Core-shell structured supported carbon nanotube catalyst and preparation method thereof

A technology of carbon nanotubes and core-shell structure, which is applied in the field of core-shell structure-loaded carbon nanotube catalysts and their preparation, can solve the problems of high cost and complicated process, and achieve the effects of low equipment requirements, simple raw materials, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

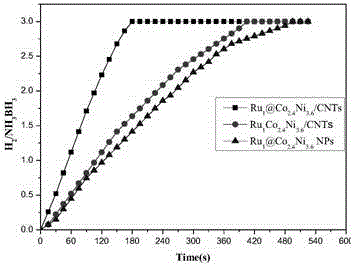

[0028] Example 1: Preparation of core-shell structure Ru@CoNi / CNTs supported carbon nanotube catalyst

[0029] Weigh a certain amount of commercial carbon nanotubes (40-60nm) and add mixed acid (H 2 SO 4 :HNO 3 =3:1) solution, condensed and refluxed at 120° C. for 2 hours; cooled the solution, adjusted the pH to neutral with alkali, filtered, washed, and dried to obtain activated carbon nanotubes.

[0030] Weigh 8 mg of the above-mentioned carbon nanotubes, in a solution (40 mL) with a volume ratio of 1:1 of ethylene glycol and water, sonicate for 10 minutes, and then add RuCl 3 (0.24mL, 0.01mol / L), Co(NO 3 ) 2 (0.576mL, 0.01mol / L), Ni(NO 3 ) 2 (0.864mL, 0.01mol / L) solution, stirred for 24 hours. Dissolve 60.0 mg of ammonia borane solid (reducing agent) in 10 mL of deionized water, add this solution dropwise to the above solution, and continue stirring for 10 minutes until no bubbles are generated. The product was filtered, washed, and dried to obtain a core-shell stru...

Embodiment 2

[0032] Example 2 (Comparison 1): Preparation of Alloy Structure RuCoNi / CNTs Supported Catalyst

[0033] Weigh a certain amount of commercial carbon nanotubes (40-60nm) and add mixed acid (H 2 SO 4 :HNO 3 =3:1) solution, condensed and refluxed at 120° C. for 2 hours; cooled the solution, adjusted the pH to neutral with alkali, filtered, washed, and dried to obtain activated carbon nanotubes.

[0034] Weigh 8 mg of the above-mentioned carbon nanotubes, in a solution (40 mL) with a volume ratio of 1:1 of ethylene glycol and water, sonicate for 10 minutes, and then add RuCl 3 (0.24mL, 0.01mol / L), Co(NO 3 ) 2 (0.576mL, 0.01mol / L), Ni(NO 3 ) 2 (0.864mL, 0.01mol / L) solution, stirred for 24 hours. Dissolve 60.0 mg of sodium borohydride solid (reducing agent) in 10 mL of deionized water, add this solution dropwise to the above solution, and continue stirring for 10 minutes until no bubbles are generated. The product is filtered, washed and dried to obtain an alloy structure RuC...

Embodiment 3

[0035] Example 3 (Comparison 2): Preparation of Ru@CoNi nanoparticles with core-shell structure

[0036] Add RuCl 3 (0.24mL, 0.01mol / L), Co(NO 3 ) 2 (0.576mL, 0.01mol / L), Ni(NO 3 ) 2 (0.864mL, 0.01mol / L) solution was mixed and stirred for 24 hours. Dissolve 60.0 mg of ammonia borane solid (reducing agent) in 10 mL of deionized water, add this solution dropwise to the above solution, and continue stirring for 10 minutes until no bubbles are generated. The product was filtered, washed and dried to obtain the Ru@CoNi nanoparticle catalyst with core-shell structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com