Preparation method of carbon onion loaded transition metal carbide nano composite

A technology of nanocomposites and transition metals, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve the effects of simple preparation process, low energy consumption, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Weigh 2.5 grams of nitrophenol or nitrotoluene, 0.45 grams of cyclohexane or methylcyclohexane and 0.08 grams of ammonium molybdate or 0.12 grams of molybdenum chloride or 0.2 grams of molybdenum nitrate, fully grind in a mortar, and mix well Finally, put it into the high-pressure reactor and tighten the lid of the kettle. Program the temperature from room temperature to 350°C at a rate of 20°C / min to stop heating. The pressure in the reaction kettle is increased to 20-40 MPa. After the pressure in the reaction kettle decreases and the kettle body cools down naturally, the gas product is released and the solid product is collected. The collected sample weighs about 0.2-0.3 grams.

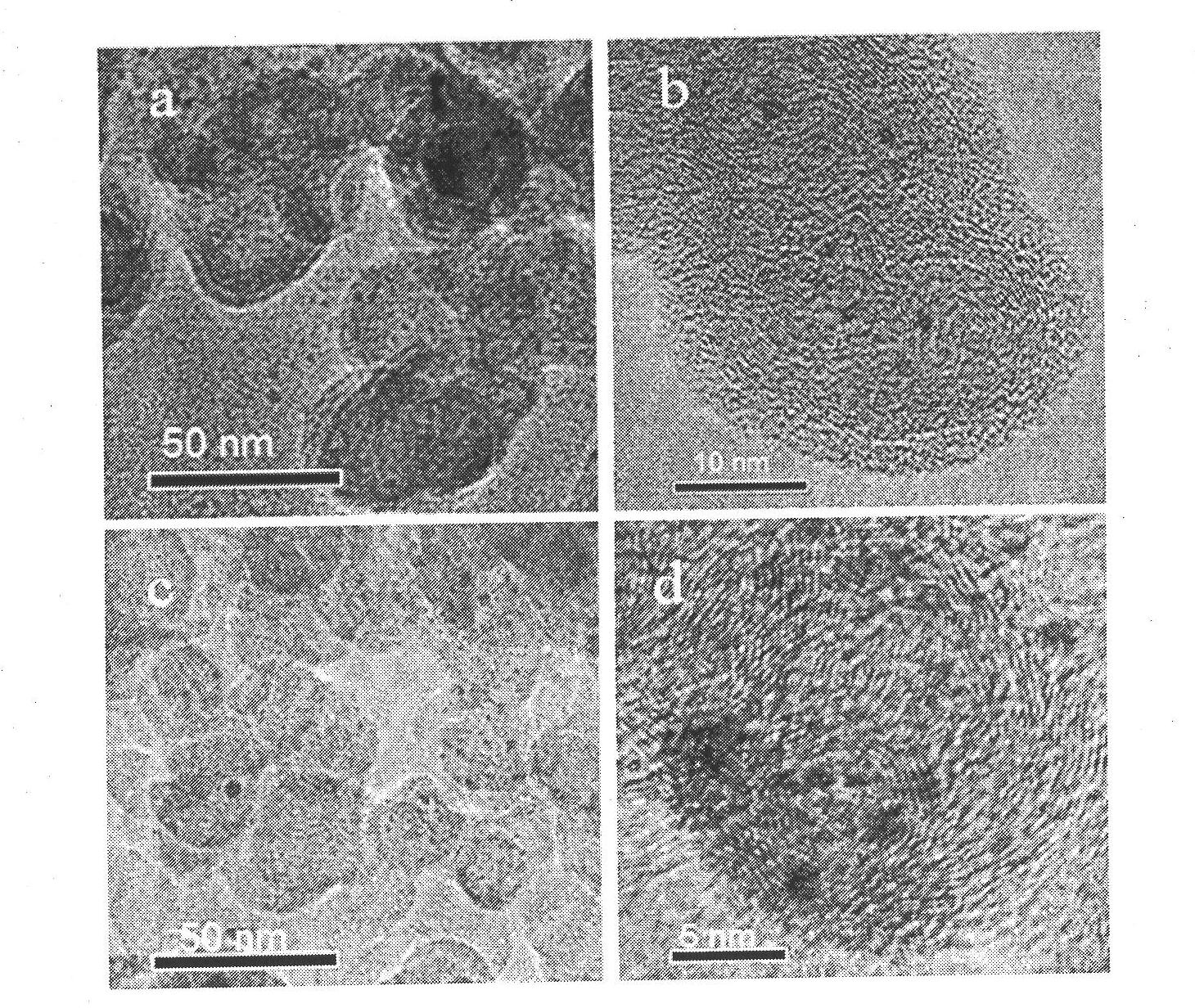

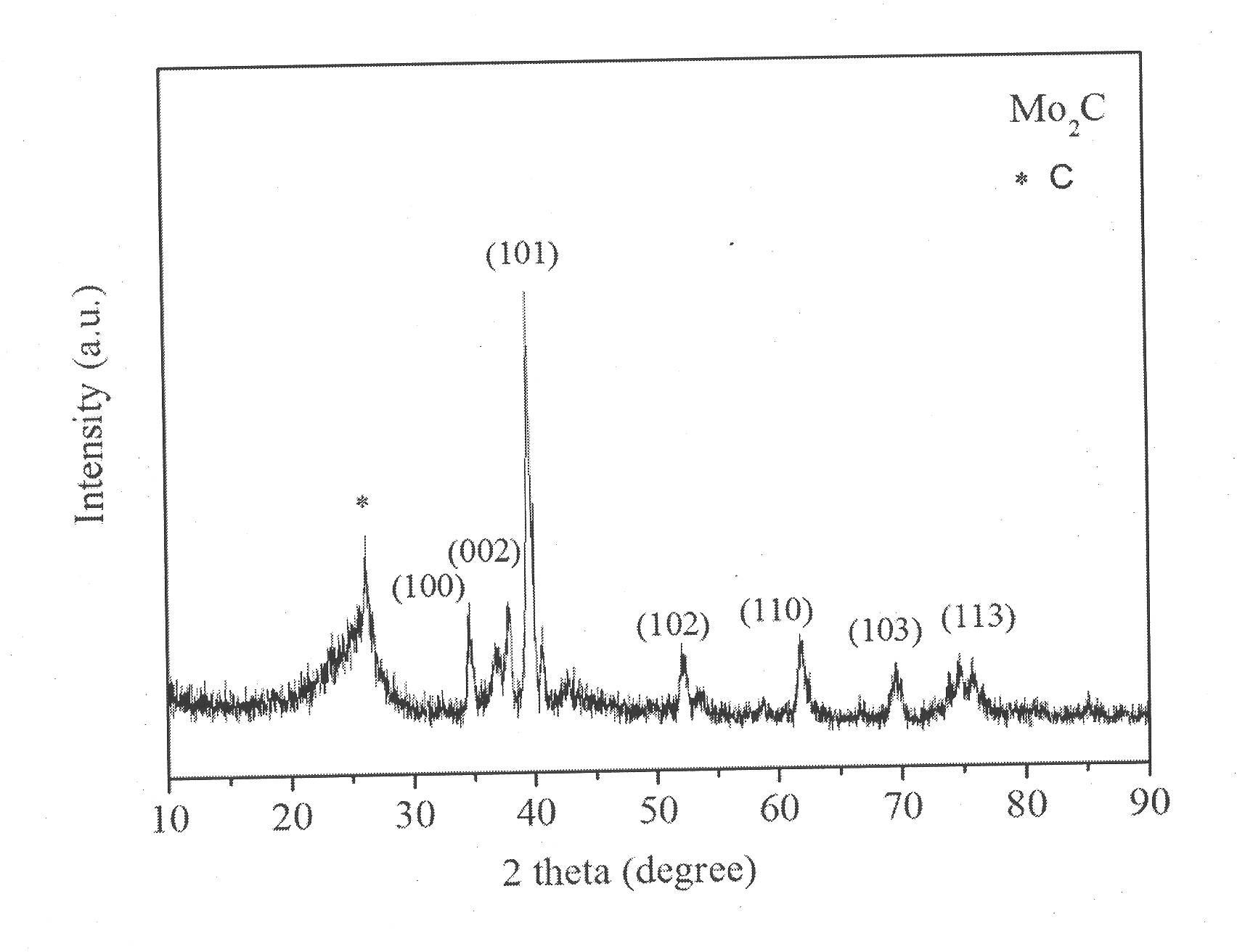

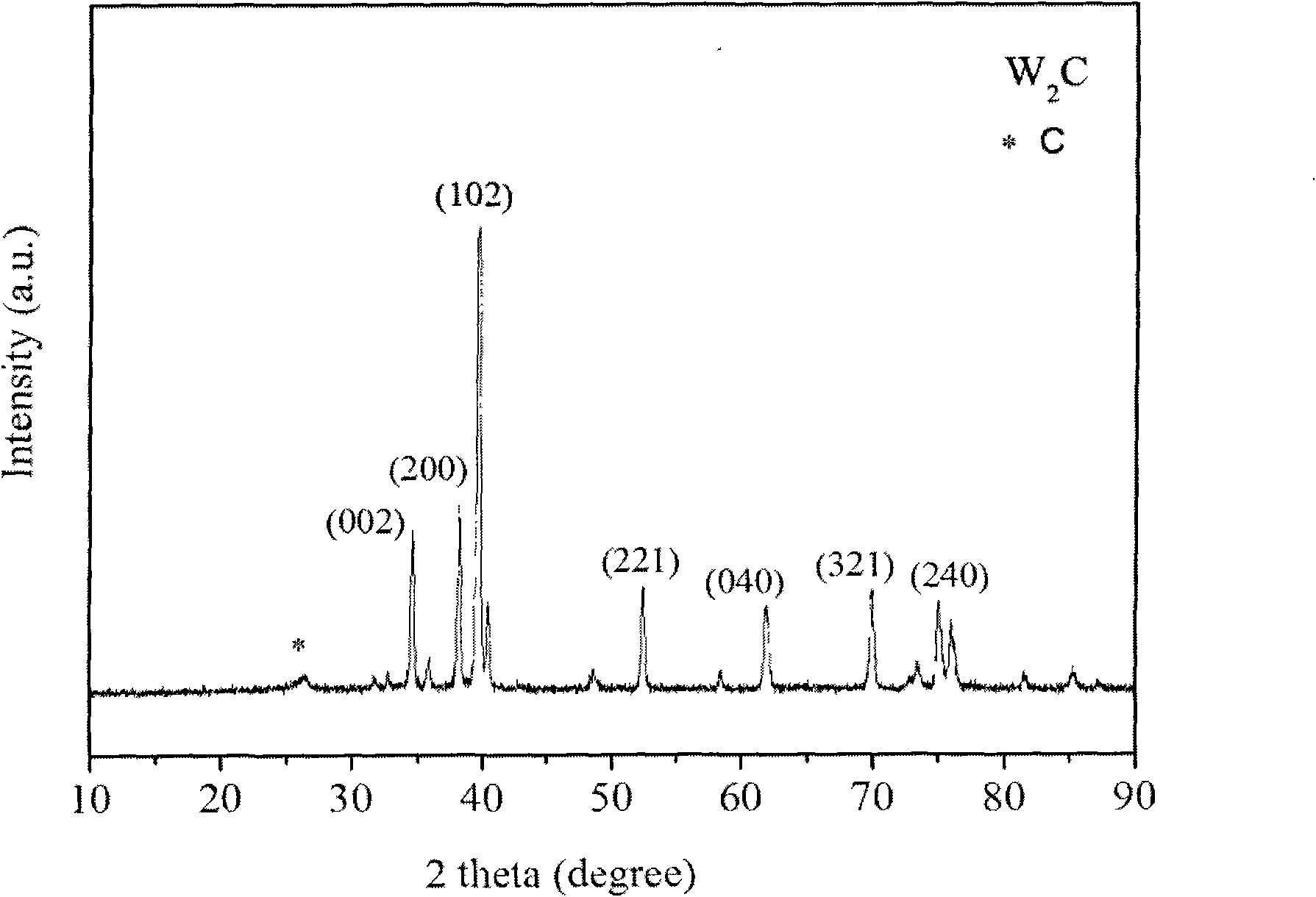

[0016] Characteristic analysis of the sample prepared by the method of the invention shows that the sample is a nanocomposite of carbon and transition metal molybdenum carbide. Directly take a small amount of nanocomposites, disperse them in absolute ethanol and ultrasonically for 15min, dro...

specific Embodiment approach 2

[0017] Weigh 2.5 grams of nitrophenol or nitrotoluene, 0.45 grams of cyclohexane or methylcyclohexane and 0.13 grams of ammonium molybdate or 0.2 grams of molybdenum chloride or 0.32 grams of molybdenum nitrate, fully grind in a mortar, and mix well Finally, put it into the high-pressure reactor and tighten the lid of the kettle. Program the temperature from room temperature to 350°C at a rate of 20°C / min to stop heating. The pressure in the reactor is increased to 20-40 MPa. After the pressure in the reactor decreases and the reactor body cools down naturally, the gaseous product is released and the solid product is collected. The obtained sample weighs about 0.2-0.3 grams. Characterized by high-resolution transmission electron microscopy and X-ray diffractometer, the sample is a nanocomposite of molybdenum carbide supported on onion carbon. The particle size distribution range of onion carbon is 20-30nm. The metal molybdenum carbide dispersed on the surface of onion carbon h...

specific Embodiment approach 3

[0018] Weigh 2.5 grams of nitrophenol or nitrotoluene, 0.45 grams of cyclohexane or methylcyclohexane and 0.18 grams of ammonium molybdate or 0.28 grams of molybdenum chloride or 0.45 grams of molybdenum nitrate, fully grind in a mortar, and mix well Finally, put it into the high-pressure reactor and tighten the lid of the kettle. Program the temperature from room temperature to 350°C at a rate of 20°C / min to stop heating. The pressure in the reactor is increased to 20-40 MPa. After the pressure in the reactor decreases and the reactor body cools down naturally, the gaseous product is released and the solid product is collected. The obtained sample weighs about 0.2-0.3 grams. High-resolution transmission electron microscope and X-ray diffractometer are used to characterize, the sample is the nanocomposite of molybdenum carbide supported on onion carbon, and the particle size distribution range of onion carbon is 30-40nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution range | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size distribution range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com