Method and apparatus for producing hydrogen

a technology of hydrogen production and method, applied in the direction of electrolysis components, electrolysis processes, cells, etc., can solve the problems of large electrical power required for hydrogen production, no electrolyzer or process conditions adapted to these circumstances, and no more than 80% of electric efficiency, etc., to achieve the effect of lowering the oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

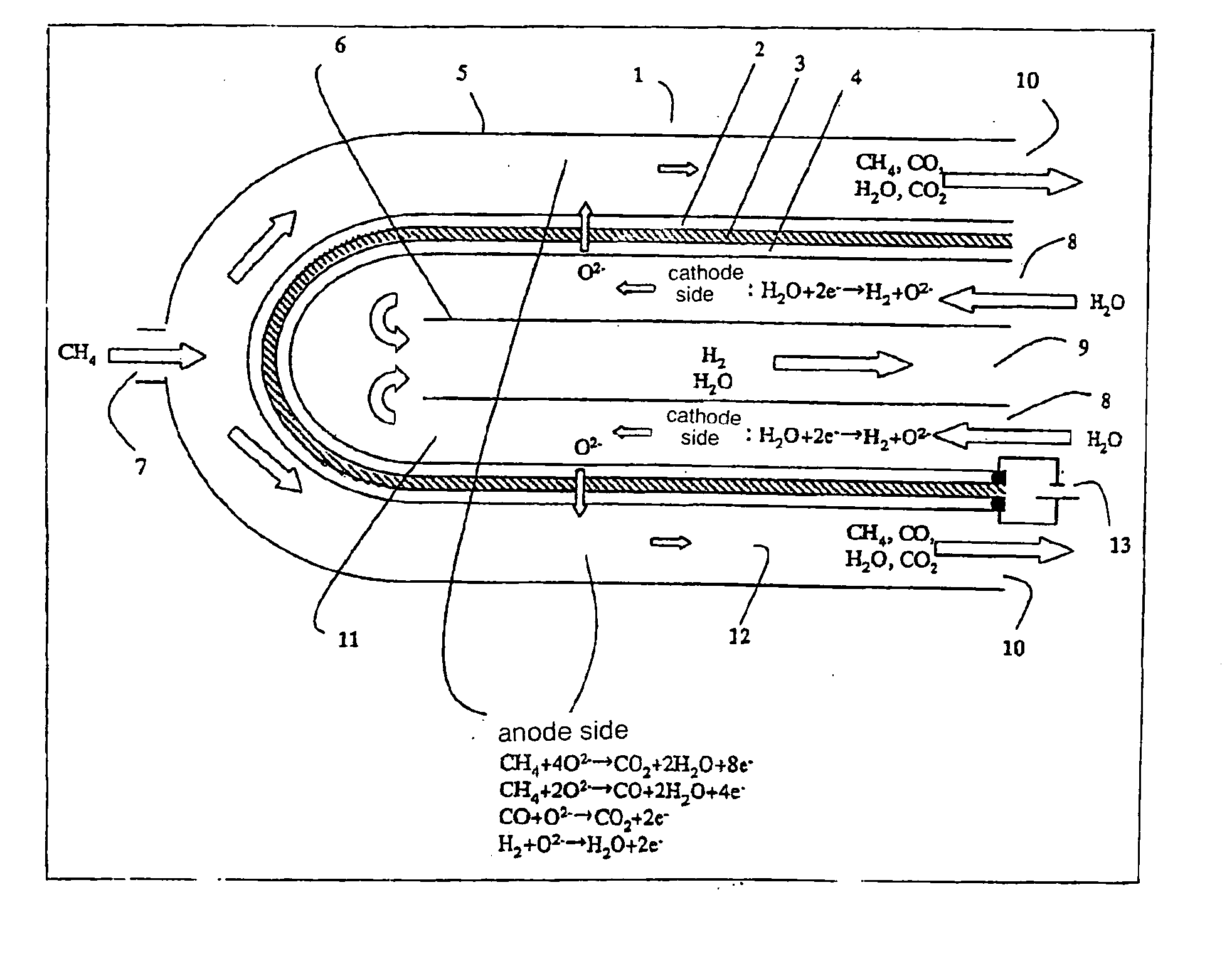

[0051] A test of hydrogen production by high temperature steam electrolysis according to the second embodiment of the present invention was carried out using the high temperature steam electrolytic apparatus shown in FIG. 7. In the high temperature steam electrolytic apparatus 1 shown in FIG. 7, electrodes (anode 2 and cathode 4) are mounted on both sides of a cylindrical solid oxide electrolyte diaphragm 3 that is closed at one end and the electrolyzer 5 is partitioned into an anode side 12 and a cathode side 11. A discharge conduit 6 is placed on the cathode side 11 to discharge the product mixed gas of hydrogen and steam. A gas inlet 7 is formed in the anode side 12 of the electrolyzer for the introduction of hydrocarbon-containing gas. This structure is about the same as that of the cell of a solid oxide fuel cell (SOFC), and the procedure for fabricating it is also almost unchanged from that for an SOFC cell. In the example under consideration, a thin film (film thickness=100 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrolysis voltage | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| electrolysis voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com