Manufacturing method of combined refining and modifying agent

A technology for refining modifiers and manufacturing methods, applied in the field of aluminum alloy production, can solve problems affecting the stability of product application performance, unfavorable large-scale production, reduction of solidification speed, etc., to ensure stability, composition stability, and improve purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

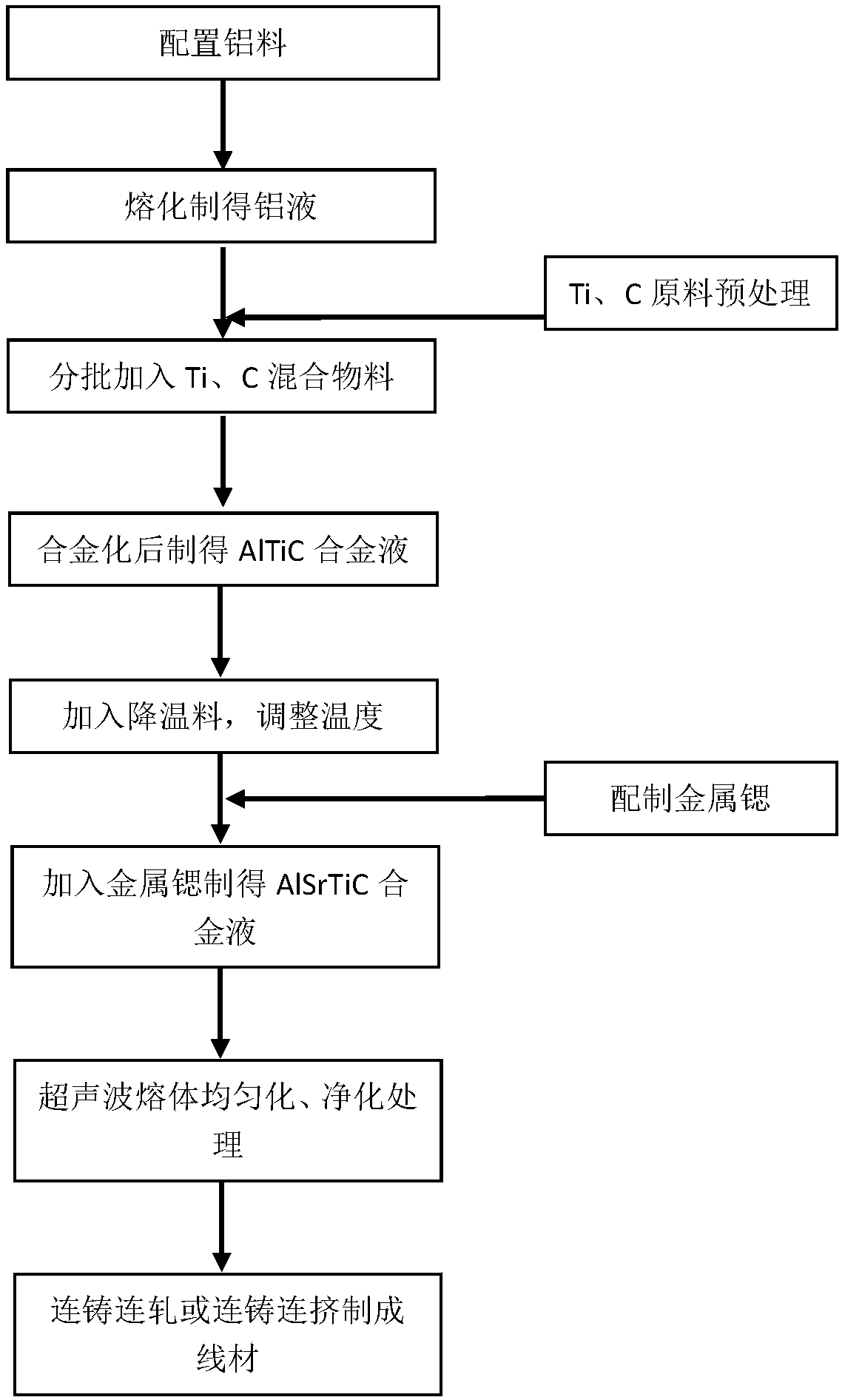

Method used

Image

Examples

Embodiment 1

[0043] Step A, preparation of aluminum raw materials:

[0044] According to the GB / T 1196-2008 standard, select the grade Al99.70 b Aluminum ingots for remelting, where Si≤0.08%, Fe≤0.12%. Choose the aluminum material according to the target Al-Sr10-Ti5-C0.2 master alloy composition that needs to make; Described aluminum material can be the industrial pure aluminum ingot or aluminum block that the mass percent purity is 99.7%; Reserve ratio is about Use aluminum ingots for 30% cooling.

[0045] Step B, preparing titanium-carbon mixed raw materials:

[0046] Select metallic titanium and graphite powder as raw materials, mix them evenly, weigh 250±50g each, wrap them in aluminum foil and keep them for later use.

[0047] Step C, smelting molten aluminum:

[0048] Add the aluminum material prepared in step A into the electric furnace; and raise the temperature to 770±10 degrees at a heating rate of 5 degrees per minute, and melt it into molten aluminum in the electric furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com