PtNi/C bimetallic catalyst and preparation method thereof

A bimetallic catalyst, catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of limited application and high price of Pt, and achieve the The effect of conversion rate, efficiency improvement, and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

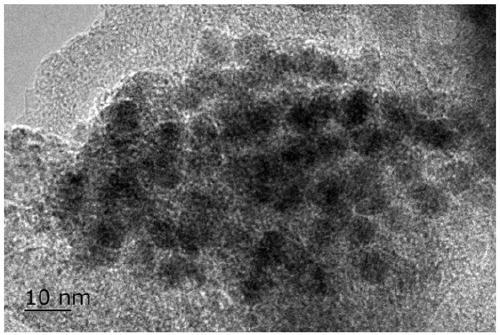

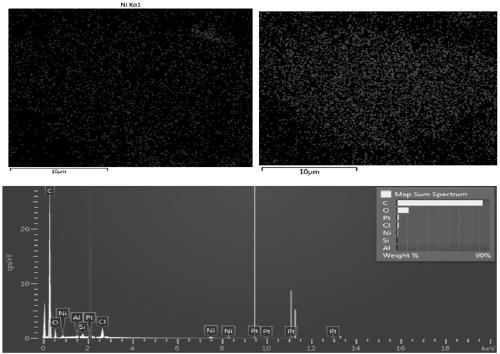

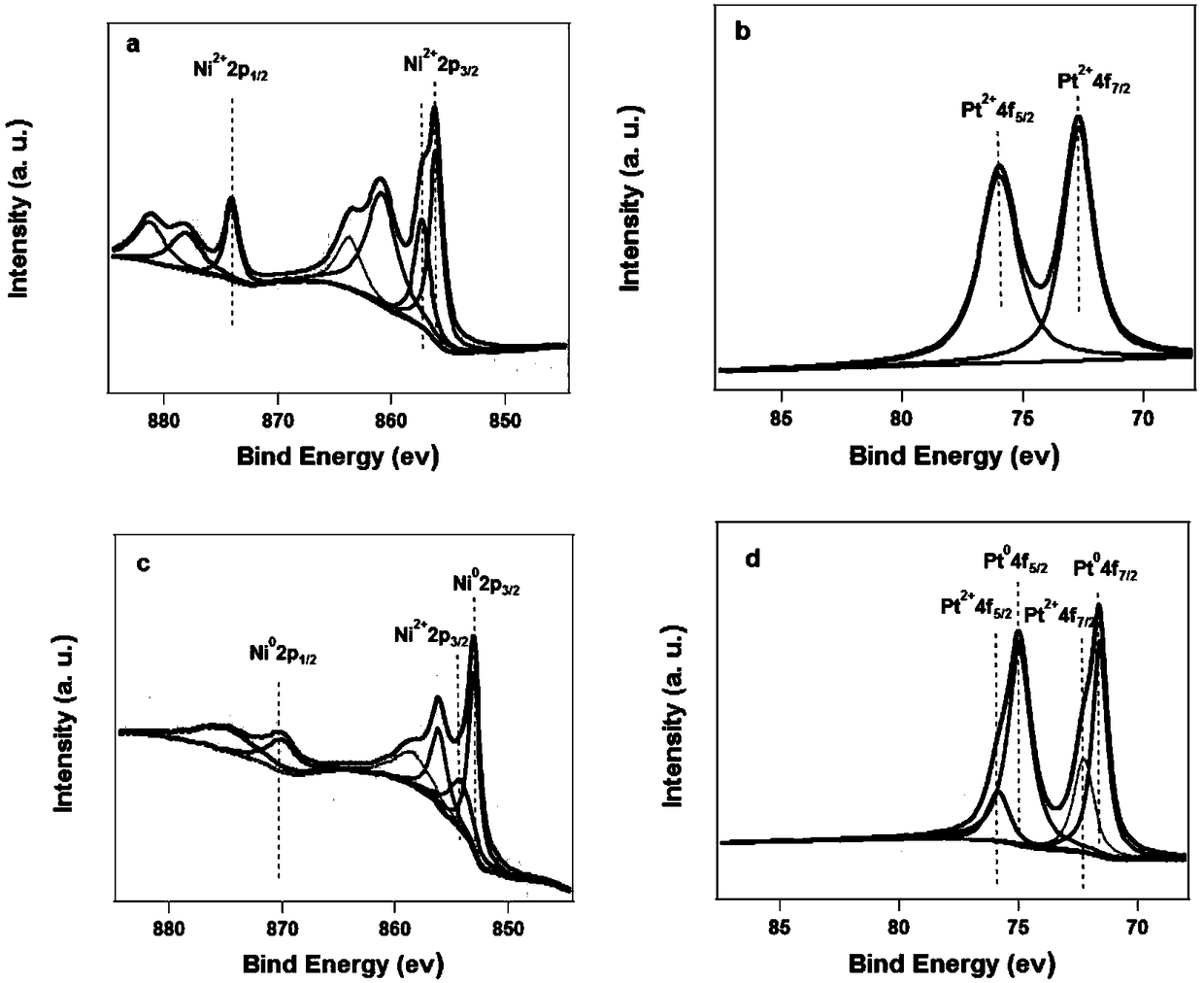

[0028] The preparation method of PtNi / C catalyst specifically comprises the steps:

[0029] (1) Weigh 50g of activated carbon to elute the dust in boiling deionized water for 2h, add 400mL of nitric acid solution with a mass fraction of 10% after centrifugation, stir at 80°C for 5h, filter and wash the activated carbon with water until pH = 7, 60°C dry overnight;

[0030] (2) Add 1 g of activated carbon treated in step (1) into 20 mL of deionized water, then add 0.08 g of chloroplatinic acid and 0.148 g of nickel nitrate into the activated carbon aqueous solution, stir at room temperature for 24 h, centrifuge and dry overnight at 60 ° C , to obtain the catalyst precursor;

[0031] (3) Reducing the catalyst precursor obtained in step (2) in a hydrogen atmosphere at 400° C. for 2 h to obtain a Pt(3)Ni(3) / C catalyst.

Embodiment 2

[0033] The preparation method of PtNi / C catalyst specifically comprises the steps:

[0034] (1) Weigh 50g of activated carbon to elute the dust in boiling deionized water for 2h, add 400mL of nitric acid solution with a mass fraction of 10% after centrifugation, stir at 80°C for 3h, filter and wash the activated carbon with water until pH = 7, 60°C dry overnight;

[0035] (2) Add 1 g of activated carbon treated in step (1) into 20 mL of deionized water, then add 0.08 g of chloroplatinic acid and 0.148 g of nickel nitrate into the activated carbon aqueous solution, stir at room temperature for 24 h, centrifuge and dry overnight at 60 ° C , to obtain the catalyst precursor;

[0036] (3) Reducing the catalyst precursor obtained in step (2) at 450° C. for 1 h in a hydrogen atmosphere to obtain a Pt(3)Ni(3) / C catalyst.

Embodiment 3

[0038] The preparation method of PtNi / C catalyst specifically comprises the steps:

[0039] (1) Weigh 50g of activated carbon to elute the dust in boiling deionized water for 2 hours, add 400mL of nitric acid solution with a mass fraction of 10% after centrifugation, stir at 80°C for 4h, filter and wash the activated carbon with water until pH = 7, 60°C dry overnight;

[0040] (2) Add 1 g of activated carbon treated in step (1) into 20 mL of deionized water, then add 0.08 g of chloroplatinic acid and 0.148 g of nickel nitrate into the activated carbon aqueous solution, stir at room temperature for 24 h, centrifuge and dry overnight at 60 ° C , to obtain the catalyst precursor;

[0041] (3) Reducing the catalyst precursor obtained in step (2) in a hydrogen atmosphere at 350° C. for 3 h to obtain a Pt(3)Ni(3) / C catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com