Technology of microwave vacuum extrusion of lonicera edulis chip

A microwave vacuum puffing and microwave vacuum technology, which is applied in the field of food processing, can solve the problems of unsatisfactory comprehensive quality of puffing rate, hardness, brittleness, color, high processing cost, and large consumption of cooking oil, etc., and achieve bright color and short drying and heating time. Long-term, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

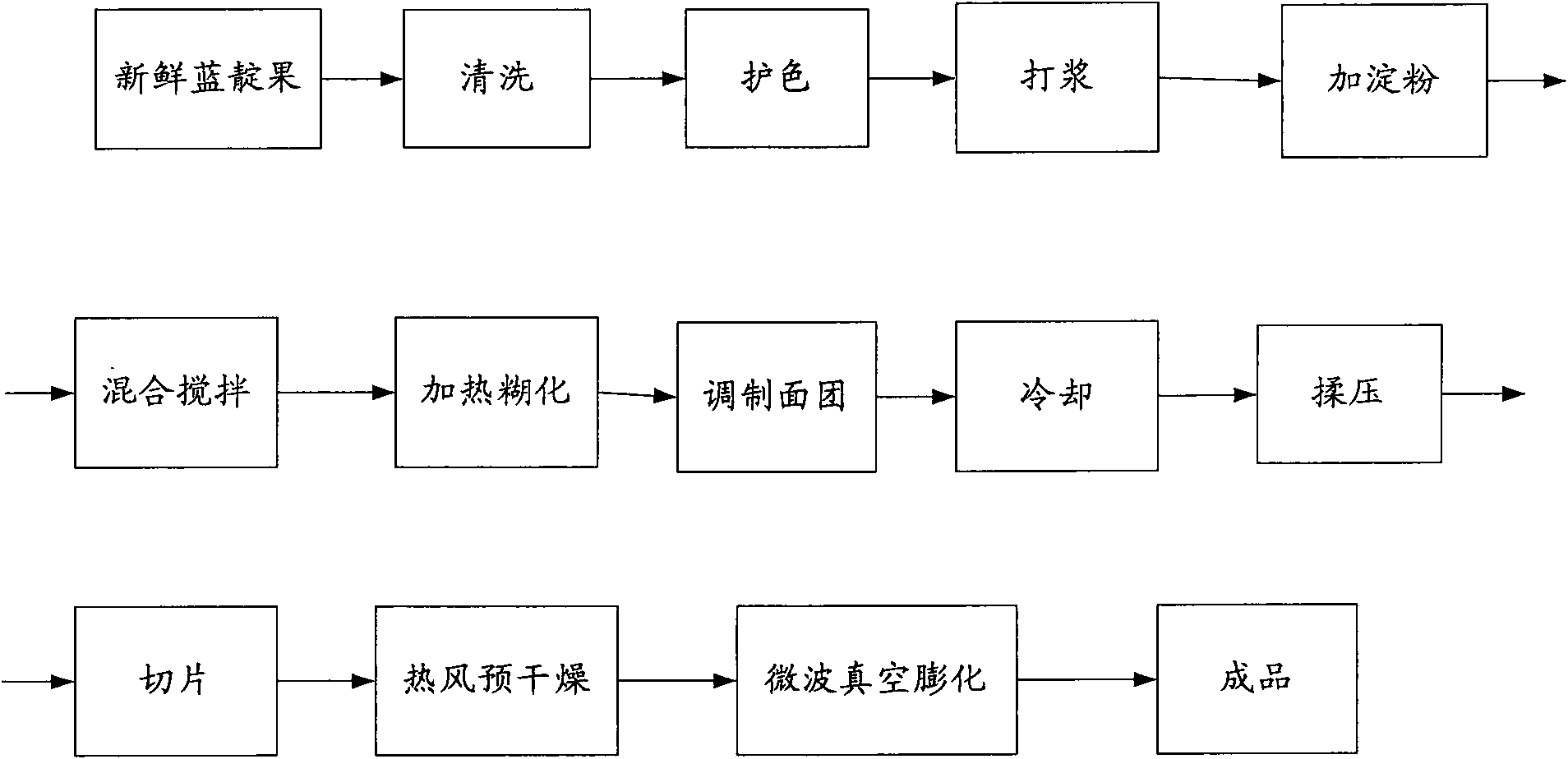

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 microwave vacuum puffing

[0028] 1. Raw material pretreatment of indigo slices

[0029] Clean the fresh indigo fruit with clean water to remove surface impurities, silt, etc.; soak in the color protection solution (0.1% citric acid solution by mass ratio), protect the color for 15 minutes, rinse with water repeatedly, and then drain the surface water. Place in a refiner and grind into a fine slurry, weigh 250g fruit pulp, add therein the starch that accounts for 30% of the pulp quality, wherein the starch is potato starch, glutinous rice flour and cornstarch with the quality of 2:1:1 Proportionally mixed, then stirred with a mixer for 15 minutes to ensure that the slurry was evenly mixed. Then put it in a constant temperature water bath at 70°C, heat and gelatinize for 2.5 hours, knead it into a ball, and put it in a refrigerator to cool and store.

[0030] Put the fruit mass in a slicer and knead it repeatedly, then extrude it into a 3mm long piece in a...

experiment example 1

[0050] Experimental example 1 sensory quality analysis

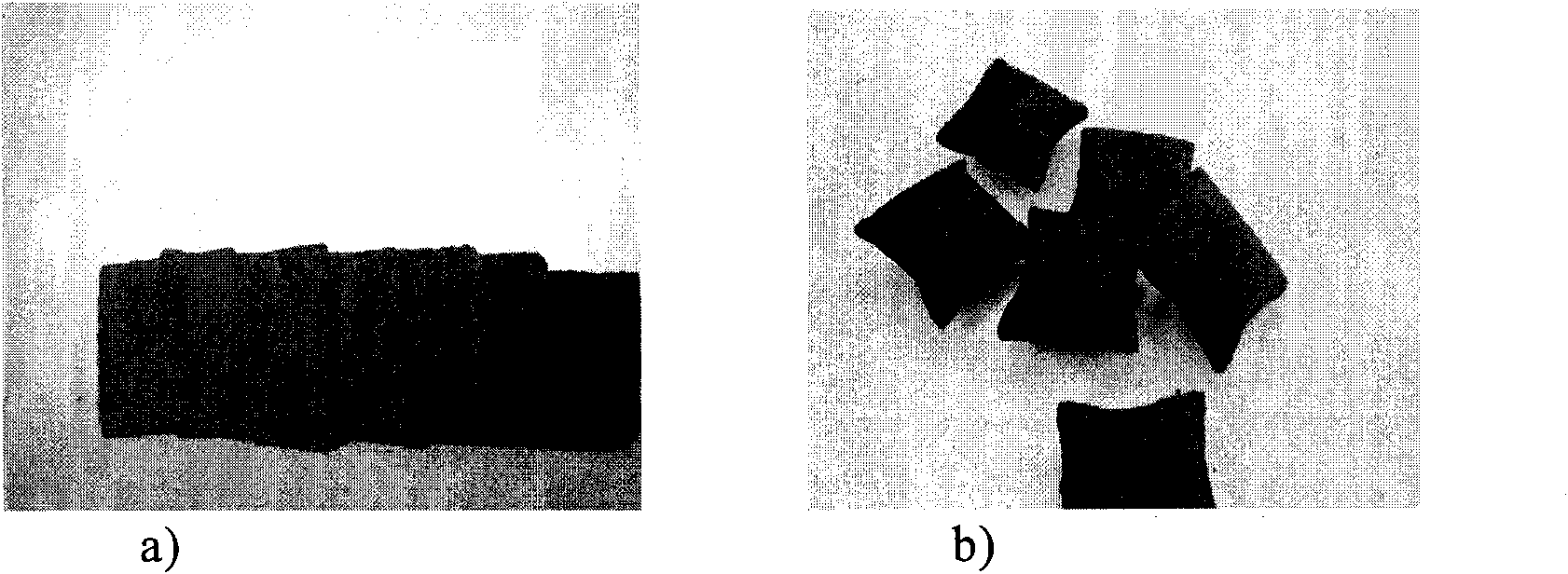

[0051] Comparison of sensory quality of indigo fruit slices prepared by different methods, see figure 2 shown.

[0052] In terms of appearance, there is a significant difference between the hot air drying and microwave vacuum puffing samples, and the color is better, both of which are rose red. The hot air-dried blue indigo slices had a flat surface, and the samples were evenly dried; the microwave vacuum puffed crispy slices were significantly larger in volume, hollow inside, and large bubbles appeared in the center, but a small amount of samples showed coking in the center;

[0053] In terms of texture, hot-air-dried indigo fruit slices have a uniform texture, no puffing effect, local crisps shrink to a certain extent, and the taste is relatively hard, while microwave vacuum puffed indigo fruit chips have good puffing effect, fluffy and crispy taste, and good chewing feeling;

[0054] In terms of flavor, because the...

experiment example 2

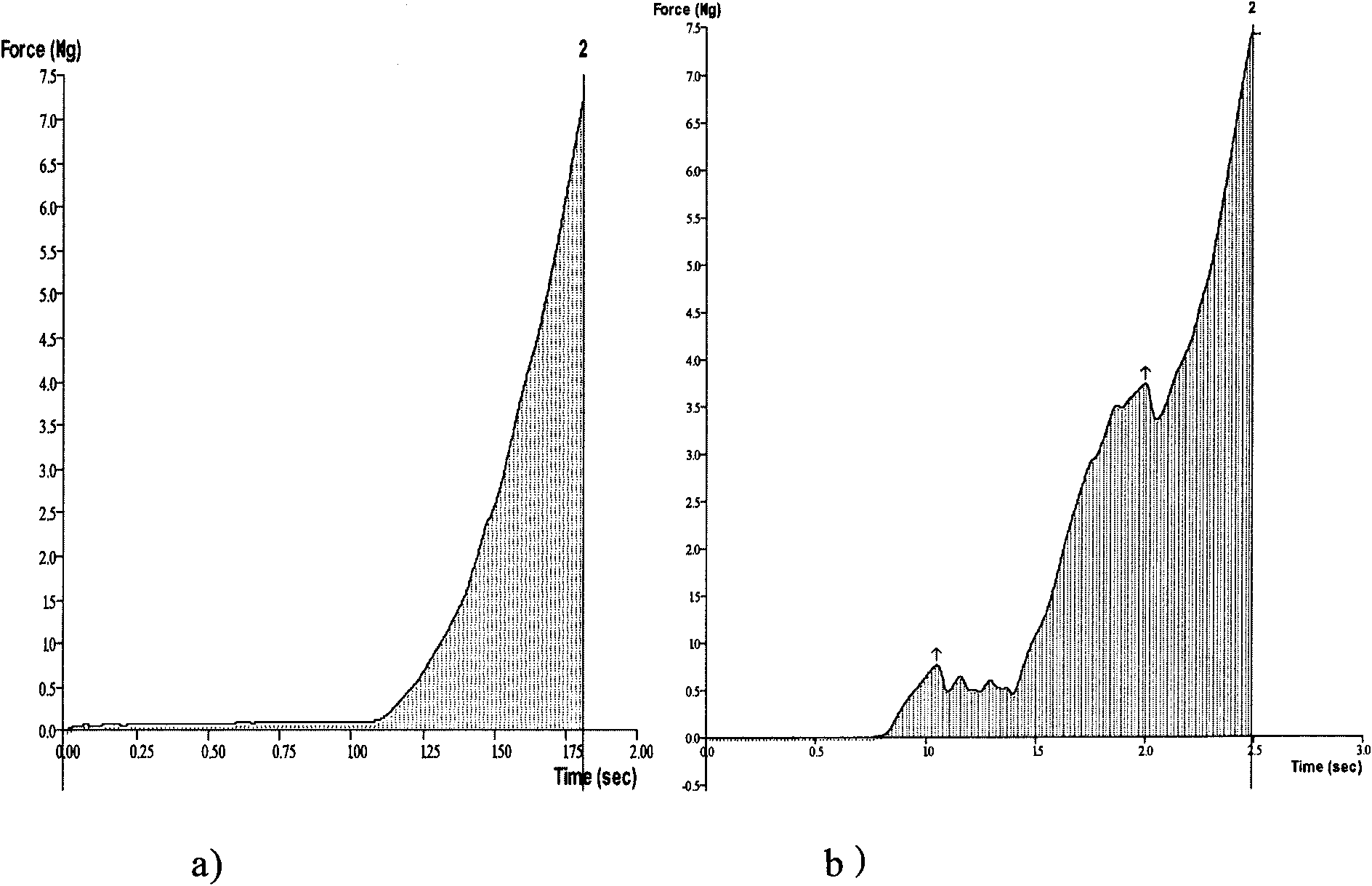

[0056] Experimental Example 2 Texture Determination

[0057] The test uses TA.XT-plus texture analyzer to measure its hardness and brittleness. Texture parameter setting: probe number: HDP / KS5; test mode: compression; test speed: 1mm / s; target mode: strain; force level: 50%. Obtain the hardness value and brittleness value (number of peaks) of the chips. Theoretically, the smaller the hardness of the chips and the more peaks (good brittleness), the better the quality. In the experiment, 6 pieces of indigo crisps were selected under different puffing and drying conditions, placed in two rows, with 3 pieces in each row, and the hardness value and peak number of the chips were measured. Each group was repeated twice, and the average value was taken.

[0058] As a leisure puffed food, blue indigo crisps, its texture parameters are an important index to evaluate its quality. The texture analyzer is also called the physical property tester, which can make a digital expression of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average temperature | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com