Bimetallic nano-phosphate based on metal-organic framework and preparation method and application thereof

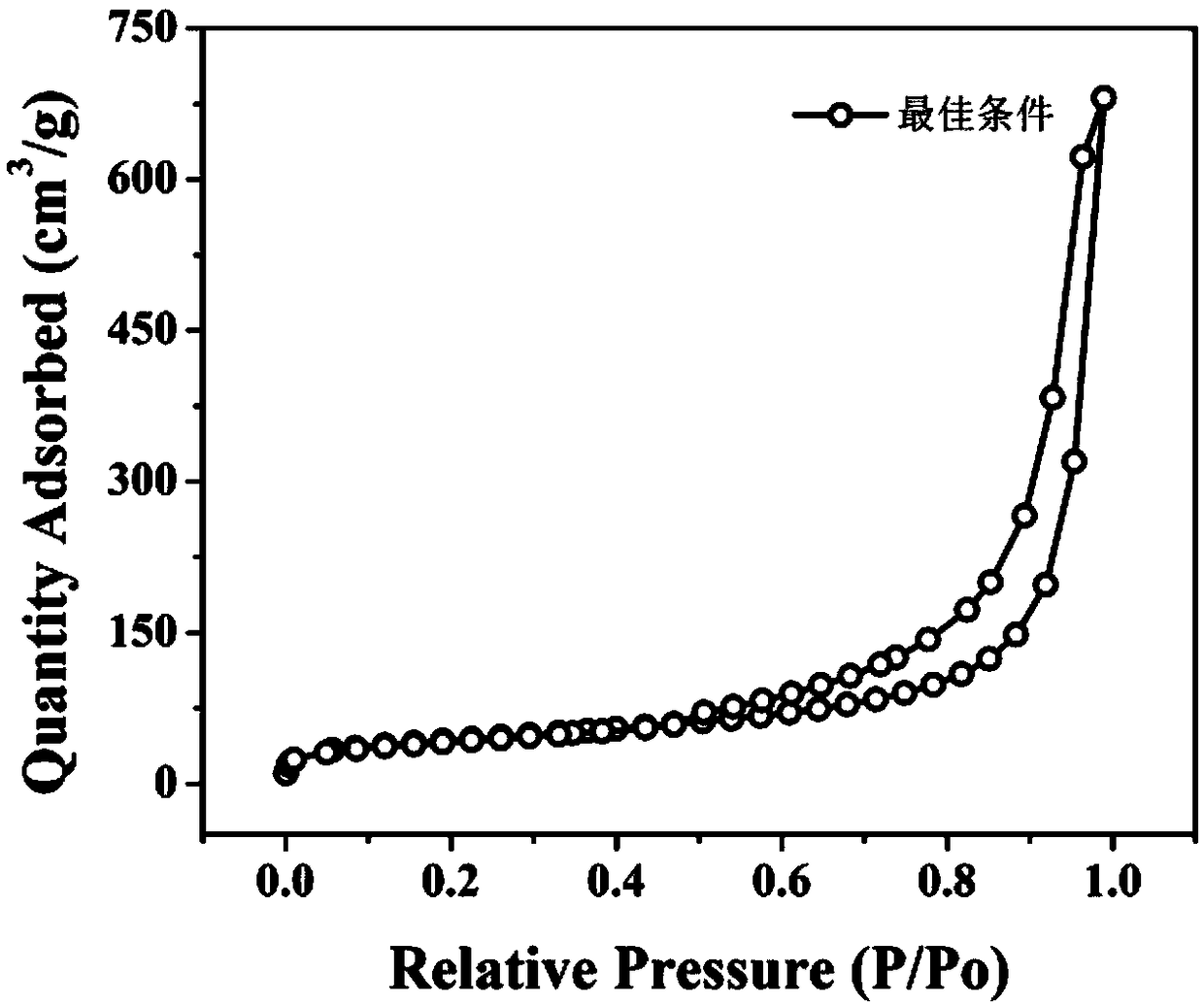

A bimetallic nano-organic framework technology, applied in the field of materials, can solve problems such as high energy consumption, and achieve the effects of avoiding energy consumption, increasing specific surface area, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

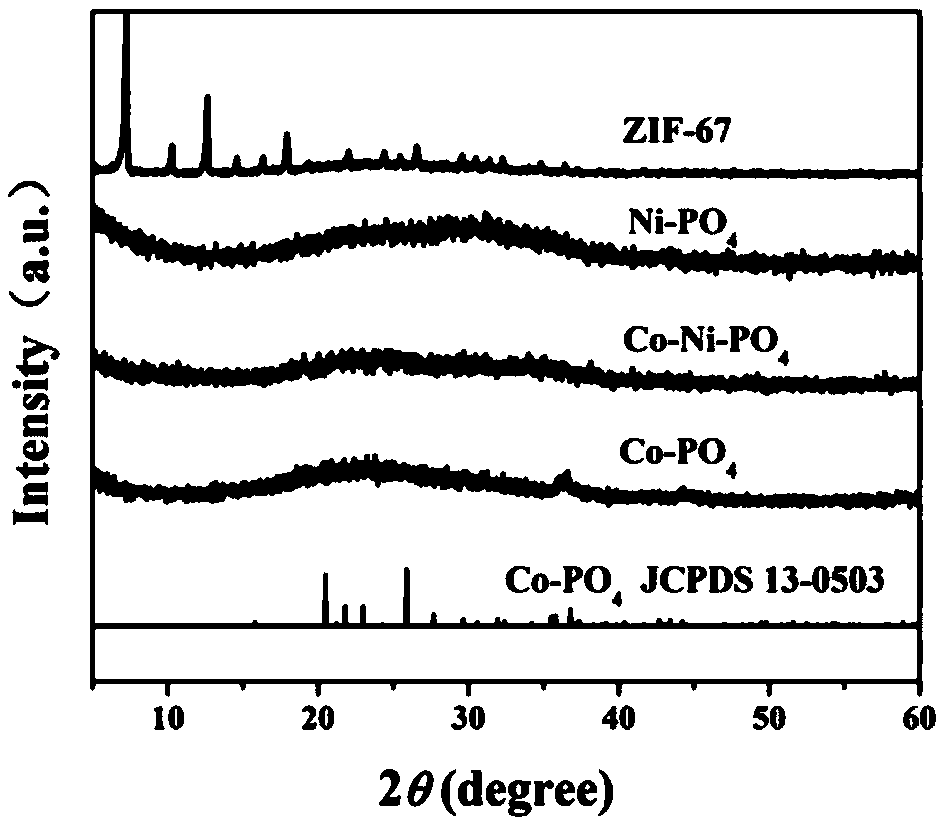

[0055] A method for preparing a bimetallic nano-phosphate based on a metal-organic framework, comprising the following steps:

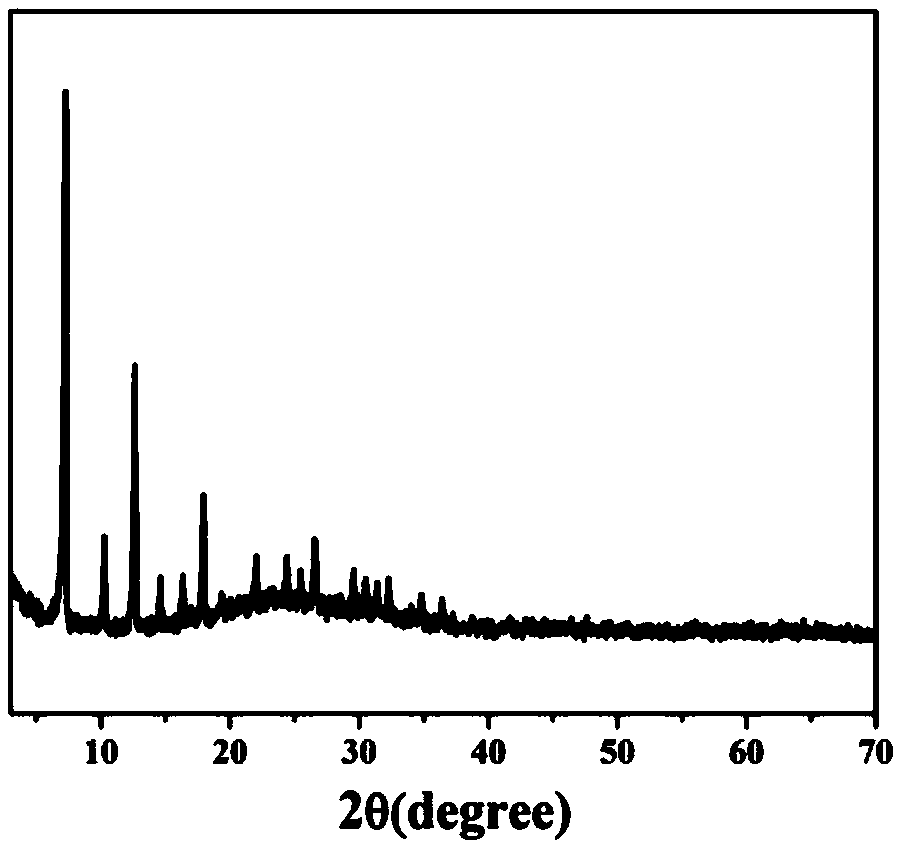

[0056] (1) Preparation of metal-organic framework (ZIF-67): Weigh cobalt nitrate and 2-methylimidazole and dissolve them in 500 mL of organic solvent methanol according to the molar ratio of 1:4, in which 1mol of cobalt nitrate and 2-methylimidazole 4mol, stir to mix evenly, stand at room temperature for 24h, filter the above reaction solution, wash the precipitate with mother liquor, and dry at 70°C to obtain the required crystalline material metal-organic framework ZIF-67;

[0057] (2) Preparation of precursor (ZIF-67-LDH): Weigh 100mg ZIF-67 and dissolve in 160mgNi(NO 3 ) 2 The dehydrated ethanol solution, strong stirring 30min, the stirring speed is 500r / min, can obtain the solution of ZIF-67-LDH;

[0058] (3) The preparation of ZIF-67-CNP: add 80mgNa in the solution gained in step (2) 3 PO 4 The distilled aqueous solution was stirred for 1 ho...

Embodiment 2

[0061] (1) The preparation of ZIF-67 metal-organic framework is the same as that in Example 1.

[0062] (2) The preparation of ZIF-67-LDH is the same as in Example 1.

[0063] (3) The preparation of ZIF-67-CNP: add 80mgNa in the solution gained in step (2) 3 PO 4 The distilled aqueous solution was stirred for 1 hour and then reacted at 25°C for 15 hours. The resulting precipitate was centrifuged, washed three times with deionized water and absolute ethanol, and dried at 70°C for 12 hours to obtain the target product.

[0064] The preparation of the active material electrode is the same as in Example 1.

Embodiment 3

[0066] (1) The preparation of ZIF-67 metal-organic framework is the same as that in Example 1.

[0067] (2) The preparation of ZIF-67-LDH is the same as in Example 1.

[0068] (3) The preparation of ZIF-67-CNP: add 80mgNa in the solution gained in step (2) 3 PO 4 The distilled aqueous solution was stirred for 1 hour and then reacted at 50°C for 15 hours. The resulting precipitate was centrifuged, washed three times with deionized water and absolute ethanol, and dried at 70°C for 12 hours to obtain the target product.

[0069] The preparation of the active material electrode is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com