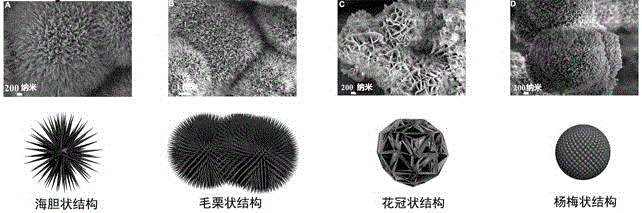

Morphology-controlled carbon quantum dot/nickel cobaltate composite electrode material and preparation method

A carbon quantum dot and composite electrode technology, applied in the field of nanomaterials, can solve the problems of limited effect, expensive composite raw materials, and limited sources, and achieve the effects of simple preparation method, improved rate performance, and improved cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of carbon quantum dots with ethylenediamine and citric acid as raw materials

[0031] 0.1g of citric acid, 300μL of ethylenediamine and 500μL of water were added to a 50mL polytetrafluoroethylene-lined reactor, and reacted at 140°C for 4 hours. After cooling to room temperature, distilled water was added to form an aqueous solution of carbon quantum dots. Add ethanol to the aqueous solution for sedimentation to obtain a flocculent solid, collect the solid precipitate, rinse with ethanol for 2-3 times, put it into a vacuum oven at 40°C for drying, and obtain a tan powder.

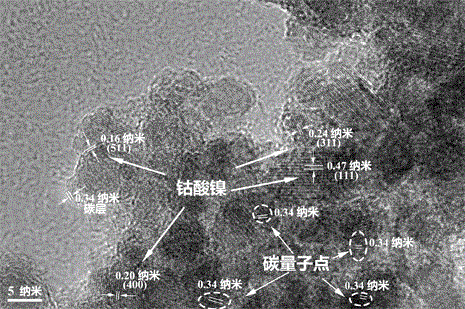

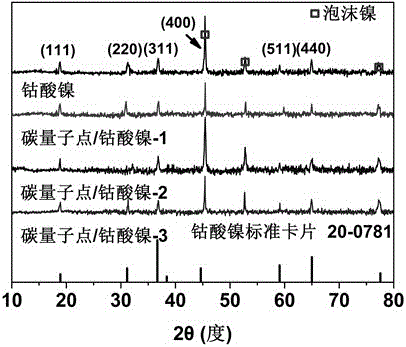

[0032] (2) Preparation of carbon quantum dots / nickel cobalt oxide composites

[0033] 1 mmol nickel nitrate hexahydrate (analytical pure), 2 mmol cobalt nitrate hexahydrate (analytical pure) and various amounts of the above carbon amounts

[0034] Subdot powder (W= 10, 20 and 40 mg) was dissolved in 20ml of water and 20ml of ethanol to form a pink clear mixture, then added 12 mmol of ...

Embodiment 2

[0036] (1) Preparation of carbon quantum dots using p-phenylenediamine as raw material

[0037] First measure 5ml of ethanol and put it into a 50ml centrifuge tube, then weigh 0.2g of urea (analytical pure) and 0.2g of untreated

[0038] Oxidized p-phenylenediamine (analytical pure) was quickly added into the centrifuge tube and shaken until completely dissolved to form a reddish-brown solution. Then add 45ml of deionized water, mix well, transfer the mixture to a high-pressure reactor (150 ml), and keep it sealed. First preheat the high-temperature oven to 160°C, then put the reaction kettle into the oven to react for 10 hours, after the reaction is completed, cool down to room temperature naturally. The obtained solution was settled and purified with dilute ammonia water to obtain a pure carbon quantum dot solution, and then vacuum-dried at 40° C. to obtain dark brown carbon quantum dot powder.

[0039] (2) Preparation of carbon quantum dots / nickel cobalt oxide composites ...

Embodiment 3

[0042] (1) Preparation of carbon quantum dots from polyvinylpyrrolidone

[0043] First put 1g of polyvinylpyrrolidone (K-30, analytically pure) into the quartz boat of the tube furnace, and then set the temperature at

[0044] It rises from room temperature to 400°C within 100 minutes, calcines the sample for 3 hours, and naturally drops to room temperature after the reaction. The whole process is completed by exposing to air. Subsequently, the bulk sample obtained for the first time was ground into powder, and then 30 mL of ethanol was added for ultrasonic precipitation. After that, the ethanol liquid was taken for centrifugal purification (15,000 r / min), distillation and other treatments, and finally the carbon dot solid powder was obtained.

[0045] (2) Preparation of carbon quantum dots / nickel cobalt oxide composites

[0046] 0.8 mmol nickel nitrate hexahydrate (analytical pure), 1.6 mmol cobalt nitrate hexahydrate (analytical pure) and different amounts of the above car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com