Photocatalyst and its preparing process

A photocatalyst and activation treatment technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems affecting applications and achieve the goal of increasing hydrogen production rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

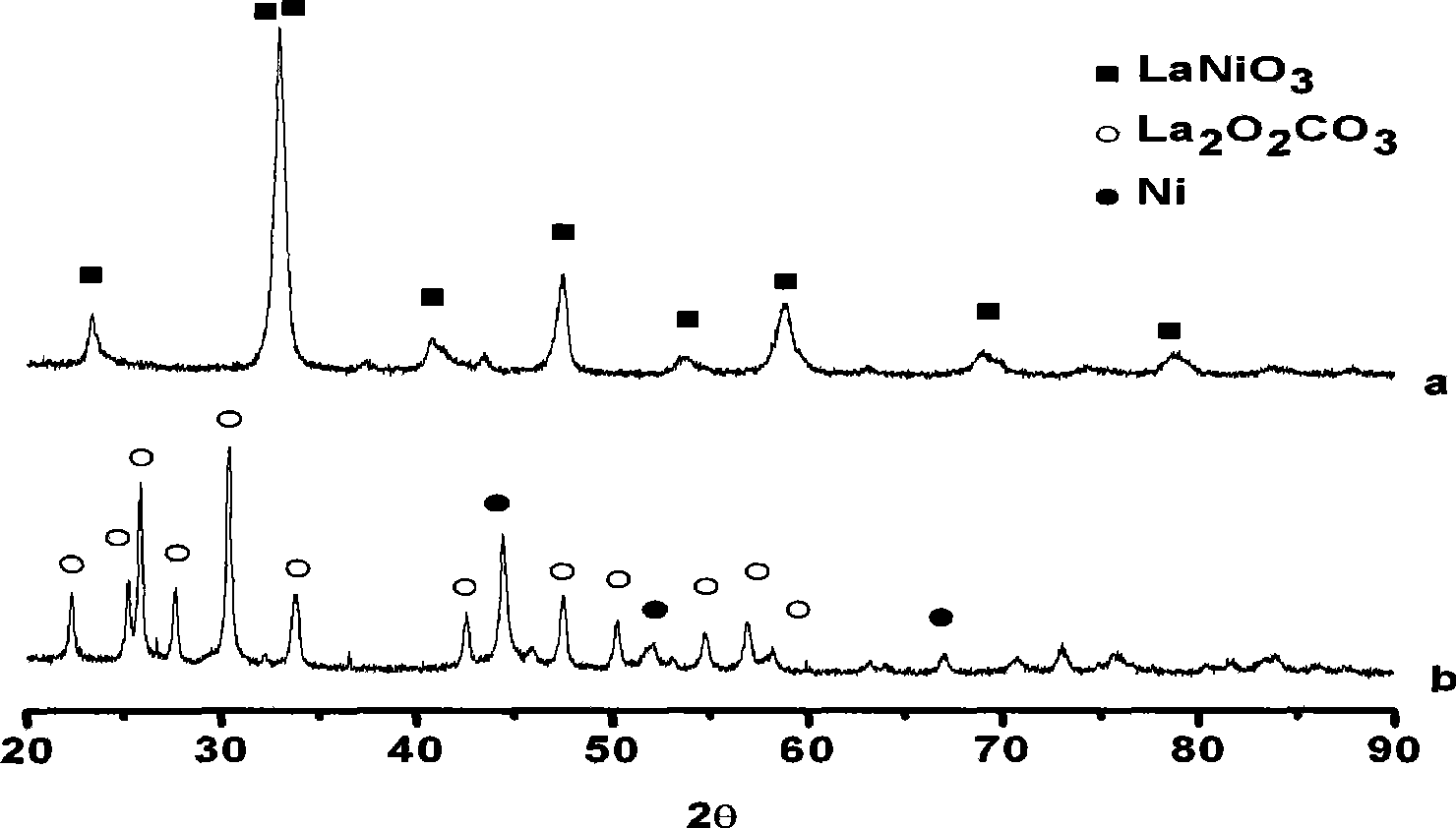

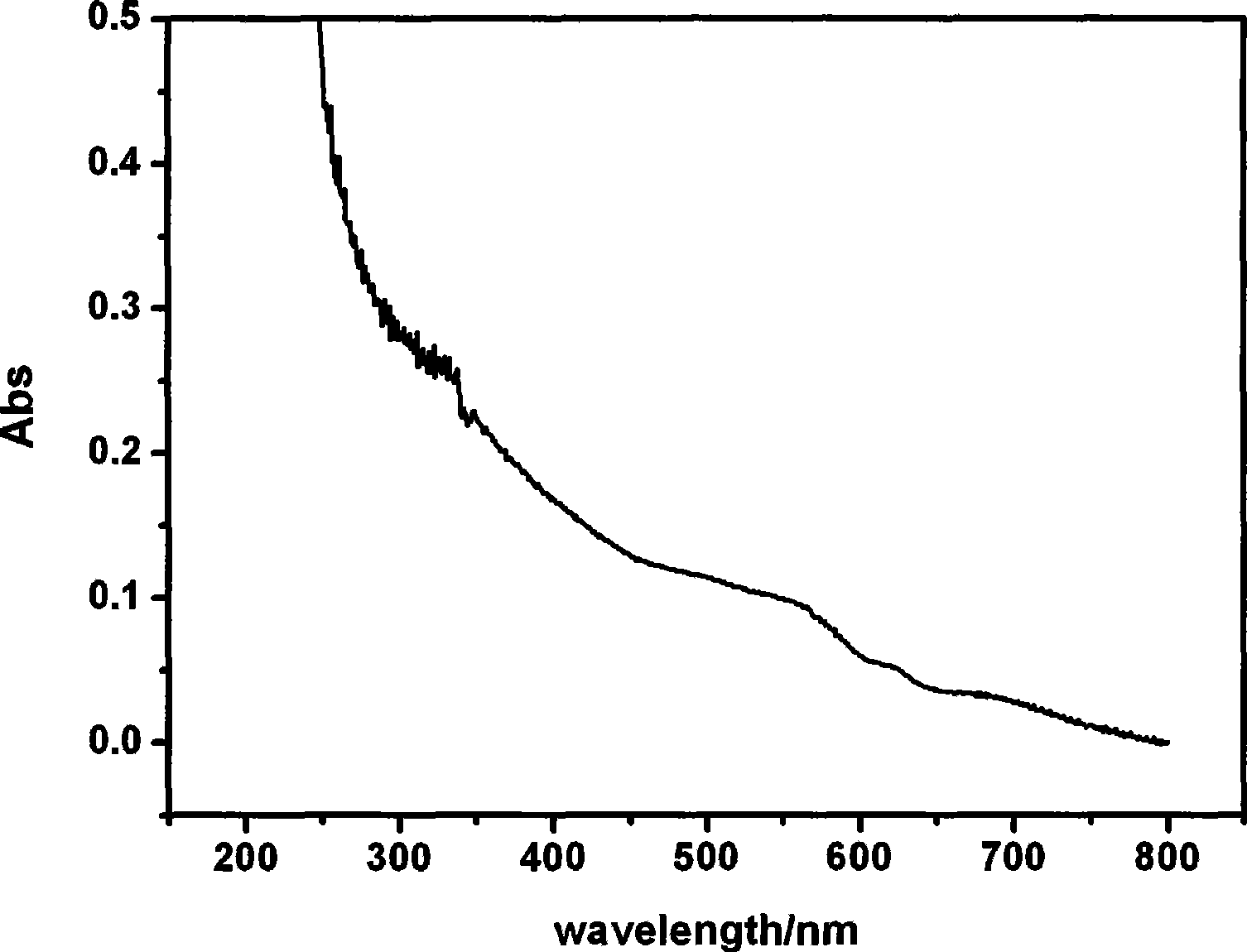

[0017] Embodiment 1: preparation concentration is respectively 0.5mol / L lanthanum nitrate solution and cobalt nitrate solution, in molar ratio, La: Co: citric acid=1: 1: 0.6, lanthanum nitrate solution and cobalt nitrate solution are mixed with citric acid, Gel was formed under the irradiation of infrared lamps, precalcined at 400°C for 2 hours, and calcined at 800°C for 4 hours to obtain perovskite LaNiO 3 . NeO 3 The activation treatment is carried out in a small fixed-bed reactor, under normal pressure, the activation temperature is 600°C, and the activation gas is CO in molar ratio. 2 :H 2 =1:3, activation volume space velocity 2100h -1 , activation time 3h, to get Ni / La 2 o 2 CO 3 . Perovskite LaNiO 3 For XRD patterns before and after activation, see figure 1 , Ni / La 2 o 2 CO 3 UV-Vis Diffuse Reflectance Spectrum See figure 2 .

[0018] 0.1g Ni / La 2 o 2 CO 3 Catalyst and 100ml deionized water were put into the reactor, the reaction was carried out under ...

Embodiment 2

[0021] Embodiment 2: prepare respectively lanthanum nitrate and nickel nitrate concentration and be 0.2mol / L solution, in molar ratio, La: Ni: citric acid=1: 1: 2, lanthanum nitrate solution and nickel nitrate solution are mixed with citric acid, in A gel is formed under the irradiation of an infrared lamp, precalcined at 380°C for 2 hours, and calcined at 750°C for 4 hours to obtain the perovskite LaNiO 3 , LaNiO 3 Activation is carried out in a small fixed bed reactor, the activation pressure is 2MPa, the activation temperature is 500°C, and the activation gas is CO in molar ratio. 2 :H 2 =1:4, activation volume space velocity 3000h -1 , activation time 6h, to get Ni / La 2 o 2 CO 3

[0022] For photocatalytic activity evaluation, take 0.3g photocatalyst and put it into the reactor, and feed 40ml / min CO continuously before the reaction 2 , 60min, all the other are with embodiment 1. The yields of hydrogen production and carbon dioxide reduction to formic acid and forma...

Embodiment 3

[0023] Embodiment 3: prepare respectively lanthanum nitrate and nickel nitrate concentration and be 0.4mol / L solution, by molar ratio, La: Ni: citric acid=1: 1: 1.2, get a certain amount of lanthanum nitrate solution and nickel nitrate solution and citric acid Mixing, forming a gel under the irradiation of infrared lamps, pre-calcining at 400°C for 2 hours, and roasting at 750°C for 4 hours to obtain perovskite LaNiO 3 , LaNiO 3 Activation is carried out in a small fixed-bed reactor, the activation pressure is 1MPa, the activation temperature is 700°C, and the activation gas is CO in molar ratio. 2 :H 2 =1:5, activation hourly space velocity 2500h -1 , activation time 4h, to get Ni / La 2 o 2 CO 3

[0024] For photocatalytic activity evaluation, take 0.2g of photocatalyst and put it into the reactor, and feed 80ml / min CO continuously before the reaction 2 , 30min, all the other are with embodiment 1. The yields of hydrogen production and carbon dioxide reduction to formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com