Carbide crystal material with two-dimensional lamellar structure and preparation method thereof

A technology of two-dimensional sheet and crystal materials, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and crystal growth, and can solve the problems of few studies and reports on two-dimensional transition metal carbides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

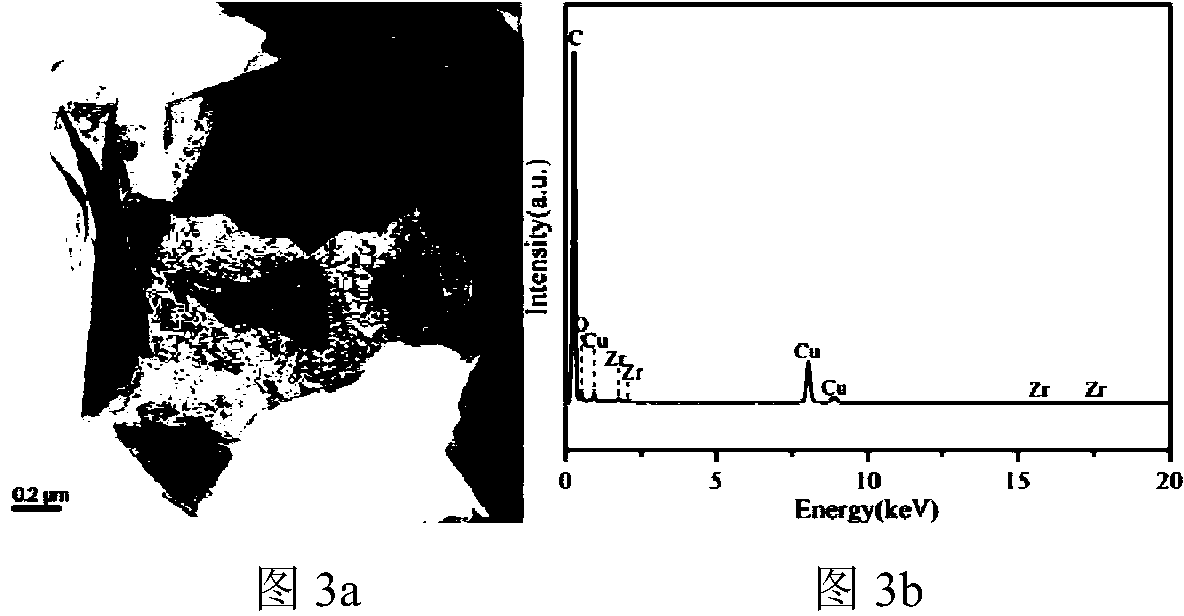

[0038] In this embodiment, the carbide crystal material having a two-dimensional sheet structure is a ZrC nanosheet, and in the ZrC nanosheet, the atomic ratio of the Zr element to the C element is less than or equal to 1.

[0039] The preparation steps of this ZrC nanosheet are as follows:

[0040] (1) with Zr 3 Al 3 C 5 Ceramic materials as precursor materials;

[0041] The Zr 3 Al 3 C 5 The preparation method of the ceramic material is as described in the literature (Zhou, J. et al. J. Am. Ceram. Soc., 2014, 97, 1296.);

[0042] (2) Crushing the precursor material, passing through a 300-mesh sieve after grinding, to obtain a precursor powder with uniform particle size distribution;

[0043] (3) Select a hydrofluoric acid aqueous solution with a concentration of 50wt.% as the corrosive agent, slowly add 1 g of the precursor powder in an ice-water bath to a plastic bottle containing 10 mL of the corrosive agent, mix it uniformly and let it stand for 72 hours, and Stir...

Embodiment 2

[0055] In this embodiment, as in Embodiment 1, the carbide crystal material having a two-dimensional sheet structure is ZrC nanosheet, and in the ZrC nanosheet, the atomic ratio of Zr element to C element is less than or equal to 1.

[0056] The preparation method of the ZrC nanosheets is basically the same as in Example 1, except that in step (3), a hydrofluoric acid aqueous solution with a concentration of 25 wt.% is selected as the etchant.

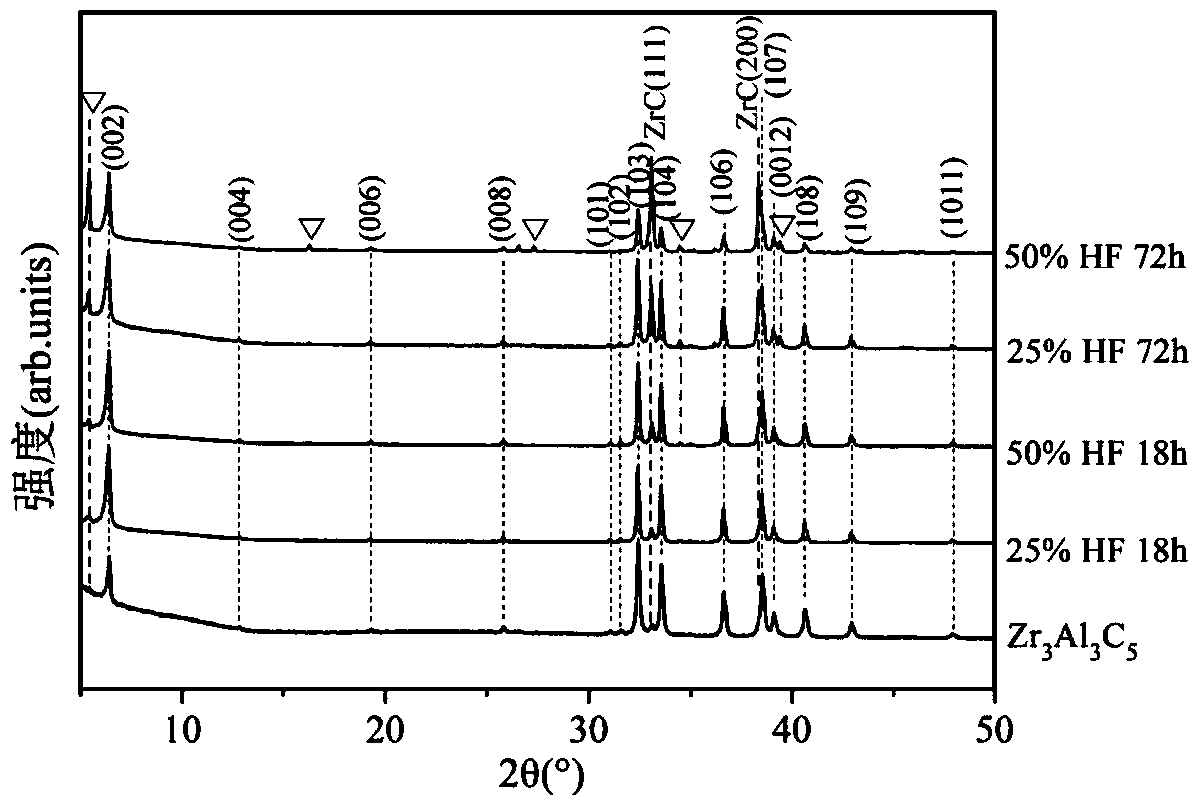

[0057] Same as Example 1, utilize X-ray diffraction spectrum (XRD) to detect respectively through step (3) before corroding, in step (3) after mixing with etchant 18h, and in step (3) after mixing with etchant 72h powder Changes in phase and crystal structure of the body; Utilize scanning electron microscope (SEM) to observe before step (3) corrosion, after mixing with etchant in step (3) for 18h, and after mixing with etchant in step (3) for 72h powder morphology changes.

[0058] XRD test results such as figure 1 Shown in, this str...

Embodiment 3

[0062] In this embodiment, the carbide crystal material having a two-dimensional sheet structure is HfC nanosheet, and the atomic ratio of Hf element to C element in the HfC nanosheet is less than or equal to 1.

[0063] The preparation steps of this HfC nanosheet are as follows:

[0064] (1) The chemical molecular formula is Hf 2 [Al 1-x (Si) x ] 4 C 5 (The ceramic material of (as precursor material, wherein x=0,0.02,0.05,0.1;

[0065] The Hf 2 [Al 1-x (Si) x ] 4 C 5 The preparation method of ceramics is as described in the literature (Zhou, J. et al. J. Am. Ceram. Soc., 2014, 97, 1296.), where the elemental components and sintering temperature are shown in Table 1 below.

[0066] Table 1: Hf 2 [Al 1-x (Si) x ] 4 C 5 Raw material ratio and sintering temperature (x=0, 0.02, 0.05, 0.1)

[0067]

[0068] (2) Crushing the precursor material, passing through a 300-mesh sieve after grinding, to obtain a precursor powder with uniform particle size distribution;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com