Method for preparing laminar MXenes material by utilizing ternary MAX material

A layered and corrosive liquid technology, applied in nanotechnology, chemical instruments and methods, non-metallic elements, etc. for materials and surface science, can solve problems such as uneven corrosion, prolonged corrosion time, incomplete erosion, etc., to achieve Achieve good results, strong operability, and good microscopic appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

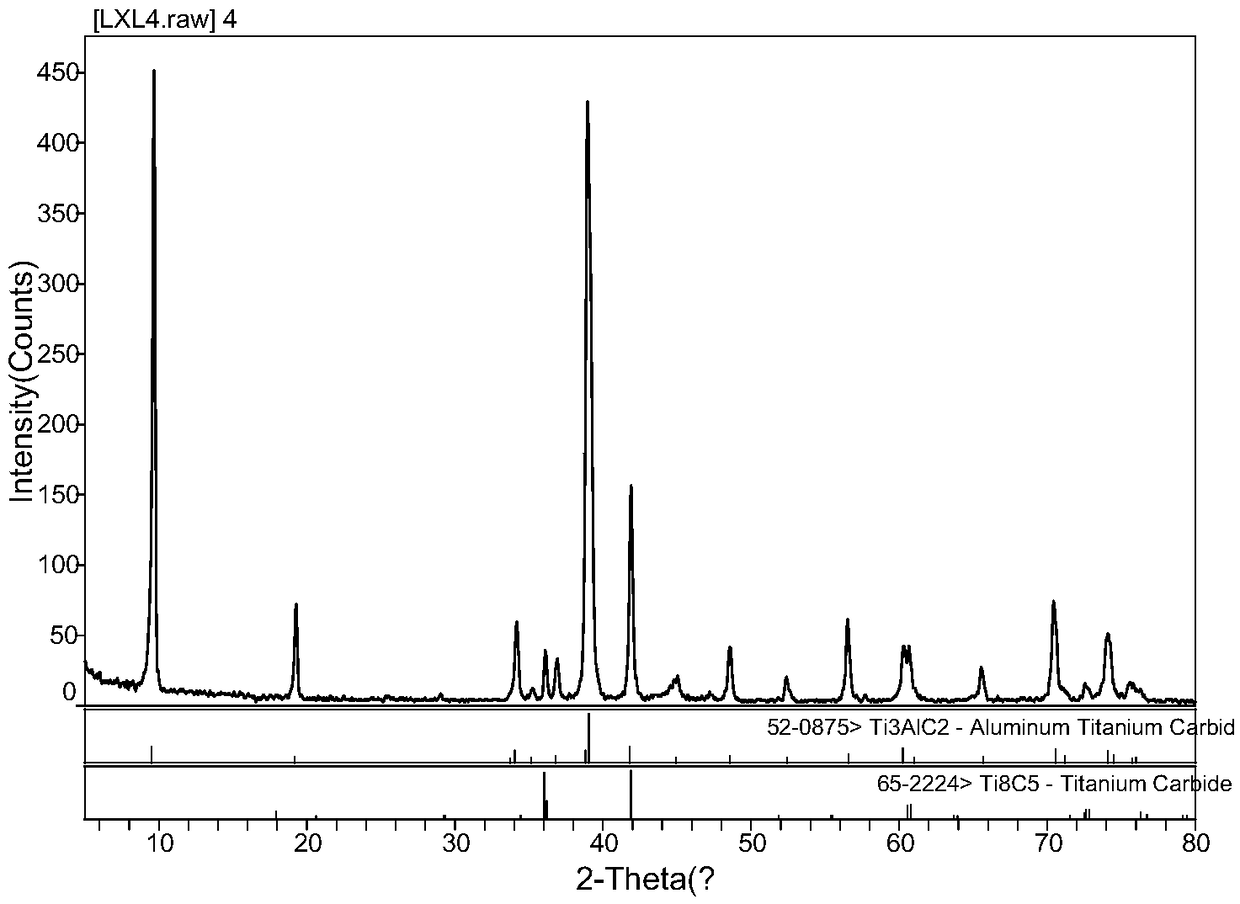

Embodiment 1

[0035] 1) Ti, Al, C, Nb 2 o 5 And the compound K salt is mixed evenly with wet ball milling to obtain a mixture; the specific raw material ratio is shown in Table 1 below, KCl in the compound potassium salt: K 2 SO 4 The molar ratio of the compound potassium salt is 2:1, and the dosage of the compound potassium salt is twice the total weight of all other raw materials.

[0036] The weight percentage of each raw material of table 1 embodiment 1

[0037]

[0038]

[0039] The mixed material was prepared into a slurry with absolute ethanol, and the absolute ethanol:mixed material (mass ratio) was 2.2:1; the slurry was mixed uniformly by ball milling for 2.5 hours. Put the mixed raw materials into a drying oven at a drying temperature of 40°C to prevent oxidation of the raw materials when the temperature is too high. After the ethanol is completely volatilized, the raw materials are ground and pulverized and put into a corundum crucible. In a vacuum furnace, keep warm at ...

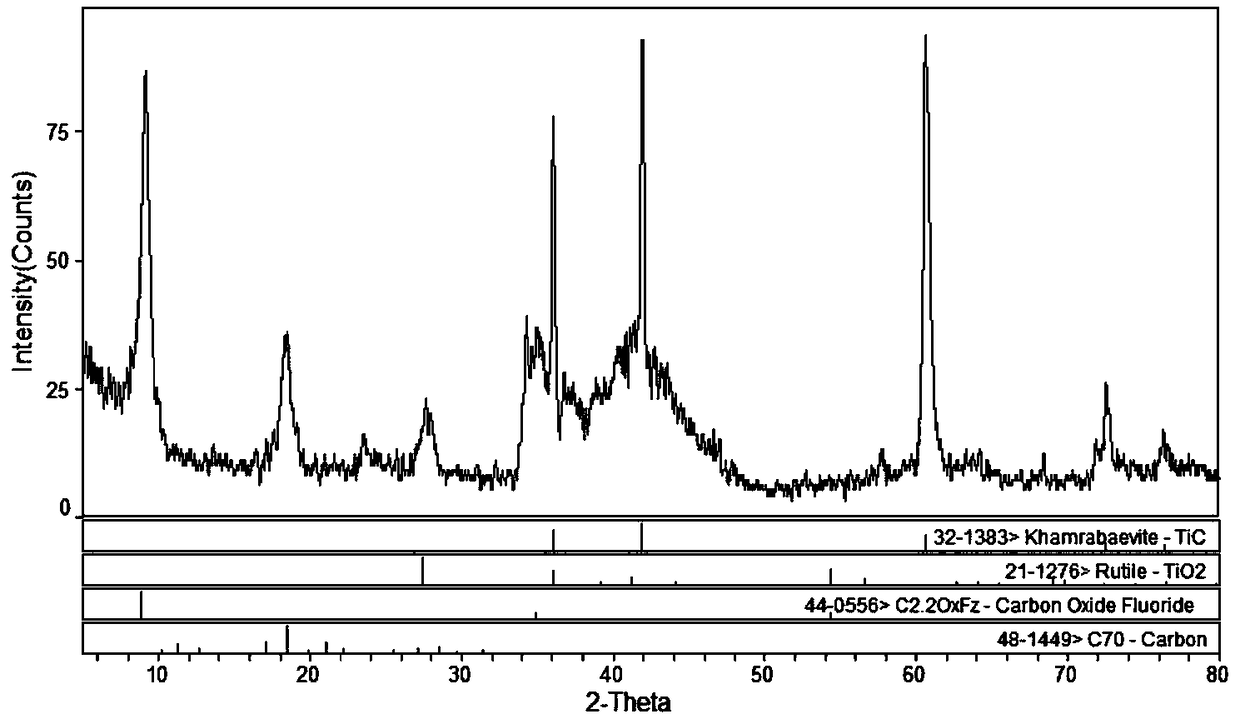

Embodiment 2

[0047] 1) Combine Cr, Al, C, Nb 2 o 5 And the compound K salt is mixed evenly with wet ball milling to obtain a mixture, and the specific raw material ratio is shown in Table 2 below. In the compound potassium salt, KCl: K 2 SO 4 The molar ratio of the compound potassium salt is 1.8:1, and the dosage of the compound potassium salt is twice the total weight of other raw materials.

[0048] The weight percent of each raw material of table 2 embodiment 2

[0049]

[0050]

[0051] The mixed material was prepared into a slurry with absolute ethanol, and the absolute ethanol:mixed material (mass ratio) was 2.2:1; the slurry was mixed uniformly by ball milling for 2.5 hours. Put the mixed raw materials into a drying oven at a drying temperature of 40°C to prevent oxidation of the raw materials when the temperature is too high. After the ethanol is completely volatilized, the raw materials are ground and pulverized and put into a corundum crucible. In a vacuum furnace, keep ...

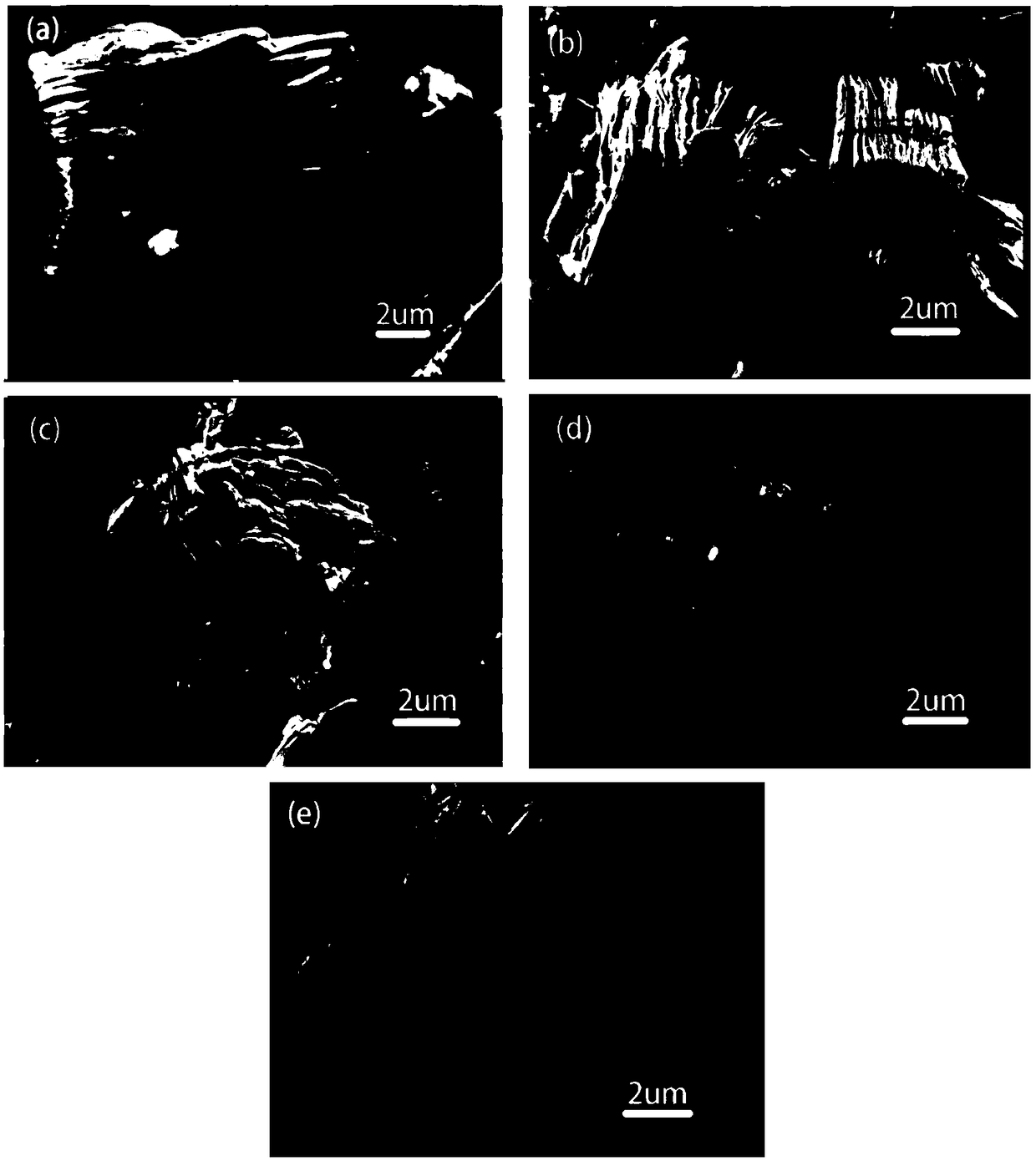

Embodiment 3

[0055] 1) Ti, Mo, Al, C, Al 2 o 3 And the compound K salt is mixed evenly with wet ball milling to obtain a mixture, and the specific raw material ratio is shown in Table 3 below. In the compound potassium salt, KCl: K 2 SO 4 The molar ratio of the compound potassium salt is 4:1, and the dosage of the compound potassium salt is twice the total weight of other raw materials.

[0056] The weight percent of each raw material of table 3 embodiment 3

[0057]

Ti

Mo

Al

C

Al 2 o 3

total

wt.%

24

32.5

27

12

4.5

100

[0058] The mixed material was prepared into a slurry with absolute ethanol, and the absolute ethanol:mixed material (mass ratio) was 2.2:1; the slurry was mixed uniformly by ball milling for 2.5 hours. Put the mixed raw materials into a drying oven at a drying temperature of 40°C to prevent oxidation of the raw materials when the temperature is too high. After the ethanol is completely volatilized, the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com