Composite bipolar plate for proton exchange membrane fuel cell and production method thereof

A proton exchange membrane and fuel cell technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve problems such as low strength, low electrical conductivity, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

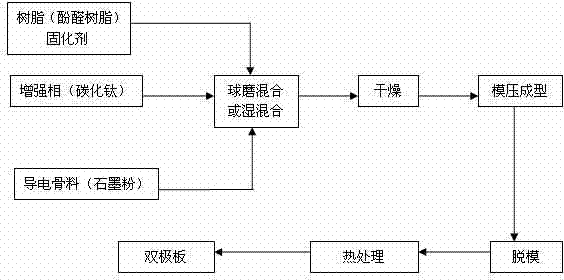

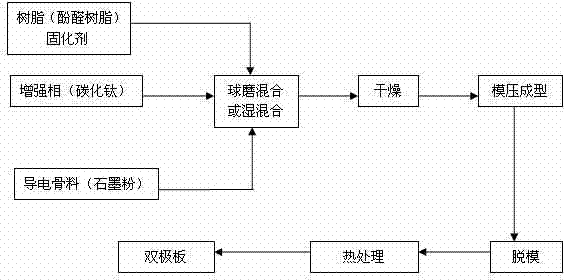

Method used

Image

Examples

Embodiment 1

[0032] 1) 10% by weight of phenolic resin, 10% by weight of titanium carbide and 77% by weight of graphite are dry-mixed by ball milling, and then dried in an oven at 60-100°C for 1-5 hours;

[0033] 2) Take out the dried powder, add 3% by weight curing agent hexamethylenetetramine, put it into the mold cavity, the mold cavity is processed with a flow channel (flow field), so that the flow channel after molding All can be molded at one time; (2) Clamping: Clamp the mold after adding materials, the clamping time is 5s~30s, the clamping pressure is 40 MPa, the molding temperature is 200°C, and the holding time is 5min. ;3) Exhaust: After the mold is closed, the pressure needs to be released and exhausted. The number of exhausts is 1~3 times, and the time for each time is 3s~20s; (5) Demoulding: After the curing is completed, use the push rod to demould .

[0034] 3) After compression molding, clamp the bipolar plate with a clamp and place it in an oven for heat preservation tre...

Embodiment 2

[0038] 1) Mix 5%~20% (example 5%, 12%, 20%) of phenolic resin by weight, 1%~10% (example 1%, 5%, 10%) of titanium carbide by weight and 60%~ Mix 93% (for example 60%, 75%, 93%) of graphite by weight, and then dry it in an oven at 60-100°C (for example, 60°C, 80°C, 100°C) for 1-5 h;

[0039] 2) Take out the dried powder, add 1~10% (eg 1%, 6%, 10%) curing agent by weight, put it into the mold cavity, and the mold cavity is processed with a flow channel (flow field) , so that all the flow channels can be formed at one time after molding; (2) Mold closing: after feeding materials, the mold closing time is 5s~30s, and the mold closing pressure is 5~60 MPa (for example, 5 MPa, 30 MPa, 60 MPa MPa), the molding temperature is 130~220°C (eg 130°C, 180°C, 220°C), and the holding time is 1~15min. ;3) Exhaust: After the mold is closed, the pressure needs to be released and exhausted. The number of exhausts is 1~3 times, and the time for each time is 3s~20s; (5) Demoulding: After the curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com