Preparation method of two-dimensional transition metal carbide or nitride

A metal carbide and transition metal technology, applied in the field of preparation of two-dimensional transition metal carbides or nitrides, can solve problems such as the inability to obtain single-layer MXene nanosheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Put Ti 2 AlC (0.1g), KOH solid (3.5g) and water (135ml) were stirred evenly, wherein, H 2 O / KOH molar ratio=120;

[0023] 2. Put the ground mixture in a hydrothermal kettle and continue to react at 200°C for 10 hours;

[0024] 3. Wash the obtained mixture with deionized water to obtain a monolayer dispersed MXene colloidal solution.

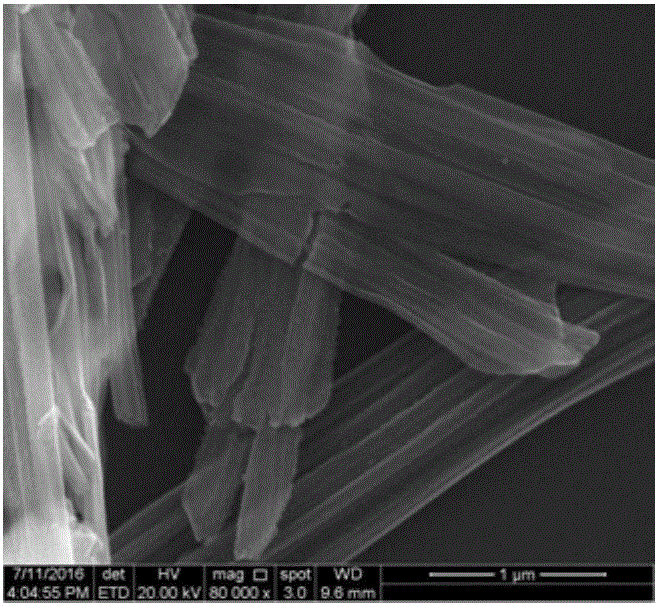

[0025] MXene in the MXene colloidal solution (Ti 3 C 2 ) Scanning electron micrographs of nanosheets such as figure 1 As shown, it can be seen that, compared with the loosely packed structure of the accordion after HF treatment, the sheet of the material obtained according to this embodiment is transparent, indicating that the MXene sheet obtained by this method is thinner and better than the HF treatment method.

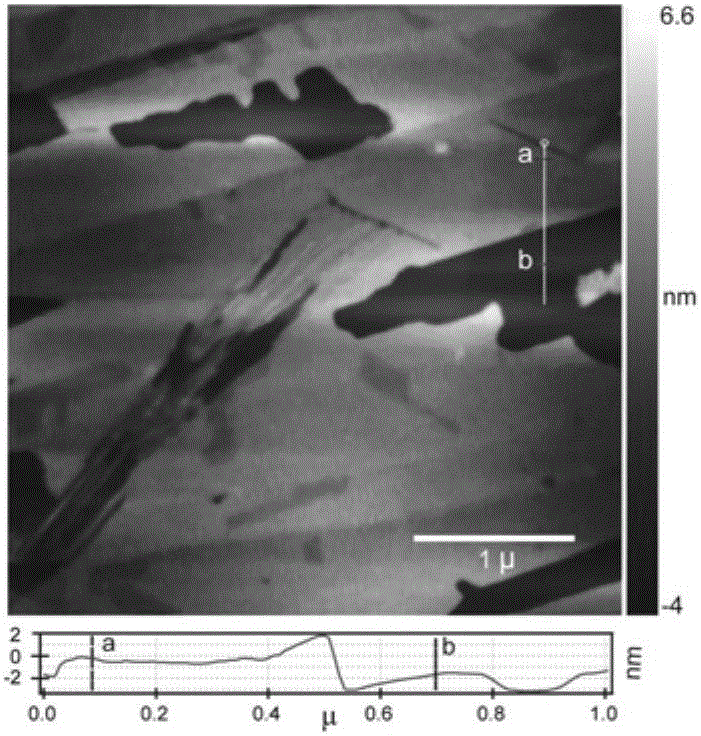

[0026] MXene in the MXene colloidal solution (Ti 3 C 2 ) atomic force microscope (AFM) photo of nanosheets as figure 2 As shown, it can be seen that the thickness of the sheet is about 1.2 nanometers, which is less t...

Embodiment 2

[0028] 1. Put V 2 AlC (0.1g) and KOH solid (0.35g) are ground in the air evenly;

[0029] 2. Put the ground mixture in a hydrothermal kettle and continue to react at 180°C for 24 hours;

[0030] 3. Wash the obtained mixture with deionized water to obtain a monolayer dispersed MXene colloidal solution.

Embodiment 3

[0032] 1. Add Nb 2 AlC (0.1g) and KOH solid (3.5g) are ground evenly;

[0033] 2. Put the ground mixture in a hydrothermal kettle and continue to react at 180°C for 24 hours;

[0034] 3. Wash the obtained mixture with deionized water to obtain a monolayer dispersed MXene colloidal solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com