Preparation method of catalyst for ammoxidation of caprolactam

A caprolactam and catalyst technology, applied in the direction of catalyst activation/preparation, preparation of organic compounds, physical/chemical process catalysts, etc., can solve the problems of low conversion rate, low reaction temperature, low selectivity, etc., and achieve low cost and simple preparation , Preparation and easy-to-obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

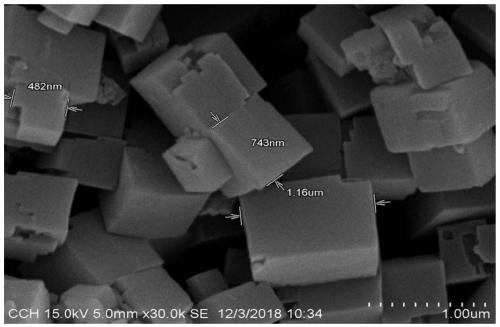

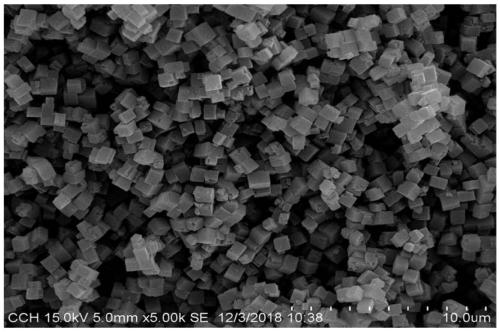

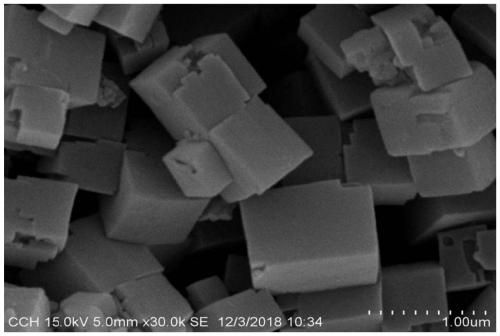

[0024] Weigh 5g of magnesium nitrate, 5g of aluminum nitrate, 1g of nickel nitrate and 150g of water to prepare a mixed solution, weigh 100g of aluminum phosphorus molecular sieve, add the aqueous solution of the active component to the aluminum phosphorus molecular sieve; After 4 hours, the water was dried under reduced pressure; the filter cake was dried at 120°C, shaped, and calcined at 550°C for 6 hours to obtain a catalyst (see Figure 1-3 ). Take 4g of the calcined catalyst and fill it in a fixed bed, heat up to 420°C, dissolve the caprolactam with acetonitrile and feed it at a space velocity of 0.5h-1, cool and collect the reaction solution, take a sample and control it, the conversion rate of the raw material caprolactam is 81%, and the product The selectivity of 6-aminocapronitrile is greater than 99.0%.

Embodiment 2

[0026] Weigh 7g of magnesium nitrate, 7g of aluminum nitrate, 1g of nickel nitrate and 170g of water to prepare a mixed solution, weigh 100g of aluminum phosphorus molecular sieve, and add the aqueous solution of the active component to the aluminum phosphorus molecular sieve; After 4 hours, the water was dried under reduced pressure; the filter cake was dried at 120° C., shaped, and calcined at 550° C. for 5 hours to obtain the catalyst. Take 4g of the calcined catalyst and fill it in a fixed bed, raise the temperature to 450°C, dissolve the caprolactam in acetonitrile and feed it at a space velocity of 0.5h-1, cool and collect the reaction solution, take a sample and control it, the conversion rate of the raw material is 82.2%, the selectivity Greater than 99.0%.

Embodiment 3

[0028] Weigh 9g of magnesium nitrate, 9g of aluminum nitrate, 2g of nickel nitrate and 200g of water to prepare a mixed solution, weigh 100g of aluminum phosphorus molecular sieve, add the aqueous solution of the active component to the aluminum phosphorus molecular sieve; After 4 hours, the water was dried under reduced pressure; the filter cake was dried at 120°C, shaped, and calcined at 550°C for 6 hours to obtain the catalyst. Take 4g of the calcined catalyst and fill it in a fixed bed, raise the temperature to 420°C, dissolve the caprolactam in acetonitrile and feed it at a space velocity of 0.5h-1, cool and collect the reaction liquid, take a sample and control it, the conversion rate of the raw material is 82.2%, the selectivity Greater than 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com