Nano-nickel catalyst loaded on grapheme and preparation method thereof

A technology of graphene and nano-nickel, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of increasing the production cost of nano-nickel, large nickel particle size, Environmental pollution and other problems, to avoid catalyst activity, concentrated size distribution, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

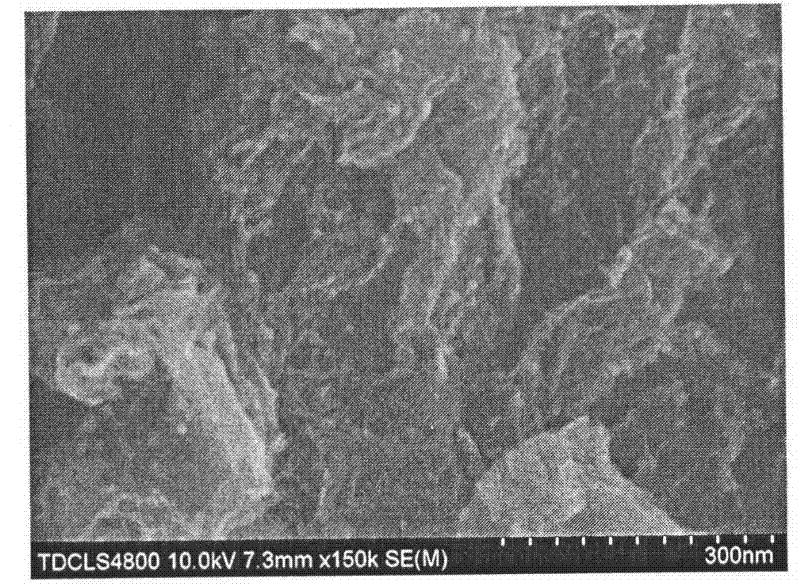

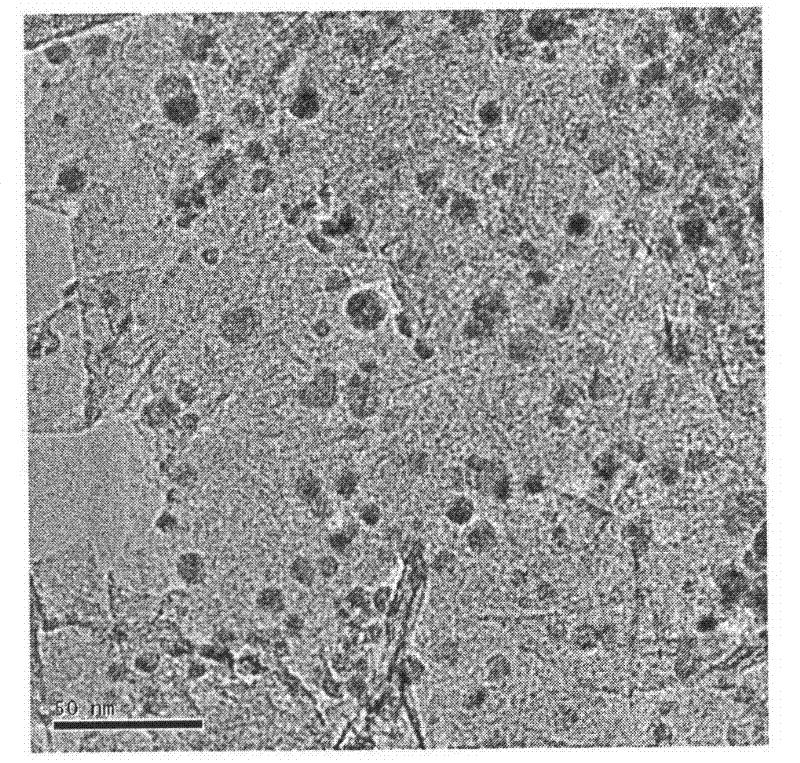

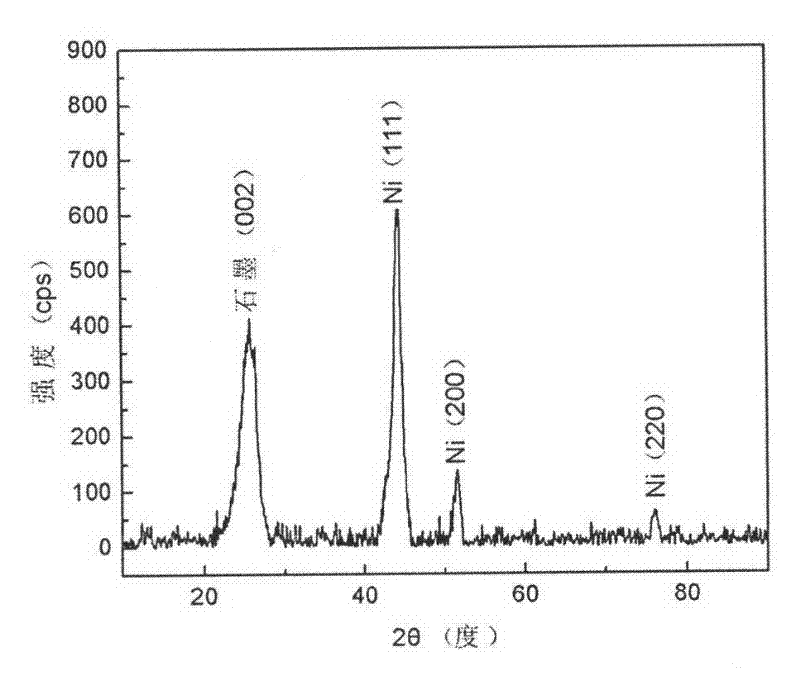

[0016] Add 3g of natural flake graphite to 120ml of sulfuric acid with a mass concentration of 98%, and slowly add 15g of potassium permanganate while stirring the mixture at a rate of 200rpm in an ice-water bath; During the process, continue to stir for 1 hour; raise the temperature of the water bath to 65°C and stir for 2 hours, while stirring, slowly add 250ml of deionized water, add deionized water to the resulting mixture to 1400ml, then add 30ml of hydrogen peroxide with a mass concentration of 30%, and react 20min. The resulting product was centrifuged and washed with dilute hydrochloric acid with a mass concentration of 5%, until no SO 4 2- (with BaCl 2 test), the obtained washings were dried at a temperature of 60°C in a vacuum drying oven to obtain graphite oxide; 100 mg of graphite oxide prepared in the above steps was dispersed in 100 ml of deionized water, and ultrasonically peeled for 2 hours to obtain graphite oxide with a concentration of 1 mg / ml Alkene solu...

Embodiment 2

[0020] The process of preparing the nano-nickel catalyst supported on graphene in this embodiment is the same as that of Example 1, except that the nickel nitrate hexahydrate that is dissolved in 55 ml of ethanol solution with a volume concentration of 50% is changed from 55 mg to 22.5 mg. mg, and finally prepare nano-nickel loaded on graphene, the loading amount of nano-nickel is 5wt.%, and the average particle size of nano-nickel is 5-10nm.

Embodiment 3

[0022] The process of preparing the nano-nickel catalyst loaded on graphene in this embodiment is the same as that of Example 1, except that the nickel nitrate hexahydrate that is dissolved in 55ml volume concentration of 50% ethanol solution is changed from 55mg to 16.5 mg, and finally prepare nano-nickel loaded on graphene, the loading amount of nano-nickel is 5wt.%, and the average particle size of nano-nickel is 5-10nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com