Biomass load type nano-metal catalyst and preparation method and application thereof

A nano-metal and supported technology is applied in the field of biomass-supported nano-metal catalyst and its preparation, which can solve the problems of low metal nano-particle catalyst loading, easy aggregation and instability of metal nano-particles, etc. The effect of strong capacity, easy recycling and high load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

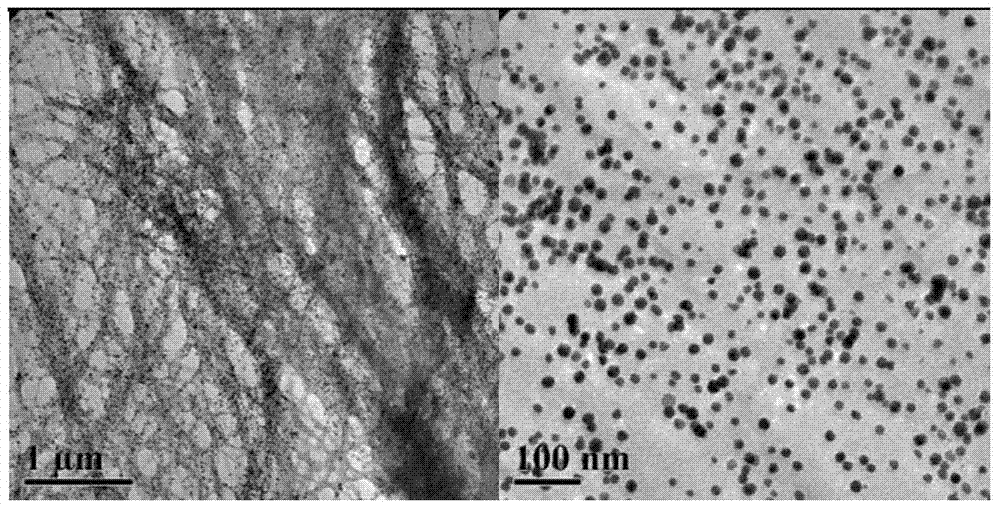

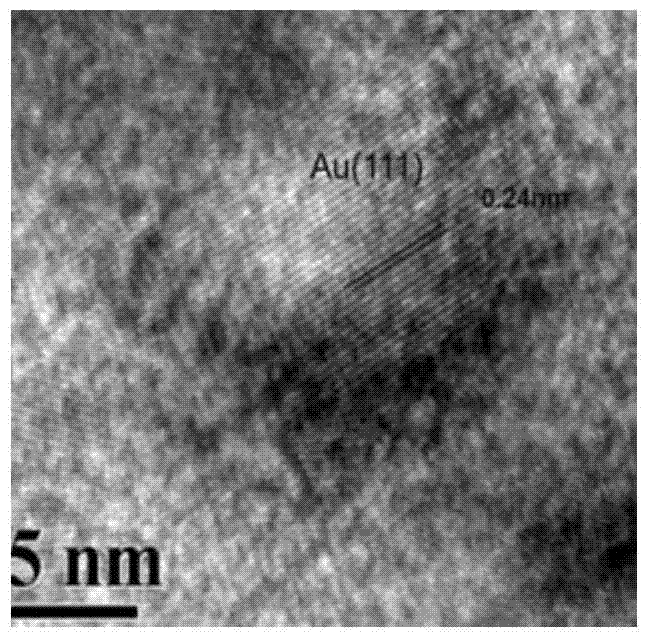

[0066] Embodiment 1: the preparation of the MNPsAOFC catalyst that the mass content of amidoxime group is 16.84%

[0067] Preparation of cyanoethyl bacterial cellulose:

[0068] Soak 40mL of nano bacterial cellulose (solid content is 0.9%, particle size is about 30nm, mass of bacterial cellulose is 0.36g) that has been ground with a grinding disc for 7h in 40mL of 1mol / L NaOH, then directly add 100mL In a round-bottomed flask, at room temperature with a stirring speed of 900rpm / min, 20mL of acrylonitrile monomer (16.12g) was added dropwise into the round-bottomed flask while stirring, and the reaction was completed after 12 hours of reaction, and the reaction in the round-bottomed flask was The final product was washed 3 times with ultrapure water, and the supernatant was removed by centrifugation to obtain 0.51 g of cyanoethyl bacterial cellulose.

[0069] Preparation of amidoxime functionalized bacterial cellulose:

[0070] Weigh 10g of hydroxylamine hydrochloride (NH 2 O...

Embodiment 2

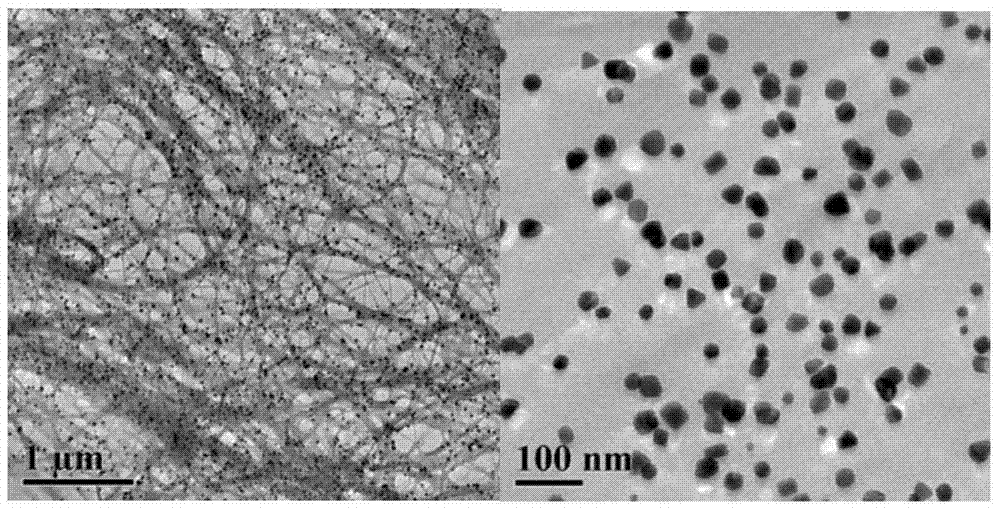

[0074] Embodiment 2: the preparation of the MNPsAOFC catalyst that the mass content of amidoxime group is 3.88%

[0075] Preparation of cyanoethyl bacterial cellulose:

[0076] Soak 40mL of nano-bacterial cellulose (solid content is 0.9%, particle size is about 30nm, mass of bacterial cellulose is 0.36g) that has been ground with a grinding disc in 40mL of 1mol / L NaOH for 0.5h, then directly add In a 100mL round-bottomed flask, 20mL of acrylonitrile monomer (16.12g) was added dropwise into the round-bottomed flask while stirring at a stirring rate of 900rpm / min at room temperature, and the reaction was completed after 12 hours of reaction. The reacted product was washed 3 times with ultrapure water, and the supernatant was removed by centrifugation to obtain 0.44 g of cyanoethyl bacterial cellulose.

[0077] Preparation of amidoxime-functionalized cellulose:

[0078] Weigh 10g of hydroxylamine hydrochloride (NH 2 OHxHCl) solid and 5.8g NaOH solid were added to a 100mL round...

Embodiment 3

[0082] Embodiment 3: the preparation of the MNPsAOFC catalyst that the mass content of amidoxime group is 13.64%

[0083] Preparation of cyanoethyl bacterial cellulose:

[0084] Soak 40mL of nano bacterial cellulose (solid content is 0.9%, particle size is about 30nm, mass of bacterial cellulose is 0.36g) that has been ground with a grinding disc for 7h in 40mL of 1mol / L NaOH, then directly add 100mL In a round-bottomed flask, at room temperature with a stirring speed of 900rpm / min, 20mL of acrylonitrile monomer (16.12g) was added dropwise into the round-bottomed flask while stirring, and the reaction was completed after 12 hours of reaction, and the reaction in the round-bottomed flask was The final product was washed 3 times with ultrapure water, and the supernatant was removed by centrifugation to obtain 0.47 g of cyanoethyl bacterial cellulose.

[0085] Preparation of amidoxime-functionalized cellulose:

[0086] Weigh 10g of hydroxylamine hydrochloride (NH 2 OHxHCl) solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com