Preparation method of Ti2CMXene-based battery electrode material

A battery electrode and film material technology, applied in the field of material chemistry, can solve the problems of unsatisfactory sodium ion free intercalation, inability to apply sodium ion batteries, poor cycle stability, etc., to achieve good cycle stability, low ion diffusion resistance, good Effect of Magnification Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

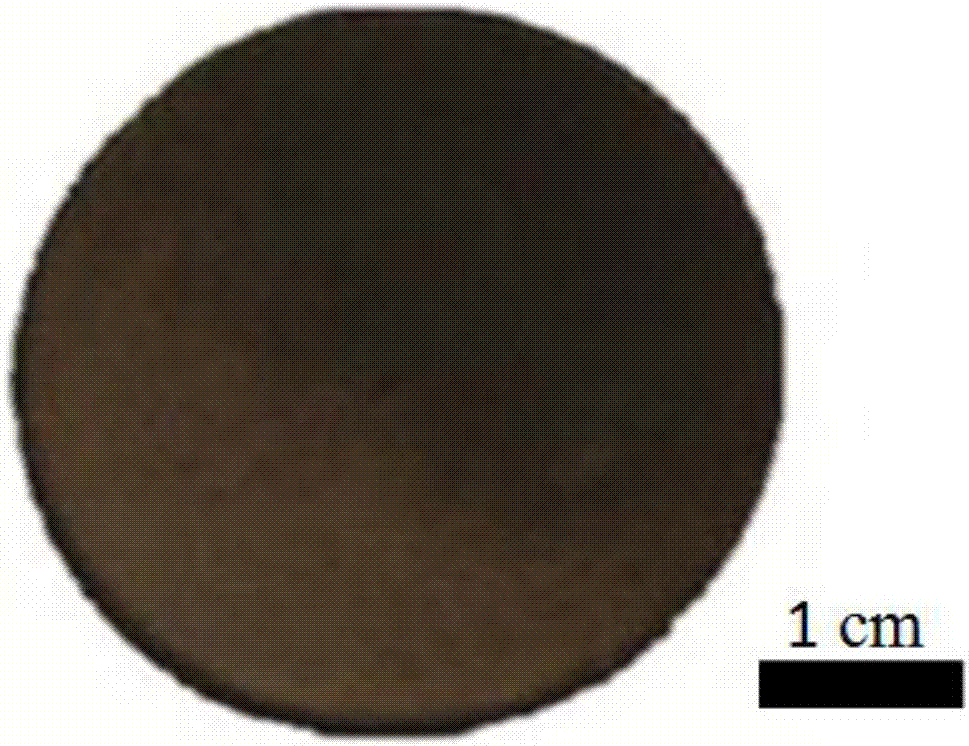

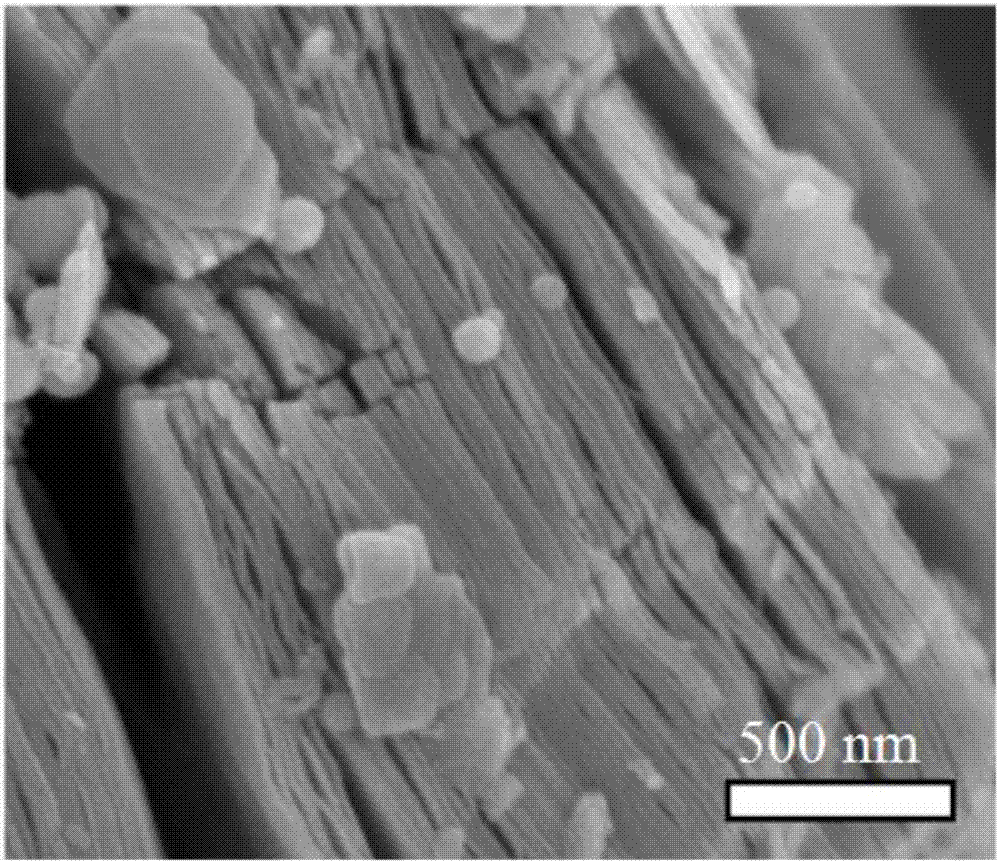

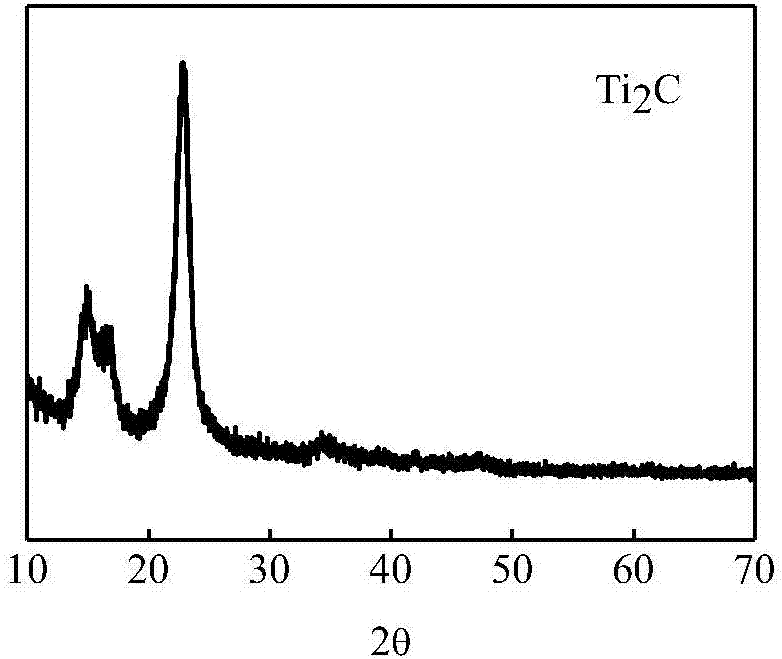

[0016] This embodiment provides a Ti-based 2 The preparation method of the battery electrode material of C MXene, the preparation method of this embodiment is by making Ti 2 C MXene undergoes intercalation and exfoliation to obtain Ti 2 CMXene thin film material, Ti 2 C MXene thin film material, after intercalation and stripping, the interlayer spacing becomes larger, and the material has high specific surface area, good electrical conductivity, good cycle stability and rate performance, and at the same time, after MXene material is intercalated, the material has low ion Diffusion resistance, low open circuit voltage and high storage capacity. It is very suitable for electrode materials used in energy storage devices such as lithium batteries and supercapacitors.

[0017] Its preparation method is as follows:

[0018] First step S1: carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com