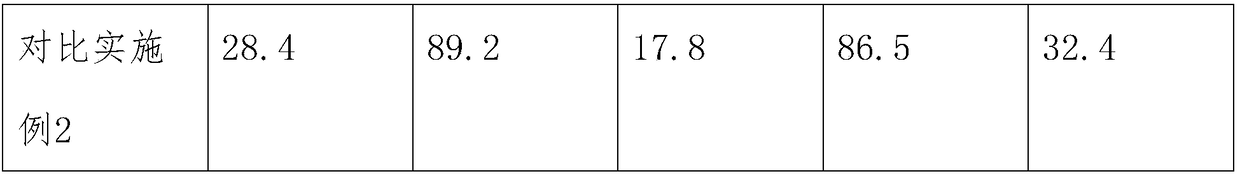

Examples

Embodiment 1

[0028] (1) Fix the aromatic polyamide composite reverse osmosis membrane produced by our company (ULP11, the flux is 35.2gfd, the desalination rate is 99.4%, the size is 15×13 cm) between two plexiglass frames and a rectangular hollow silica gel pad In between, the size of the rectangular hollow silica gel pad is the same as that of the plexiglass frame, immersed in 25% isopropanol solution for 30min, rinsed with pure ethanol solvent, and placed in N 2 Tumble dry under cover.

[0029] (2) Prepare 40 mL of acetonitrile solution, add 2-(ethyltrithiocarbonate)-2-methylpropionic acid ACPA (0.246 g, 1.1 mmol), dicyclohexylcarbodiimide DCC (0.454 g, 2.2mmol), the reverse osmosis membrane was placed in the acetonitrile solution and reacted for 24h. The membrane was washed repeatedly with acetonitrile to obtain the polyamide reverse osmosis membrane ACPA-TFC with RAFT chain transfer agent.

[0030](3) At room temperature, add methacryloyl ethyl sulfobetaine SBMA (8.37g, 30mmol) and ...

Embodiment 2

[0036] (1) Soak the reverse osmosis membrane in 25% isopropanol solution for 30 minutes, take it out, rinse it with pure ethanol solvent, and dry it;

[0037] (2) Graft RAFT chain transfer reagent on the reverse osmosis membrane: add 2-(ethyltrithiocarbonate)-2-methylpropionic acid (ACPA) and dicyclohexylcarbodiimide (DCC) to acetonitrile In the solvent, shake well and mix, put the reverse osmosis membrane into the above solution, react for 24h, take it out, rinse the membrane 5 times with pure acetonitrile solvent, and obtain the polyamide membrane (ACPA-TFC) with RAFT chain transfer agent; , wherein the molar ratio of ACPA to DCC is 1:2;

[0038] (3) RAFT reaction of SBMA: at room temperature, add monomer 1 and photoinitiator into acetonitrile solvent, stir until completely dissolved, pass nitrogen gas to remove oxygen for 6 minutes, put the diaphragm into the above acetonitrile solution, and react under LED light 6h; after the reaction, the diaphragm was cleaned with aceto...

Embodiment 3

[0042] (1) Soak the reverse osmosis membrane in 25% isopropanol solution for 24 minutes, take it out, rinse it with pure ethanol solvent, and dry it;

[0043] (2) Graft RAFT chain transfer reagent on the reverse osmosis membrane: add 2-(ethyltrithiocarbonate)-2-methylpropionic acid (ACPA) and dicyclohexylcarbodiimide (DCC) to acetonitrile In the solvent, shake and mix, put the reverse osmosis membrane into the above solution, react for 18h, take it out, rinse the membrane 4 times with pure acetonitrile solvent, and obtain the polyamide membrane (ACPA-TFC) with RAFT chain transfer agent; , wherein the molar ratio of ACPA to DCC is 1:2;

[0044] (3) RAFT reaction of SBMA: At room temperature, add monomer 1 and photoinitiator into acetonitrile solvent, stir until completely dissolved, pass nitrogen gas to remove oxygen for 5 minutes, put the diaphragm into the above acetonitrile solution, and react under LED light 4h; after the reaction, the diaphragm was cleaned with acetonitri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com