Scr catalyst for removal of nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The present invention will be further illustrated by the following examples in order to provide a better understanding of the invention. However, the present invention is not limited to the examples, and particularly, the substances that compose each layer can be other substances that are within the technical effect of the present invention.

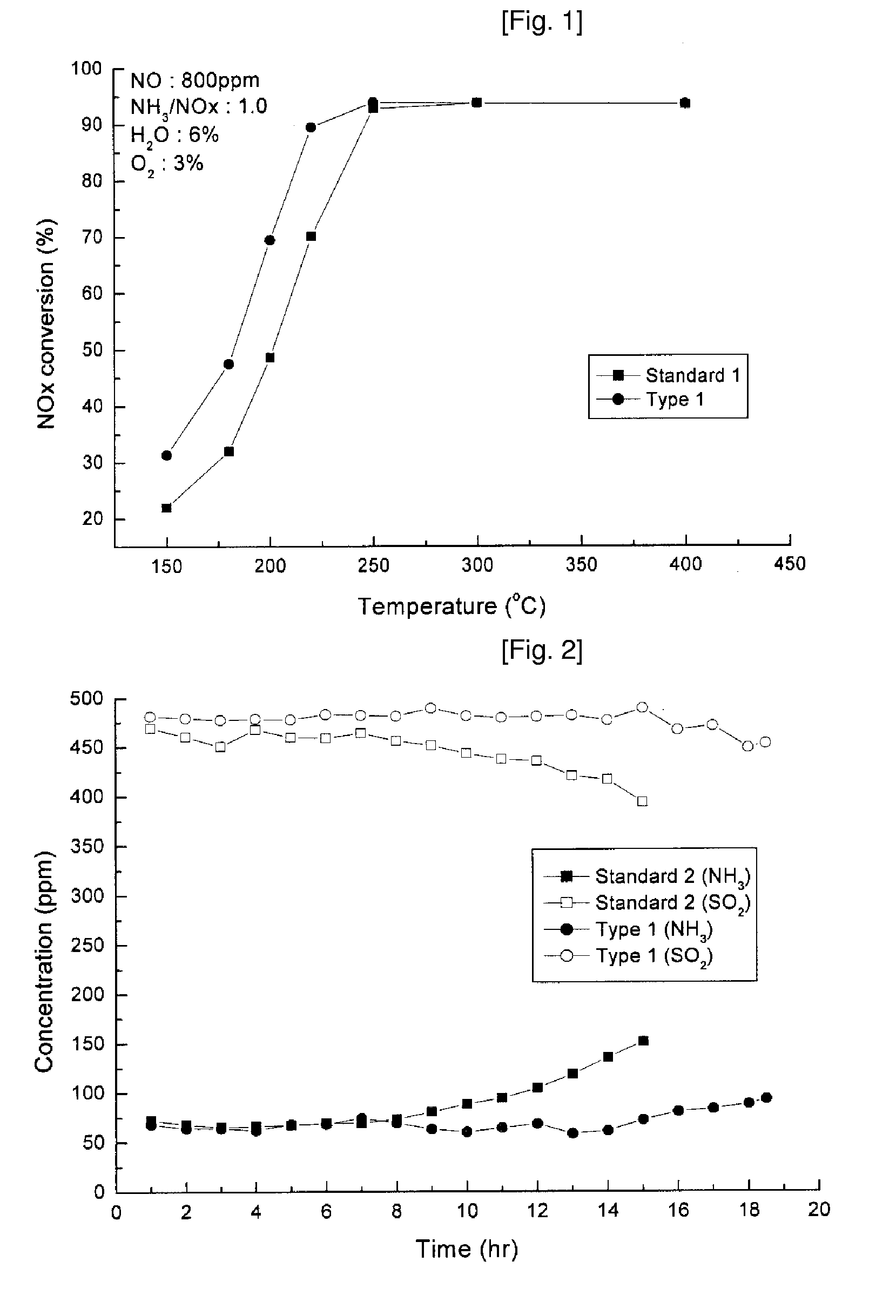

[0027]FIG. 1 shows NO conversion without the presence of antimony according to Reference 1 (standard 1) and one with antimony at different temperatures according to Example 1 (type 1) of the present invention.

[0028]Reference 1 uses titanium oxide (TiO2) carrier, without antimony added and impregnated with 2 wt. % of vanadium as an active material. Example 1 uses titanium oxide (TiO2) carrier which is impregnated with 2 wt. % of vanadium as an active material and 2 wt. % of antimony oxide as a minor catalyst. The amounts of nitrogen oxides and ammonia used are each 800 ppm, the amount of water is 6%, and the amount of oxygen is 3%.

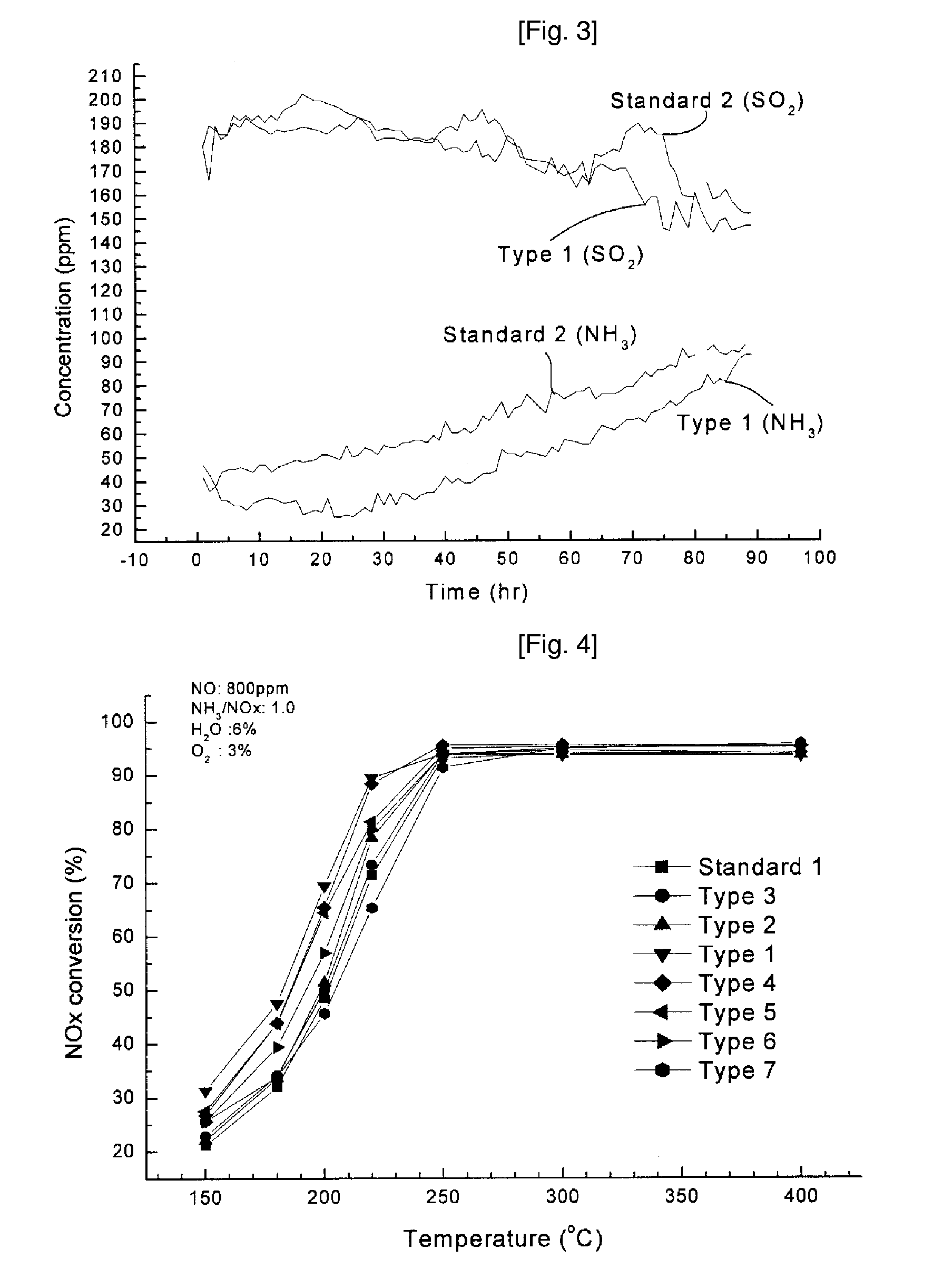

[0029]FIG....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

| Catalytic activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com