Method for stabilizing nanometer black phosphorus

A nano and black phosphorus technology, applied in chemical instruments and methods, phosphorus, phosphorus compounds, etc., can solve the problem that nano black phosphorus is easy to be oxidized, and achieve the effect of solving structural instability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

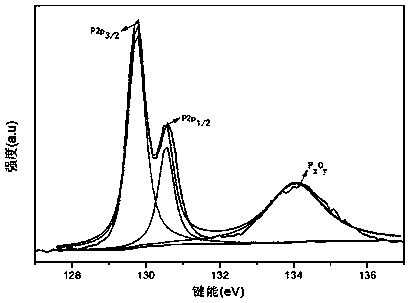

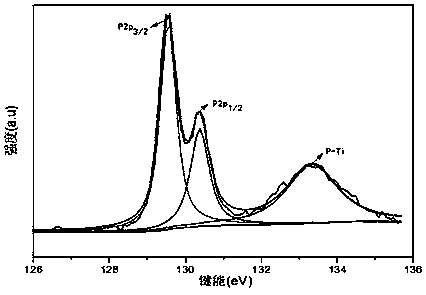

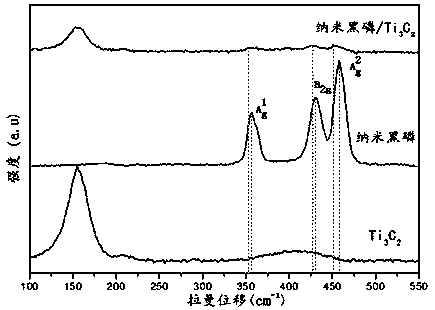

Examples

Embodiment 1

[0023] A method for stabilizing nano black phosphorus, the concrete steps are as follows:

[0024] (1) According to Zhang C, Anasori B, Seral‐Ascaso A, et al. Transparent, Flexible, and Conductive 2D Titanium Carbide (MXene) Films with High VolumetricCapacitance[J]. Advanced Materials, 2017, 29(36) to prepare Ti 3 C 2 , and put Ti 3 C 2 Freeze-dried to obtain Ti 3 C 2 Powder, the specific steps are as follows: under the protection of argon throughout the whole process, first fill the PTFE beaker with argon, then pour 20mL of 8mol / L HCl into it, and then weigh 1g of LiF and Ti 3 AlC 2 (Changchun Nihao Micro-Nano Technology Co., Ltd.) The powder is slowly poured in one by one, stirring with a polytetrafluoro rod for 10 minutes during the period, after sealing the bottle mouth, put it in a magnetic stirrer at 35°C for 72 hours, and then use Deionized water is used for centrifugal washing, followed by suction filtration for separation, and then vacuum drying. The dried powde...

Embodiment 2

[0028] A method for stabilizing nano black phosphorus, the concrete steps are as follows:

[0029] (1) Referring to Zhang C, Anasori B, Seral‐Ascaso A, et al. Transparent, Flexible, and Conductive 2D Titanium Carbide (MXene) Films with High Volumetric Capacitance[J]. Advanced Materials, 2017, 29(36) Ti 2 Preparation of AlC into Ti 2 C water dispersion, which can be freeze-dried to obtain Ti 2 C powder;

[0030] (2) Strip the black phosphorus with an ultrasonic cleaning machine to obtain nano-black phosphorus, and then dry it to obtain nano-black phosphorus powder. Under the protection of nitrogen, the Ti prepared in step (1) 2 C powder and nano black phosphorus powder are mixed according to the mass ratio of 6:1, and the mixture is added to the beaker of dimethyl sulfoxide according to the ratio of mass volume ratio of the mixture to dimethyl sulfoxide of 1:60 (g:mL) In the process, seal the mouth of the beaker after passing nitrogen for 10 minutes, mix with an ultrasonic ...

Embodiment 3

[0032] A method for stabilizing nano black phosphorus, the concrete steps are as follows:

[0033] (1) Will the market buy Mo 2 C prepared Mo 2 C water dispersion, which can be freeze-dried to obtain Mo 2 C powder;

[0034] (2) Ultrasonically strip the black phosphorus with an ultrasonic cleaning machine to obtain nano-black phosphorus, and then dry it to obtain nano-black phosphorus powder. Under the protection of argon, the Mo prepared in step (1) 2 C powder and nano black phosphorus powder are mixed according to the mass ratio of 1:6, and the mass volume ratio of the mixture to 1-ethyl-3-methylimidazole-hexafluorophosphate is 1:100 (g:mL). Add the mixture into the beaker of 1-ethyl-3-methylimidazole-hexafluorophosphate, seal the mouth of the beaker after passing argon gas for 10 minutes, and mix it in an ultrasonic cleaning machine at a temperature of 20°C for 120 minutes, and then perform centrifugation , during the centrifugation process, the whole process is protecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com