Preparation method of capacitor electrode material beta-NiMoO4 and super capacitor

A technology for capacitor electrodes and supercapacitors, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of complex preparation methods, inconvenient use, and difficult storage, and achieve simple operation steps, long cycle life, Effects that are easy to store

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A capacitor electrode material β-NiMoO 4 The preparation method:

[0037] 1. Add 0.025mol sodium molybdate dihydrate and 0.025mol nickel nitrate hexahydrate to 14ml ultrapure water, add ammonia water to 3ml ultrapure water, adjust to 8, add the 3ml ultrapure water with ammonia water to the above mixture In the solution, adjust the pH between 7-8, stir and mix until the solution is clear.

[0038] 2. Place the plain carbon cloth and / or carbon fiber soaked in the potassium permanganate solution in a closed reaction vessel, then add the mixed solution in step (1), and seal it. The sealed carbon fiber is extracted from the carbon cloth. The thickness of the carbon cloth is 0.5mm, and the area is 2cm×3cm. The airtight reaction vessel is made of materials resistant to acid, alkali, high temperature and high pressure. This experiment uses Teflon tube.

[0039] 3. Place the Teflon tube prepared in step 2 in a heating device capable of constant temperature control (such as muf...

Embodiment 2

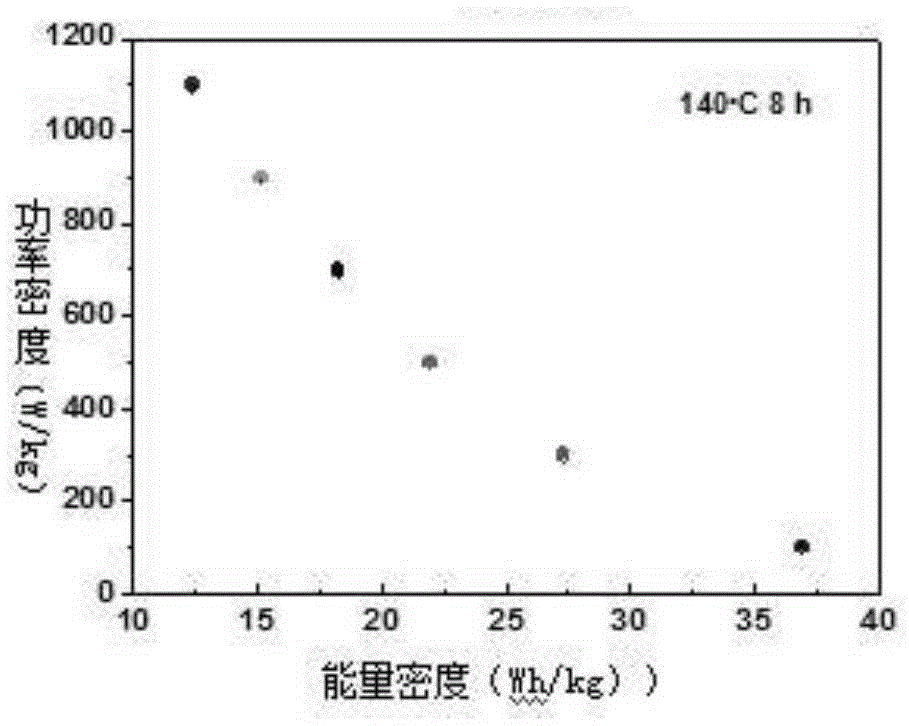

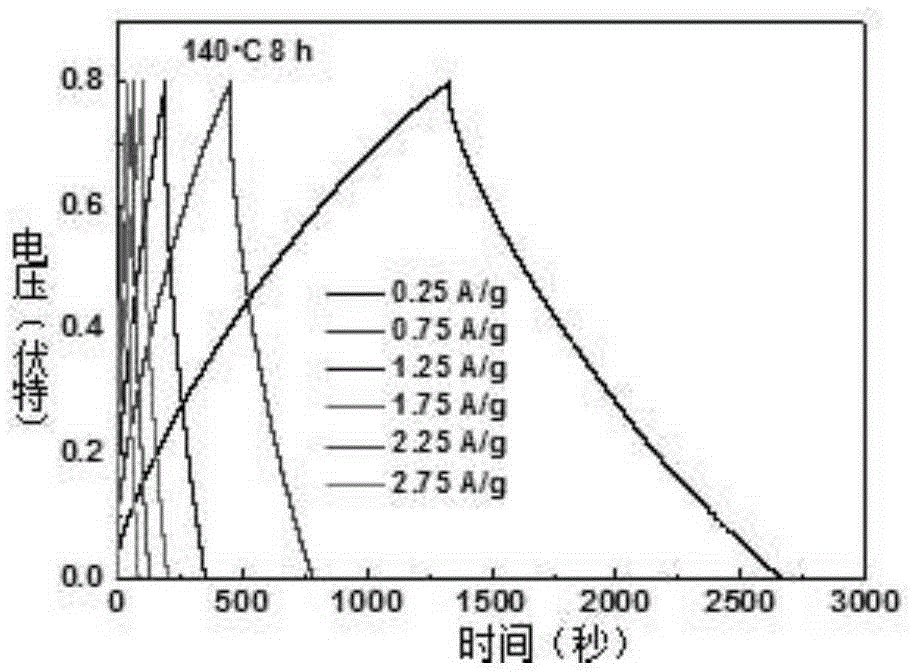

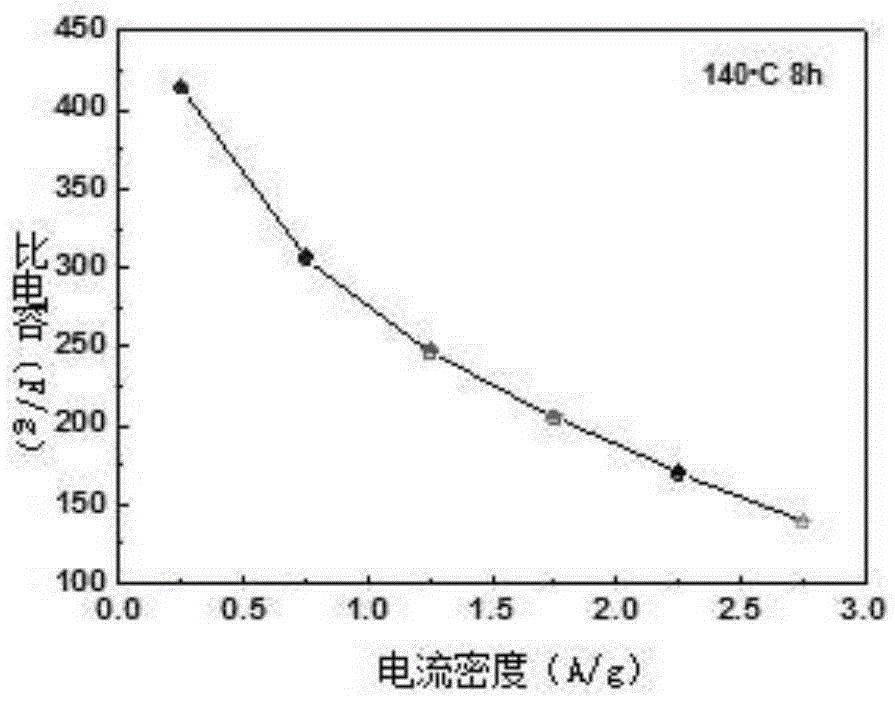

[0042] Growth of β-NiMoO tightly wound in the middle of the carbon rod 4 carbon fiber nanowires, were grown on β-NiMoO 4 The length of the carbon rod wound by the carbon fiber of the nanowire is 2cm, and the polyvinyl alcohol-lithium chloride electrolyte is coated on the carbon fiber, and then a circle of diaphragm is wound outside the carbon fiber, and then the polyvinyl alcohol-lithium chloride electrolyte is coated with Growth of β-NiMoO 4The carbon cloth of nanowires is wound on the outer surface of the separator to obtain a wound supercapacitor. Its charge and discharge performance is shown in Figure 3(a). When the current density is 0.75A / g, it can be seen that the growth time is the longest and the performance is the best when the discharge is 8h. As shown in Figure 3(b), when the current density is 0.25A / g, the discharge time can reach 1331 seconds. Figure 3(c) knows that the maximum specific capacitance can reach 414F / g. Figure 3(d) The energy density can reach up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com