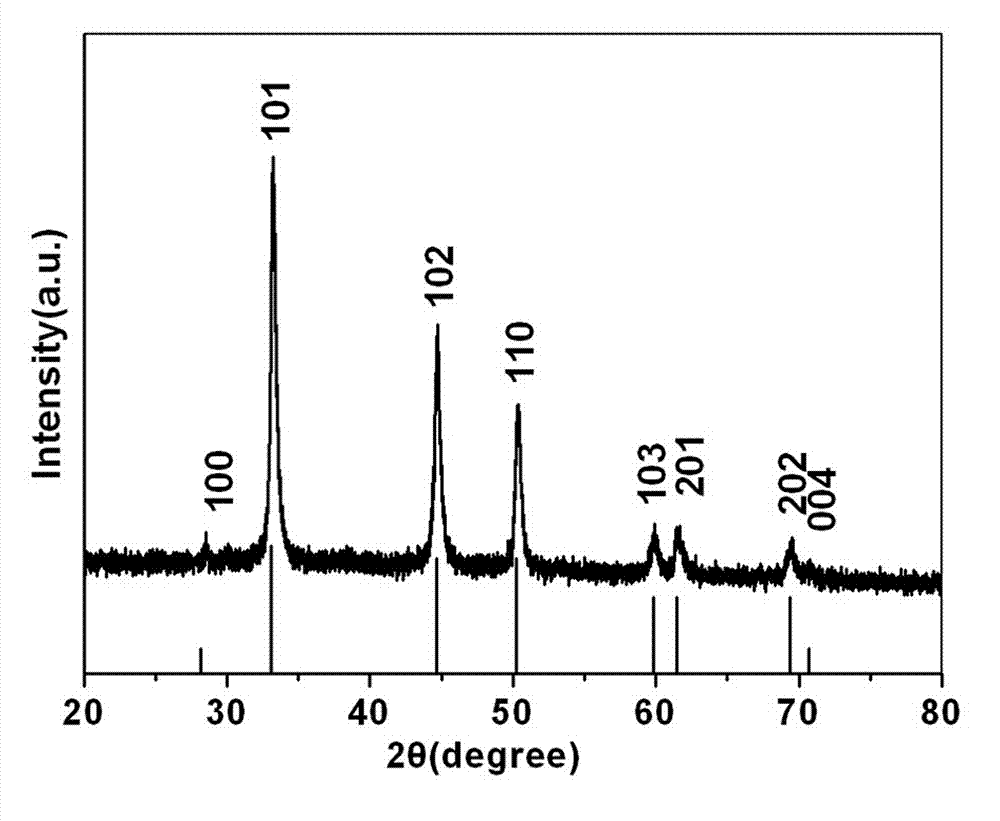

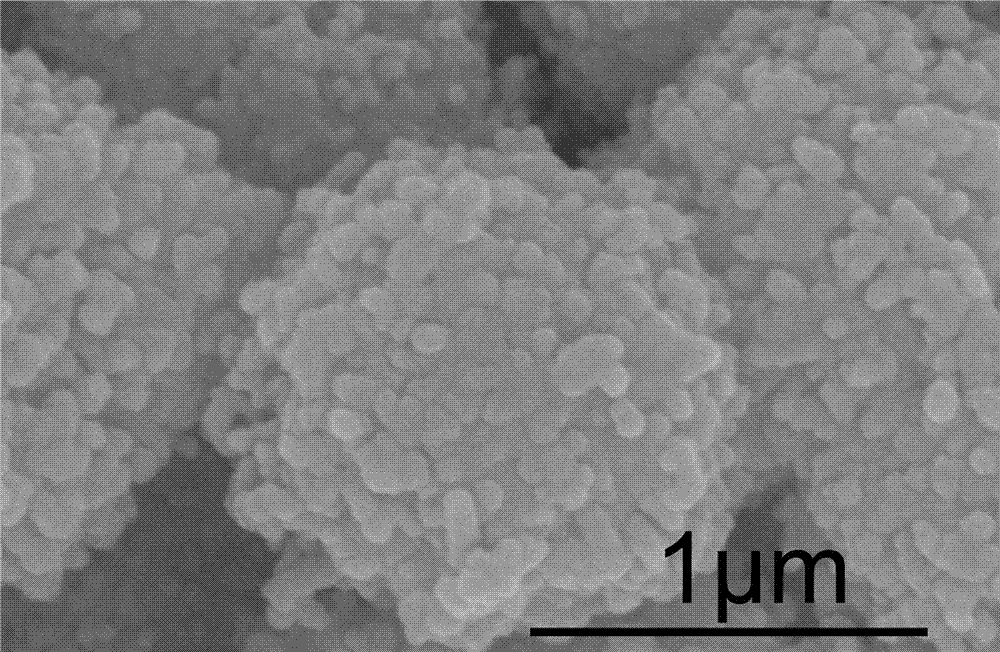

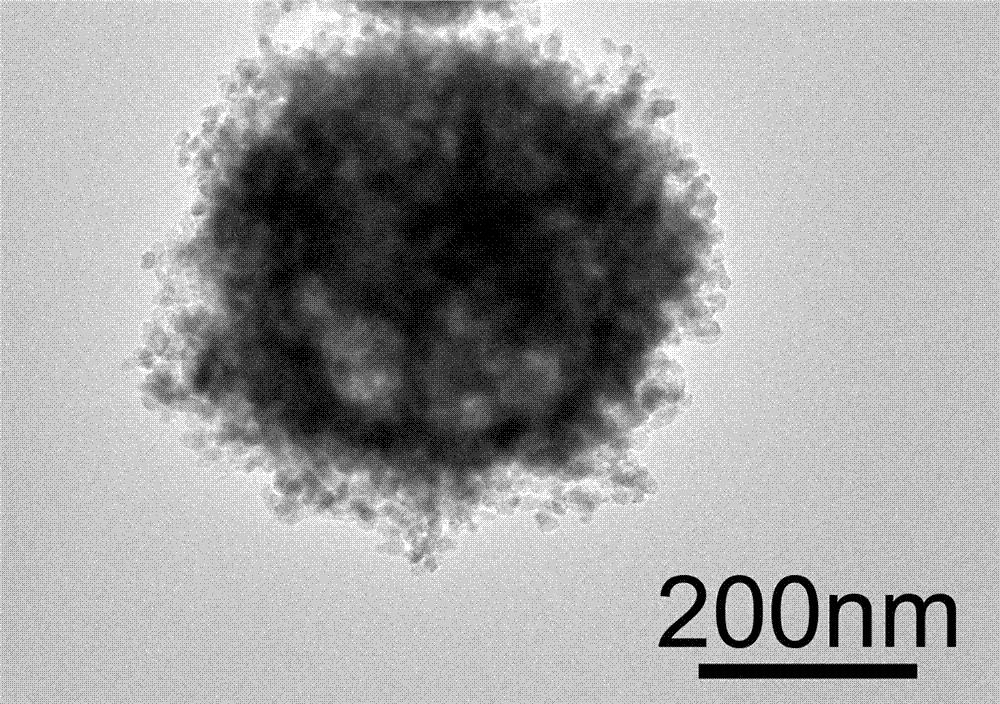

Preparation method of porous nickel selenide hollow nanospheres

A nickel selenide, hollow sphere technology, applied in nanotechnology, nanotechnology, binary selenium/tellurium compounds, etc., can solve problems such as environmental impact, and achieve the effects of reducing energy consumption, facilitating mass production, and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of porous nickel selenide nanometer hollow spheres comprises the following steps:

[0028] Step A, selenium dioxide, nickel nitrate and deionized water are mixed and stirred quickly according to the ratio of selenium dioxide: nickel nitrate: deionized water: 1mmol: 1mmol: 18mL, to obtain a transparent clear liquid;

[0029] Step B, add 10mL concentrated ammonia water (25%~28%), stir and make it evenly mixed;

[0030] Step C, add 12mL hydrazine hydrate (85%), stir and make it evenly mixed;

[0031] Step D, transfer the mixed system to a polytetrafluoroethylene-lined reaction kettle, keep the temperature at 180° C. for 2 hours, and cool naturally to obtain a hydrothermal product;

[0032] Step E, centrifuging the hydrothermal product described in step D, washing with absolute ethanol and deionized water three times;

[0033] Step F, vacuum-dry the product obtained in step E at 80° C. for 12 hours to obtain porous nickel selenide hollow nanospheres.

[0...

Embodiment 2

[0041] The preparation of porous nickel selenide nanometer hollow spheres comprises the following steps:

[0042] Step A, selenium dioxide, nickel nitrate and deionized water are mixed and stirred quickly according to the ratio of selenium dioxide: nickel nitrate: deionized water: 1mmol: 1mmol: 20mL, to obtain a transparent clear liquid;

[0043] Step B, add 8mL concentrated ammonia water (25%~28%), stir and make it evenly mixed;

[0044] Step C, add 12mL hydrazine hydrate (85%), stir and make it evenly mixed;

[0045] Step D, transfer the mixed system to a polytetrafluoroethylene-lined reaction kettle, keep the temperature at 140° C. for 2 hours, and cool naturally to obtain a hydrothermal product;

[0046] Step E, centrifuging the hydrothermal product described in step D, washing with absolute ethanol and deionized water three times;

[0047] Step F, vacuum-dry the product obtained in step E at 60°C for 12 hours to obtain porous nickel selenide hollow nanospheres.

Embodiment 3

[0049] The preparation of porous nickel selenide nanometer hollow spheres comprises the following steps:

[0050]Step A, selenium dioxide, nickel nitrate and deionized water are mixed and stirred quickly according to the ratio of selenium dioxide: nickel nitrate: deionized water: 1mmol: 2mmol: 20mL, to obtain a transparent clear liquid;

[0051] Step B, add 10mL concentrated ammonia water (25%~28%), stir and make it evenly mixed;

[0052] Step C, add 10mL hydrazine hydrate (85%), stir and make it evenly mixed;

[0053] Step D, transfer the mixed system to a polytetrafluoroethylene-lined reaction kettle, keep the temperature at 180° C. for 2 hours, and cool naturally to obtain a hydrothermal product;

[0054] Step E, centrifuging the hydrothermal product described in step D, washing with absolute ethanol and deionized water three times;

[0055] Step F, vacuum-dry the product obtained in step E at 80° C. for 12 hours to obtain porous nickel selenide hollow nanospheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com