Preparation method of three-dimensional mesoporous NiCo2O4/nitrogen-doped graphene composite electrode material

A technology of nitrogen-doped graphene and composite electrodes, which is applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, nanotechnology for materials and surface science, etc., and can solve problems such as fast attenuation and small actual capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 50 mg of graphene oxide, place it in 60 mL of acetonitrile for ultrasonic dispersion for 30 min to obtain a uniform graphene oxide acetonitrile solution, transfer the solution to a hydrothermal kettle, and react at 180°C for 24 h. After the reaction was completed, it was naturally cooled to room temperature, and the obtained product was suction-filtered with a No. 6 sand core funnel, washed alternately with absolute ethanol and deionized water for five times, and then dried in a vacuum oven at 60°C for 12 hours to obtain the nitrogen-doped modified product. permanent graphene (NG). The product is analyzed by X-ray photoelectron spectroscopy (XPS), and the nitrogen exists in the form of carbon-nitrogen bond, pyridine nitrogen, and pyrrole nitrogen.

Embodiment 2

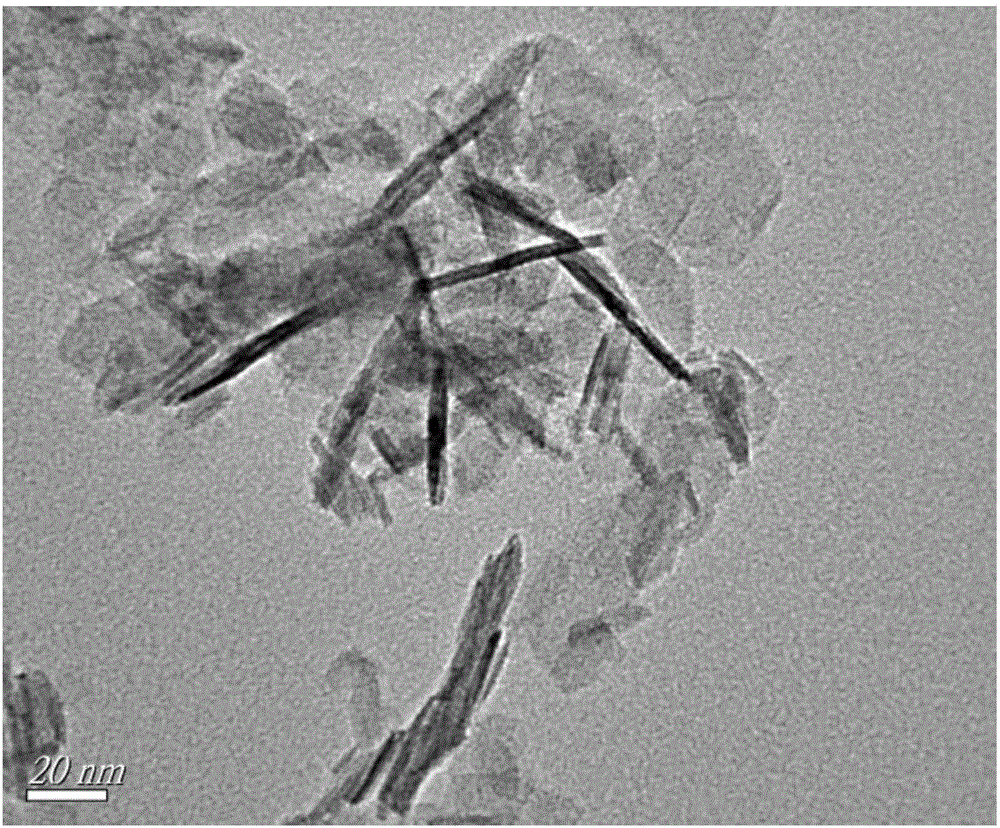

[0031] 2.9107g Co(NO 3 ) 2 ·6H 2 O(0.01mol), 1.4590g Ni(NO 3 ) 2 ·6H 2 O (0.005mol), 2.1029g of hexamethylenetetramine (0.015mol) were ultrasonically dispersed in 70ml of deionized water, and the uniformly mixed solution was transferred to a polytetrafluoroethylene hydrothermal kettle, and hydrothermally reacted at 180°C for 24h. Obtain nickel cobalt oxide precursor. After the precursor was filtered and dried, it was calcined in a tube furnace at 350 °C for 3 h under air atmosphere to obtain the product mesoporous nickel cobaltate nanomaterial NiCo 2 o 4 , mesoporous NiCo 2 o 4 It has a larger specific surface, increases the number of active sites, and is conducive to the reaction of electrolyte ions and active substances. The loose lamellar NiCo 2 o 4 It has a good skeleton support effect, provides a strong transmission channel for electrons, and is conducive to the transmission process of electrons, such as figure 2 . The nickel cobalt oxide nanomaterial prepar...

Embodiment 3

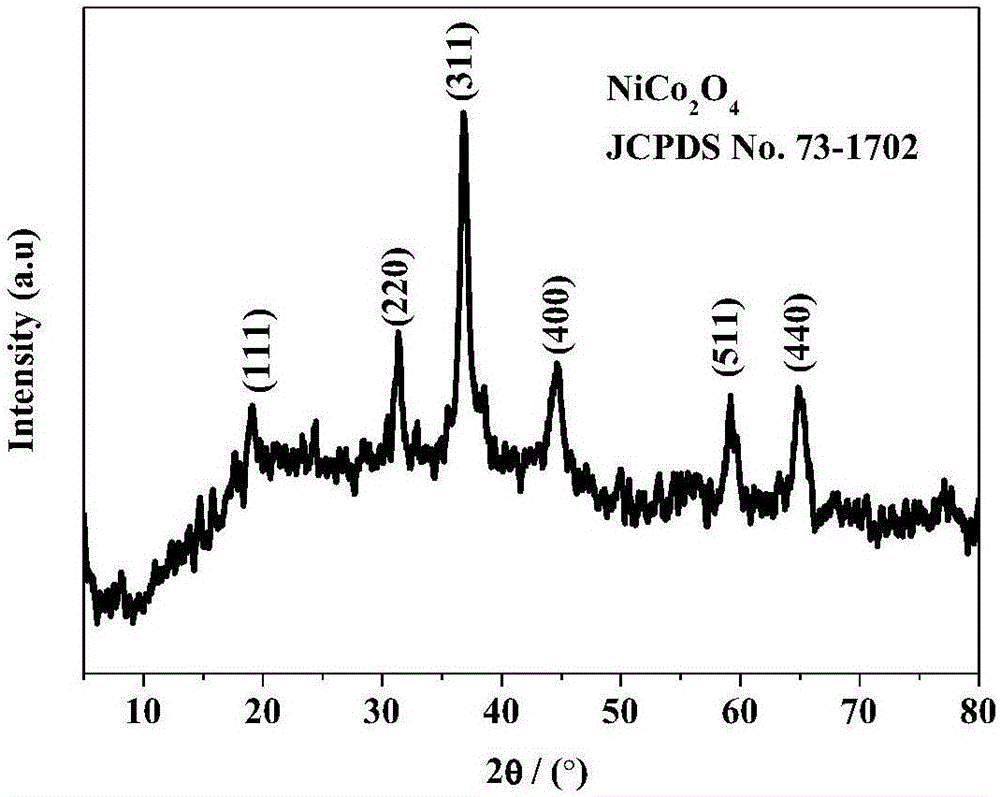

[0033] 2.9107g Co(NO 3 ) 2 ·6H 2 O(0.01mol), 1.4590g Ni(NO 3 ) 2 ·6H 2O (0.005mol), 0.1000g GO, 2.1029g hexamethylenetetramine (0.015mol) were ultrasonically dispersed in 70ml deionized water. After thermal reaction for 24h, nickel cobaltate graphene precursor was obtained. After the precursor was filtered and dried, it was calcined in a tube furnace at 350 °C for 3 h under air atmosphere to obtain the product NiCo 2 o 4 / GO, the sample has X-ray diffraction peaks at 2θ of 18.9°, 31.1°, 36.7°, 38.4°, 44.5°, 55.3°, 59.2° and 65.0°, which can be compared with NiCo 2 The standard spectra of (111), (220), (311), (222), (400), (422), (511) and (440) crystal planes of O4 crystals correspond to each other, such as figure 1 . The above-prepared NiCo 2 o 4 / GO for charge and discharge experiments with a current density of 1A g -1 , the specific capacity value reached 1800F g -1 ; After 2000 charge and discharge tests, the specific capacity remains above 87%. Figure 4 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com