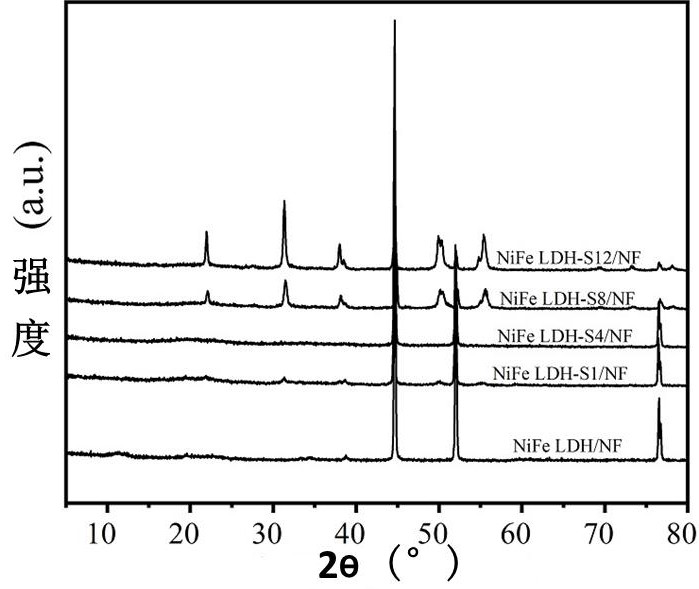

Preparation method of self-supporting ferronickel layered double hydroxide sulfide electrocatalyst

A hydroxide and sulfide electrotechnology, applied in the field of electrocatalytic materials, can solve the problems of OER catalyst resource scarcity, complex synthesis methods, and low current density, and achieve easy procurement and preparation, easy operation of the preparation process, and high conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a self-supporting nickel-iron layered double hydroxide sulfide electrocatalyst, the preparation method comprising the following steps:

[0036] Step 1, pretreating the original nickel foam to obtain purified nickel foam.

[0037] Specifically, the original nickel foam is cut into 2cm*3cm, with a thickness of 0.5mm. The above-mentioned original nickel foam is immersed in acetone and 3mol / L hydrochloric acid solution in turn and subjected to ultrasonic treatment respectively, and the ultrasonic time is about 15 minutes; then rinsed with deionized water and ethanol for 3-5 times (proper ultrasonication in the middle) to remove the surface Impurities: Dry in a vacuum drying oven at a drying temperature of 60°C and a drying time of 8 to 12 hours to obtain purified nickel foam after drying.

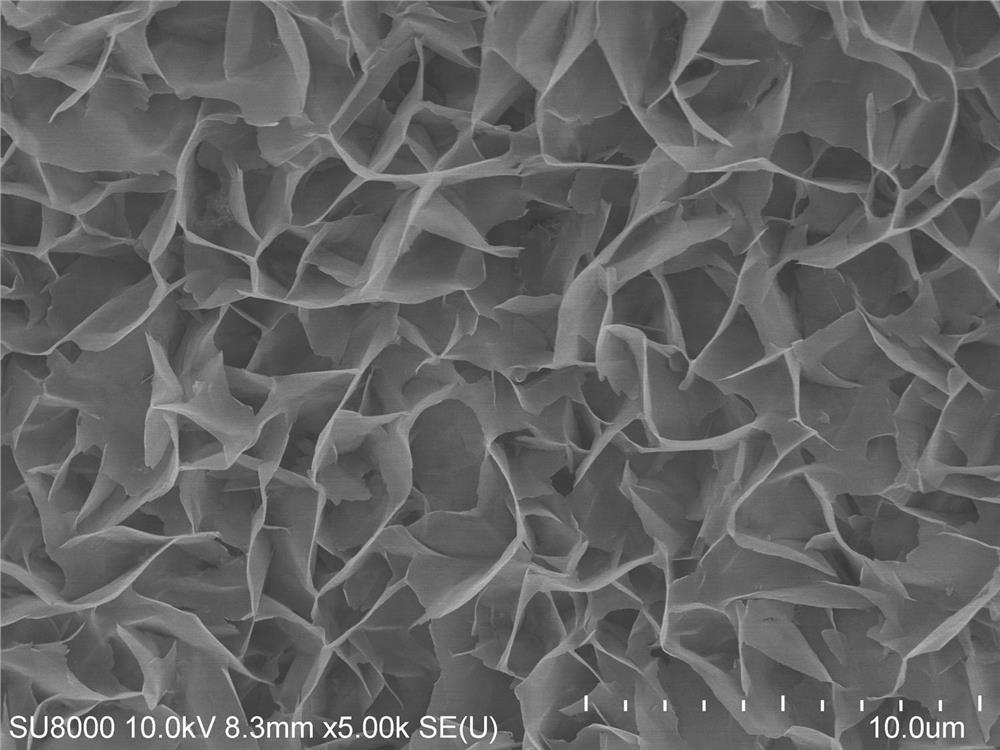

[0038] Because nickel foam has the advantages of high conductivity, large specific surface area, and porous structure, directly growing cat...

Embodiment 1

[0057] In embodiment 1, the pretreatment of foamed nickel and the process of a hydrothermal reaction are the same as those of comparative example 1, and will not be repeated here. The difference is that the secondary hydrothermal reaction, the specific process is as follows: 3mmol thioacetamide is dissolved in 30ml of deionized water, magnetically stirred for 1 hour to obtain a uniform clear solution, then poured into the lining of a stainless steel autoclave containing NiFe LDH / NF (2cm*3cm) obtained by a hydrothermal reaction, and closed the autoclave , put them into an oven at 120 °C and heat them for 1 h to carry out the secondary hydrothermal reaction. The temperature of a hydrothermal reaction can be selected but not limited to 100°C, 110°C, 120°C, 130°C and 140°C, and the heating time can be selected but not limited to 7h, 8h and 9h. After cooling to room temperature after the reaction, take out the nickel foam and rinse it with deionized water and absolute ethanol for 3...

Embodiment 2

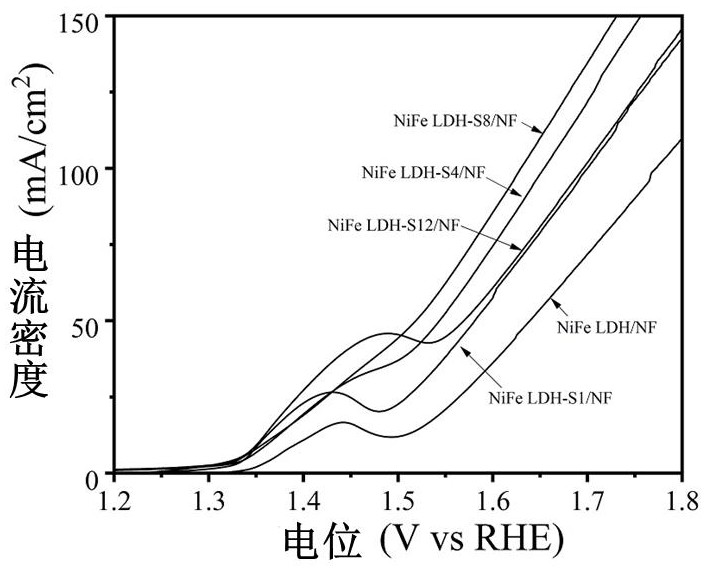

[0060] In embodiment 2, the process of the pretreatment of foam nickel, primary hydrothermal reaction and secondary hydrothermal reaction is identical with embodiment 1, does not go into details here, and its difference is the condition of secondary hydrothermal reaction, in this embodiment Among them, the conditions of the secondary hydrothermal reaction are heating temperature 120 ℃, reaction time 4h, finally get NiFe LDH-S4 / NF.

[0061] Oxygen evolution reaction (OER) catalytic performance test is the same as the test method in Comparative Example 1, the results show that when the current density is 50mA / cm 2 , the overpotential is 315mV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com