Method for preparing titanium carbide nanometer particles and composite materials thereof by direct current arc method

A DC arc method and nanoparticle technology, applied in the direction of titanium carbide, carbide, etc., can solve the problems of low output, long reaction time, quality limitation, etc., and achieve the effect of high product purity and uniform particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take micron-sized titanium powder (purity 99.7%), press it into a block under a pressure of 25MPa as the anode, and graphite rod as the cathode, and adjust the distance between the two electrodes to about 30mm. Vacuum the reaction chamber to about 10 -2 Pa, filled with methane and hydrogen at a ratio of 1:3 to reach 1x10 4 Pa and 3x10 4 Pa. Turn on the cooling water system, turn on the power and start the arc, adjust the current and the distance between the two electrodes and stabilize the arc, evaporate the bulk target, form atomic clusters and gather them into nanoparticles and deposit them on the wall of the reaction chamber, and collect the powder through passivation process.

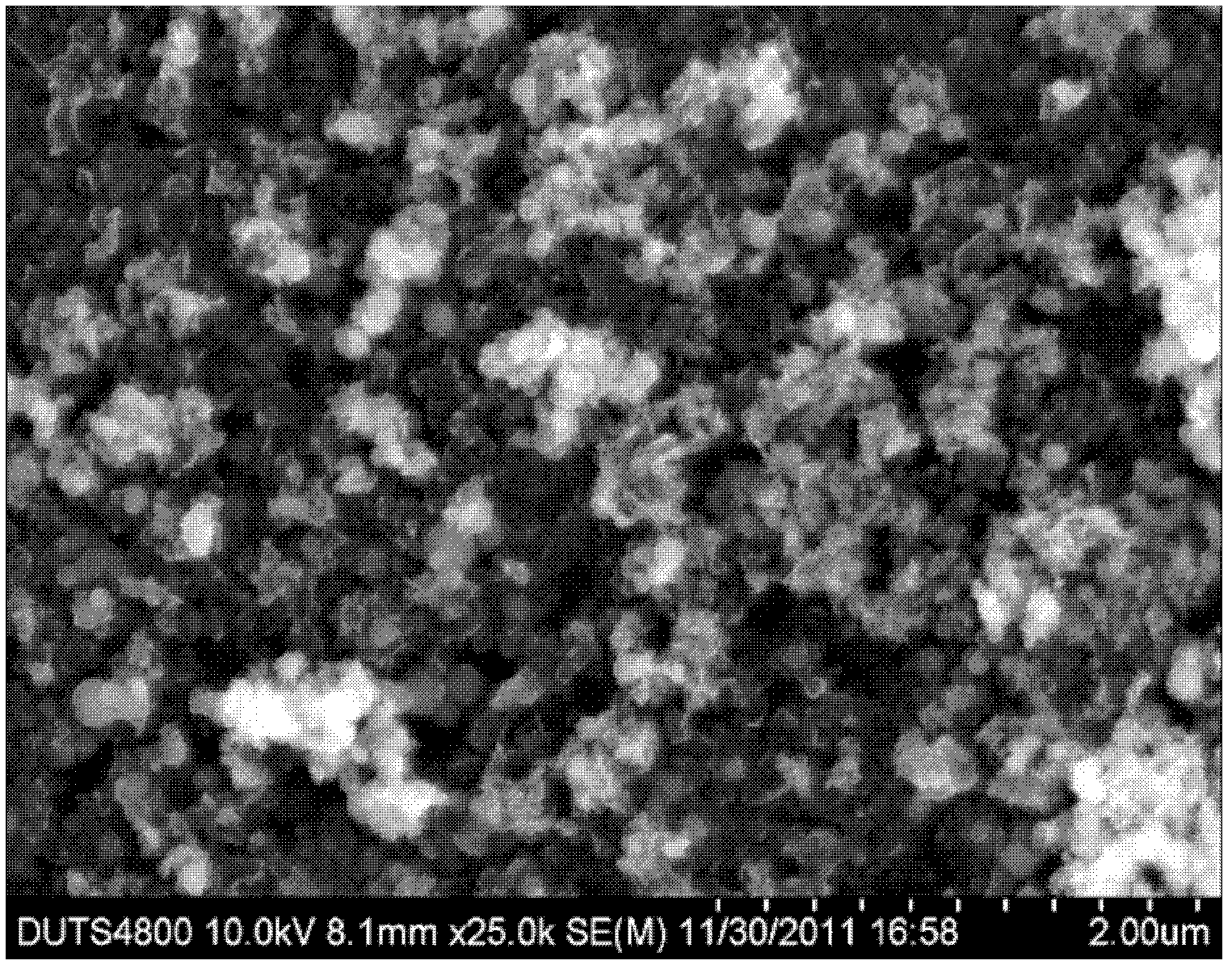

[0025] The SEM image of the titanium carbide nanoparticles obtained in embodiment one is as follows figure 1 As shown, it shows that the particle distribution is uniform;

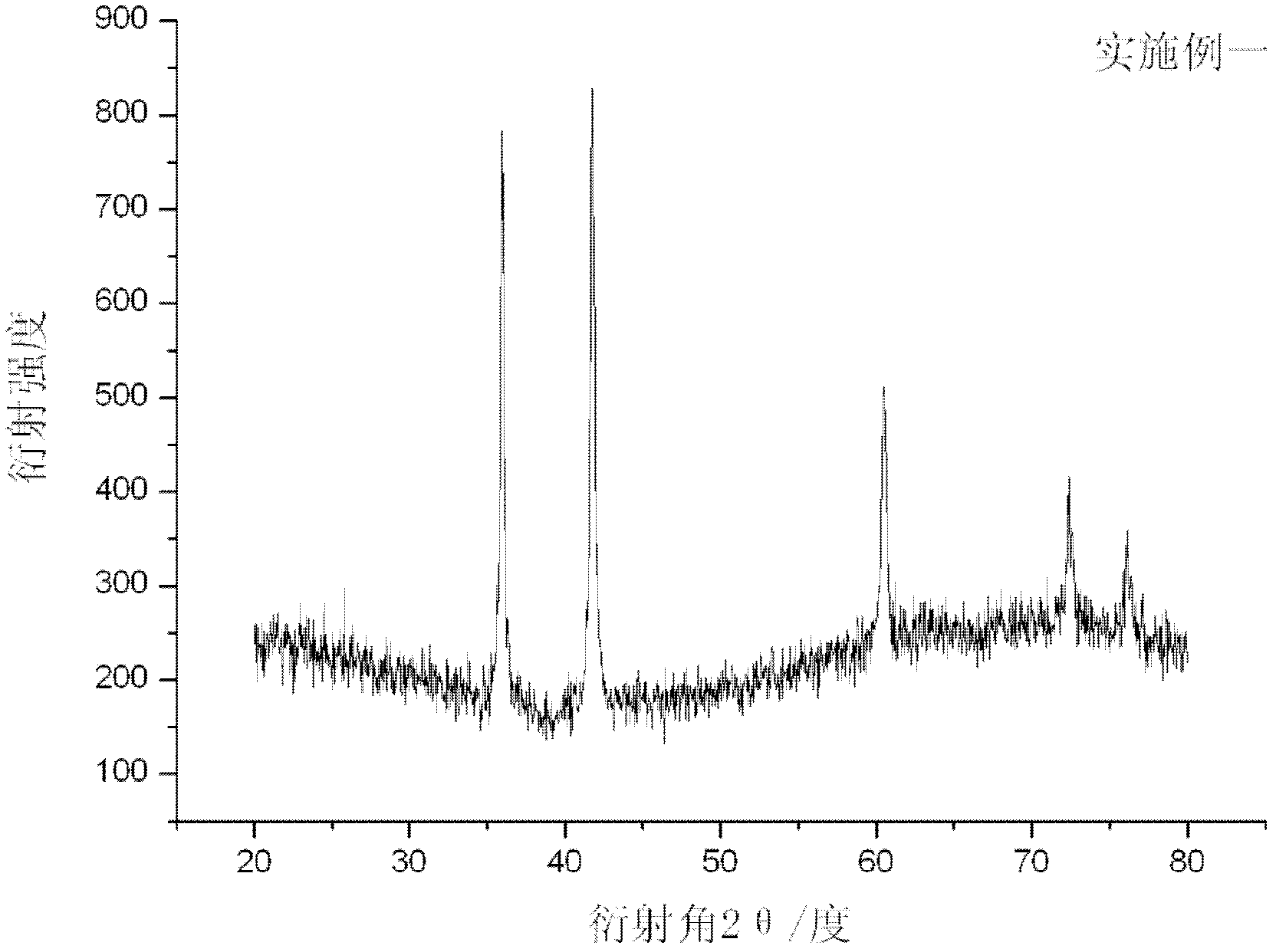

[0026] The obtained titanium carbide nanoparticle XRD collection of patterns of embodiment one is as follows figur...

Embodiment 2

[0028] The implementation steps are basically the same as in Example 1, except that the type and ratio of the mixed atmosphere are different, and 1:2 methane and argon are charged to reach 1×10 respectively. 4 Pa and argon.

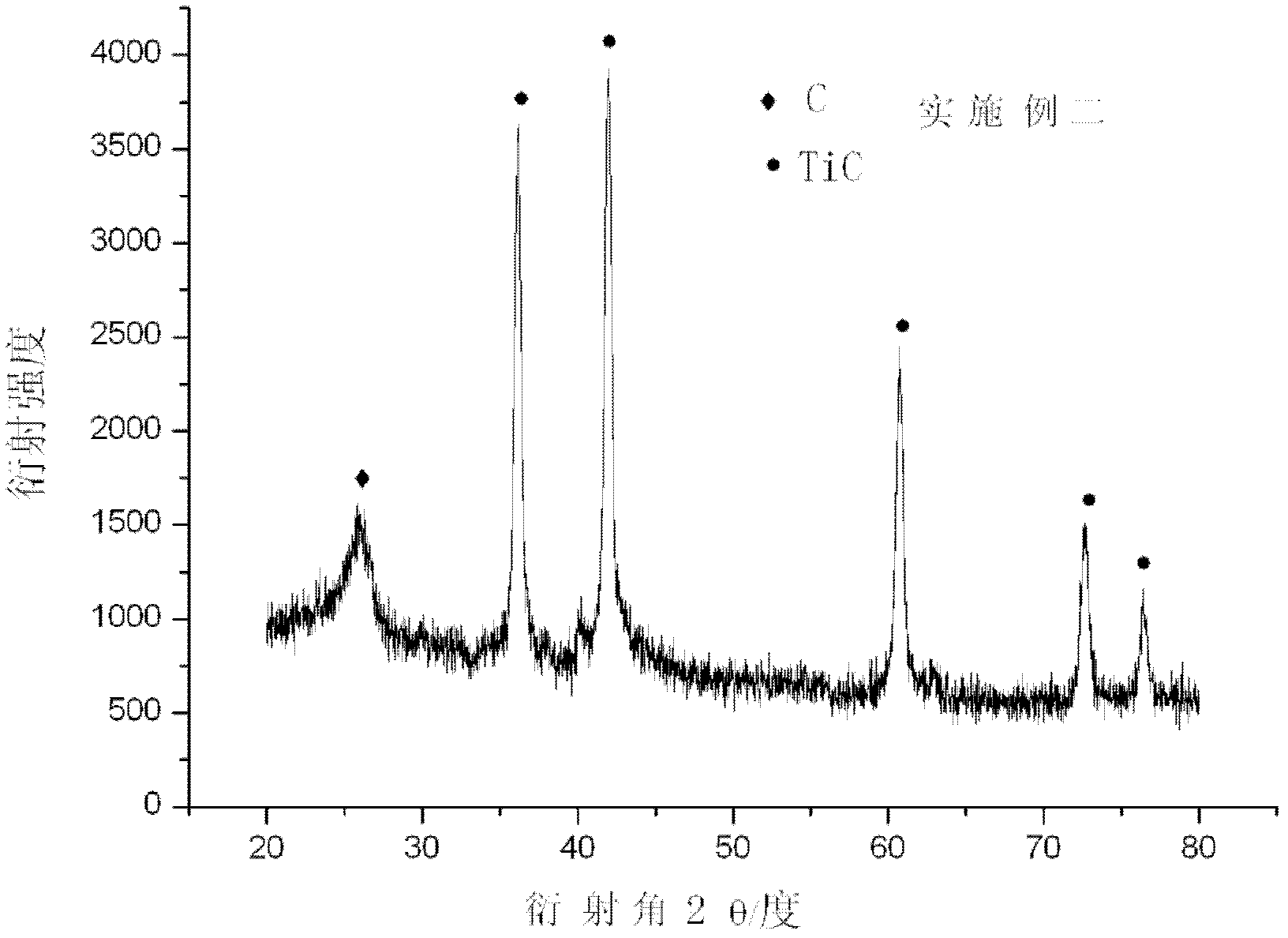

[0029] The XRD pattern of the titanium carbide nanocomposite particles obtained in Example 2 is shown in Figure 4, which indicates that there is also a graphite phase in the product besides the titanium carbide phase, forming a nanocomposite structure of carbon-coated titanium carbide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com