Two-dimensional material quantum sheet and preparation method thereof

A two-dimensional material and quantum sheet technology, applied in the field of two-dimensional material quantum sheet and its preparation, can solve problems such as poor versatility, complex preparation process, and difficulty in realizing large-scale production, and achieves low defects, wide sources, and large-scale production. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Mix 1 g of graphite raw material with an average size of about 500 μm, 1 g of silicon dioxide with an average size of 400 nm, and 10 g of agate balls with a diameter of 0.5 mm, and ball mill for 0.5 h.

[0050] (2) Separate the agate balls, add N-methylpyrrolidone (NMP) to prepare a 1 mg / mL dispersion, and then sonicate for 120 h with an ultrasonic power of 50 W.

[0051] (3) The sample after ultrasound is first vacuum filtered, passed through a filter membrane with a pore size of 0.02 μm, and then the filtrate is centrifuged. The centrifugal speed is 500r / min, and the centrifugation time is 120min, that is, the graphene quantum sheet NMP dispersion is obtained. liquid.

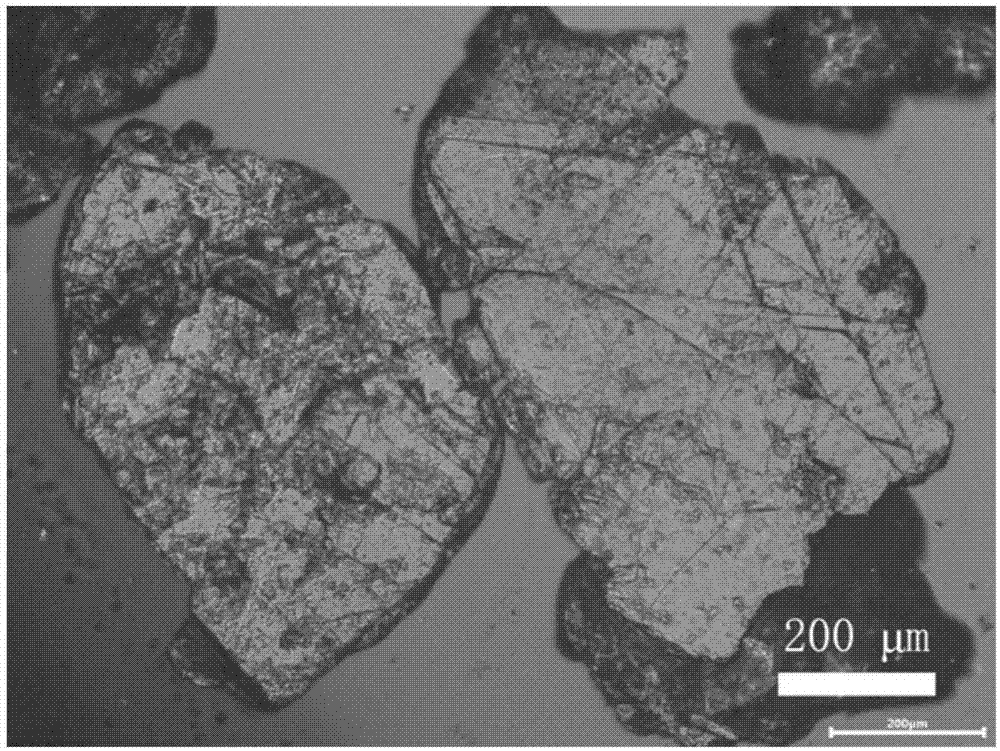

[0052] figure 1 Be the optical micrograph of graphite raw material in embodiment 1. Depend on figure 1 It can be seen that its size is about 500 μm.

[0053] figure 2 It is the appearance photo of the graphene quantum sheet NMP dispersion liquid prepared in embodiment 1. Depend on figure 2...

Embodiment 2

[0056] (1) 0.1 g of MoS with an average size of 2 μm 2 Raw materials, 10g of aluminum oxide with an average size of 100nm and 100g of stainless steel balls with a diameter of 20mm were mixed, and ball milled for 120h.

[0057] (2) Separate the stainless steel balls, add NMP to prepare a 50mg / mL dispersion, and then sonicate for 0.5h with an ultrasonic power of 1000W.

[0058] (3) The sample after ultrasonication is first vacuum filtered, passed through a filter membrane with a pore size of 0.02 μm, and then the filtrate is centrifuged at a speed of 10000r / min, and the centrifugation time is 1min, to obtain MoS 2 NMP dispersion of quantum flakes.

Embodiment 3

[0060] (1) Mix 0.01 g of hexagonal boron nitride raw material with an average size of 100 μm, 0.1 g of titanium dioxide with an average size of 500 nm, and 10 g of zirconia balls with a diameter of 6 mm, and ball mill for 20 h.

[0061] (2) The zirconia balls were then separated, and isopropanol was added to form a 10 mg / mL dispersion, which was then sonicated for 5 hours at an ultrasonic power of 200W.

[0062] (3) The sample after ultrasonication is first vacuum filtered, passed through a filter membrane with a pore size of 0.02 μm, and then the filtrate is centrifuged at a speed of 5000r / min, and the centrifugation time is 20min, and the hexagonal boron nitride quantum chip is obtained isopropanol dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com