Micro unmanned aerial vehicle carbon fiber rotor wing and preparation method thereof

A carbon fiber, micro-miniature technology, applied in the field of micro-miniature UAV carbon fiber rotor and its preparation, can solve the problems of high mass, low output power, low lift, etc., and achieve the effects of low rotational speed, low power consumption, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

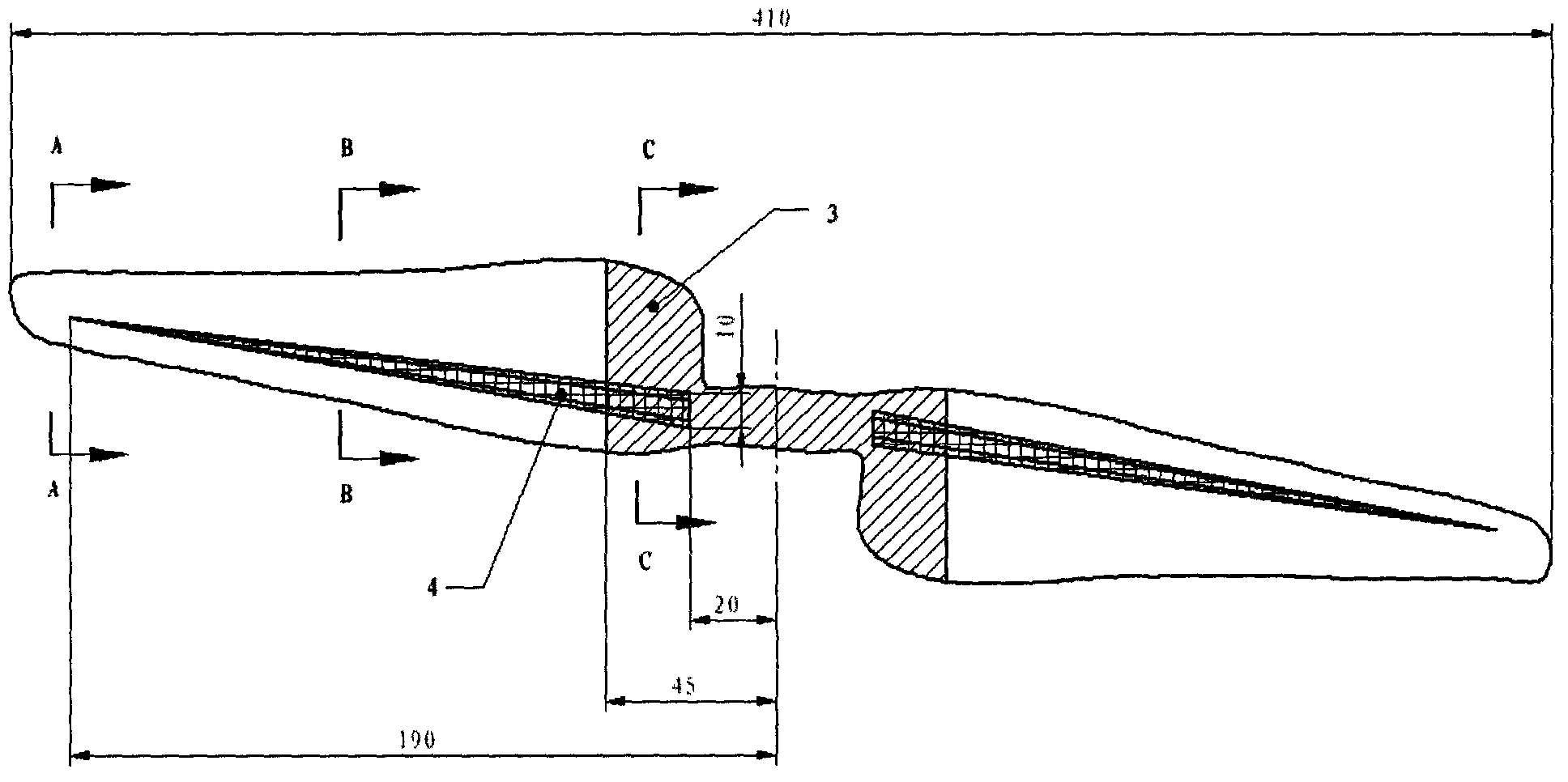

[0041] A carbon fiber rotor for micro-miniature drones, such as figure 1 As shown; the rotor from both ends to the middle is the wingtip, wing body and wing root in turn; the total length of the rotor is 410mm, counting from the center of the rotor as the origin, the left side of the origin is negative, and the right side of the origin The side is positive, from -45 to +45 is the wing root, from -190 to -45 and +45 to +190 is the wing body, and the rest is the wing tip;

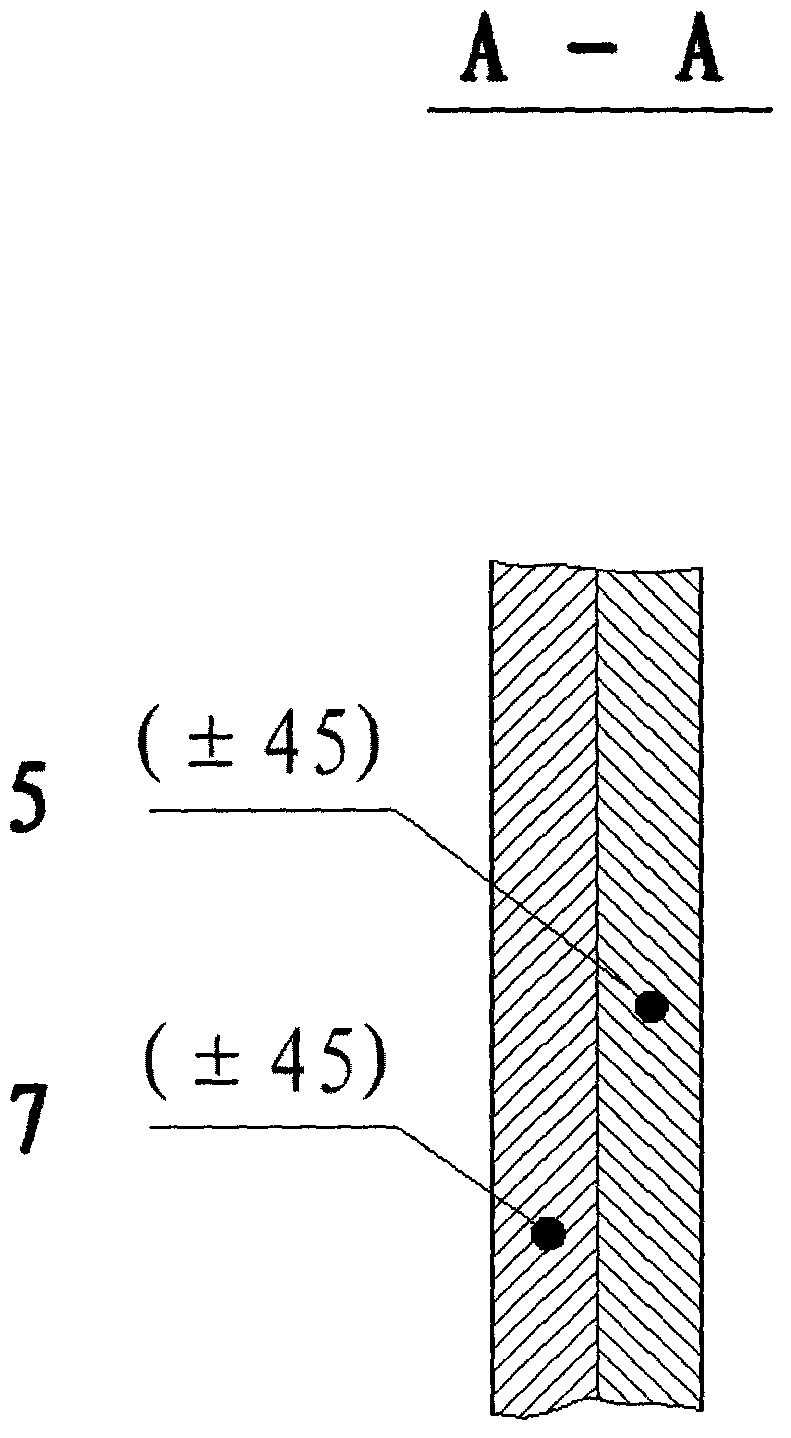

[0042] Wing tip is successively upper surface layer 5 and lower surface layer 7 from top to bottom; figure 2 shown;

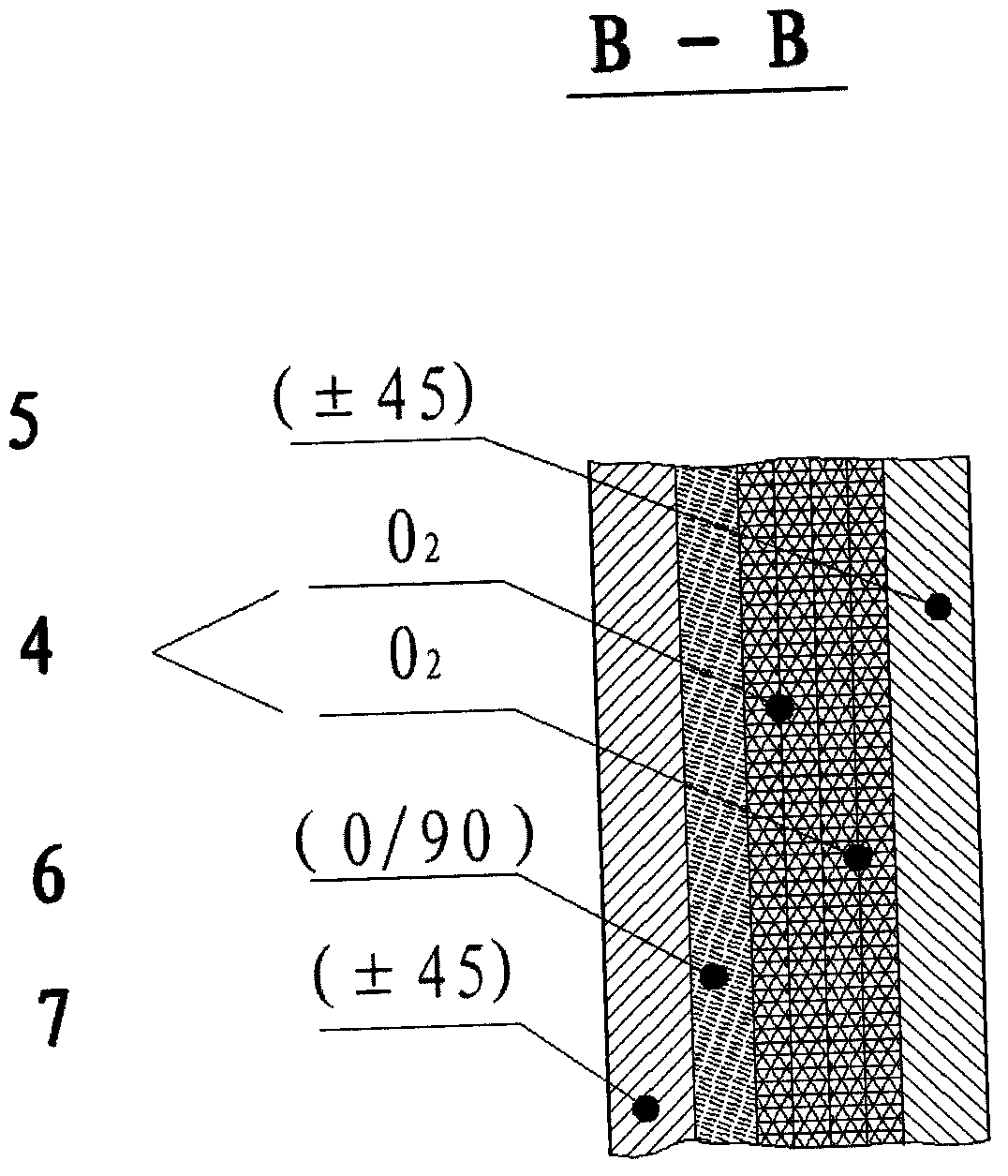

[0043] From top to bottom, the wing body is the upper surface layer 5, the ribs 4, the middle layer 6 and the lower surface layer 7; image 3 shown;

[0044] From top to bottom, the wing root is the upper surface layer 5, the rib 4, the reinforcement layer 3, the middle layer 6 and the lower surface layer 7; Figure 4 shown;

[0045] Above-mentioned upper surface layer 5 adopts 45 ° of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com