Cold punched die and manufacturing method thereof

A mold and cold stamping technology, which is applied in the field of wear-resistant carbide coating composite cold stamping mold and its preparation, can solve the problems of demanding production equipment, low production efficiency, and low bonding strength of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

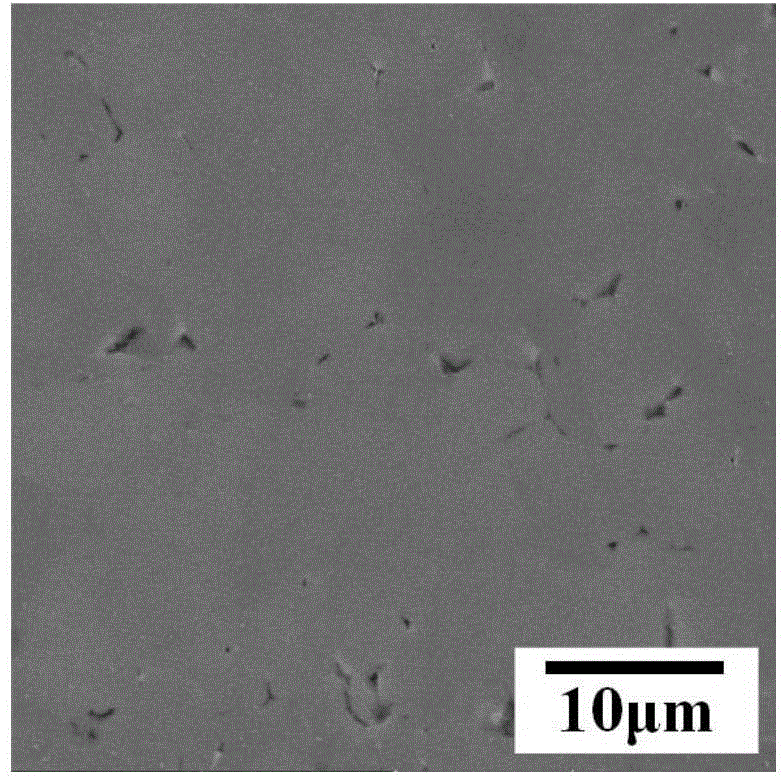

[0073] Embodiment 1: the preparation method of cold stamping die die, comprises the steps:

[0074] 1. First prepare a titanium plate 2, wherein the purity of titanium should be controlled at 99.7%. The titanium plate 2 should be surface treated first, the steps are as follows:

[0075] The first step is pickling, choose 300ml / L hydrochloric acid, and then rinse with running water;

[0076] In the second step of pickling, choose 300ml / L hydrofluoric acid, and then rinse with running water;

[0077] The third step is surface grinding, using 800 mesh Al 2 o 3 Sandpaper and finally ultrasonic cleaning with alcohol. The thickness of the titanium plate 2 is controlled at 1mm.

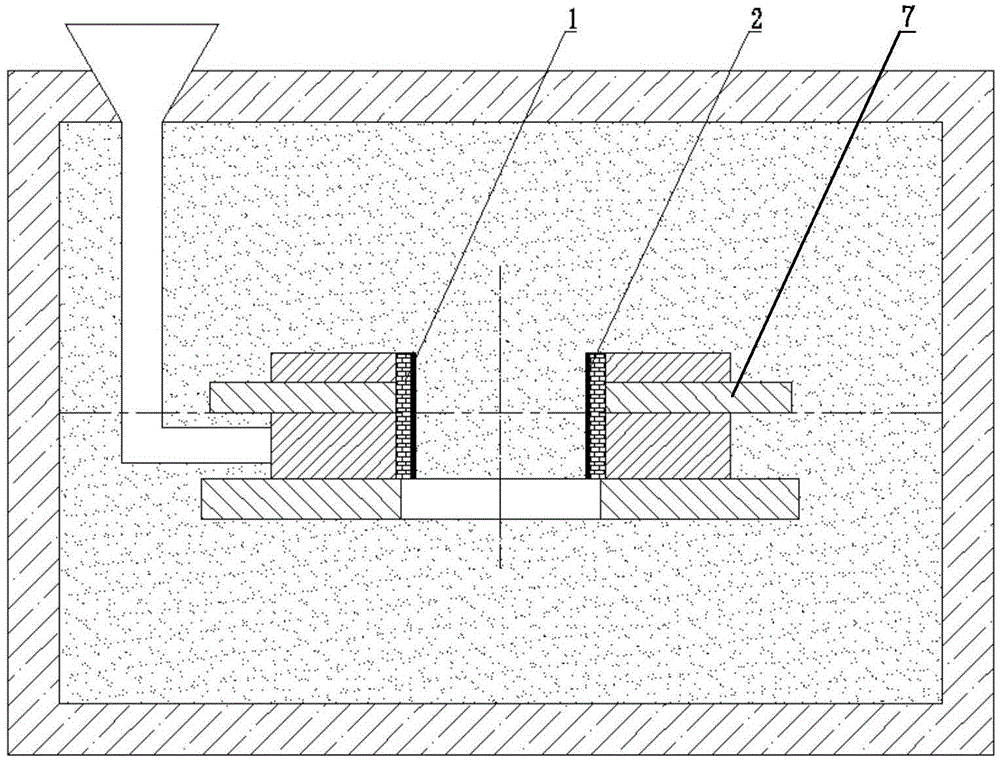

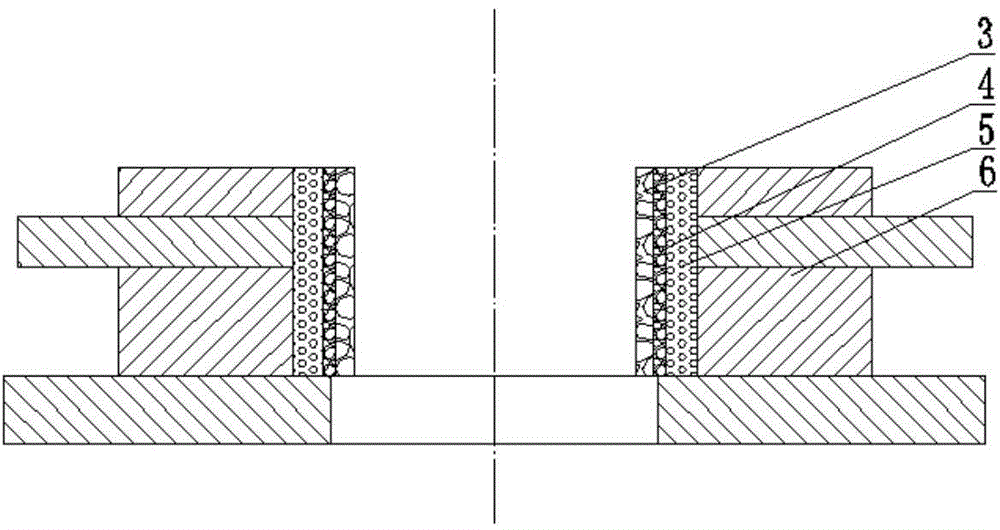

[0078] 2. According to the size of the die of the cold stamping die, use polystyrene foam to make the lost mold of the die of the cold stamping die. surface, according to which the titanium plate 2 is fixed on the cutting edge surface of the concave lost mold 7, and then the graphite paper 1 is fixed o...

Embodiment 2

[0087] Embodiment 2: the preparation method of cold stamping die die, comprises the steps:

[0088] 1. Prepare a titanium plate 2 first, wherein the purity of titanium should be controlled at 99.8%. The titanium plate 2 should be surface treated first, and the steps are as follows:

[0089] The first step is pickling, 60ml / L phosphoric acid, and then rinse with running water;

[0090] The second step is pickling, 200ml / L sulfuric acid, and then rinse with running water;

[0091] The third step is surface grinding, using 1000 mesh Al 2 o 3 Sandpaper and finally ultrasonic cleaning with alcohol. The thickness of the titanium plate 2 is controlled at 1.5mm.

[0092] 2. According to the size of the die of the cold stamping die, use polystyrene foam to make the lost mold of the die of the cold stamping die. surface, according to which the titanium plate 2 is fixed on the cutting edge surface of the concave lost mold 7, and then the graphite paper 1 is fixed on the surface of t...

Embodiment 3

[0101] Embodiment 3: the preparation method of cold stamping die die, comprises the steps:

[0102] 1. Prepare a titanium plate 2 first, wherein the purity of titanium should be controlled at 99.8%. The titanium plate 2 should be surface treated first, and the steps are as follows:

[0103] The first step is pickling, 120ml / L hydrogen peroxide, and then rinse with running water;

[0104] The second step is pickling, 240ml / L hydrogen peroxide, and then rinse with running water;

[0105] The third step is surface grinding, using 1200 mesh Al 2 o 3 Sandpaper and finally ultrasonic cleaning with alcohol. The thickness of the titanium plate 2 is controlled at 2.5 mm.

[0106] 2. According to the size of the die of the cold stamping die, use polystyrene foam to make the lost mold of the die of the cold stamping die. surface, according to which the titanium plate 2 is fixed on the cutting edge surface of the concave lost mold 7, and then the graphite paper 1 is fixed on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com