Preparation method of material similar to graphene

A kind of graphene technology, applied in the direction of carbide, titanium carbide, etc., can solve the problems of incomplete particle corrosion, easy agglomeration of particles, weak connection bonds, etc., and achieve the effect of low cost, simple preparation process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

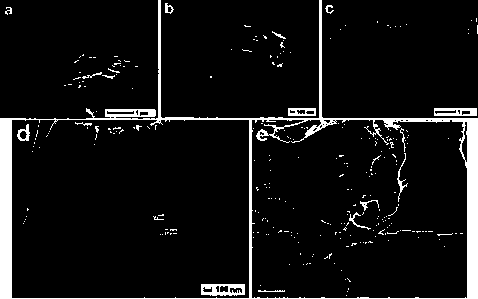

[0017] Ti 3 AlC 2 Grind into powder, sieve under a 200-mesh sieve to obtain uniform particles smaller than 200 mesh, mix 2.5g Ti with magnetic stirring or ultrasonic dispersion 3 AlC 2 Put it into 60ml 40% hydrofluoric acid solution and react for 6 hours, wash the reacted product repeatedly with ethanol and distilled water, then ultrasonically disperse it for 3 hours, then collect the dispersed product by centrifugation or suction filtration, and store the collected product at 50°C Dry for 2 hours.

Embodiment 2

[0019] Ti 3 AlC 2 Grind into powder, sieve under a 200-mesh sieve to obtain uniform particles smaller than 200 mesh, mix 2.5g Ti with magnetic stirring or ultrasonic dispersion 3 AlC 2 Put it in 60ml 40% hydrofluoric acid solution for 12 hours, wash the product after reaction with ethanol and distilled water repeatedly, and disperse it ultrasonically for 3 hours, then collect the dispersed product by centrifugation or suction filtration, and store the collected product at 50°C Dry for 1h.

[0020]

[0021] Example 2:

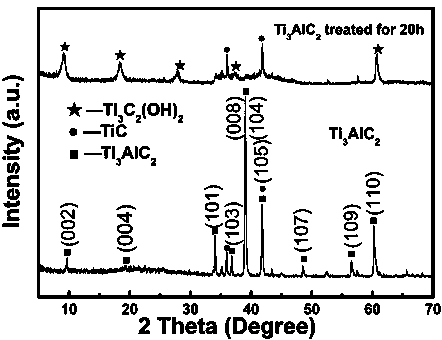

[0022] Ti 3 AlC 2 Grind into powder, sieve under a 200-mesh sieve to obtain uniform particles smaller than 200 mesh, mix 2.5g Ti with magnetic stirring or ultrasonic dispersion 3 AlC 2 Put it in 60ml 40% hydrofluoric acid solution for 20 hours, wash the product after reaction with ethanol and distilled water repeatedly, and disperse it ultrasonically for 3 hours, and then collect the dispersed product by centrifugation or suction filtration. Dry for 2...

Embodiment 3

[0024] Ti 3 AlC 2 Grind into powder, sieve under a 200-mesh sieve to obtain uniform particles smaller than 200 mesh, and mix 2.5g Ti with magnetic stirring or ultrasonic dispersion 3 AlC 2 Put it in 60ml 40% hydrofluoric acid solution for 20 hours, wash the product after reaction with ethanol and distilled water repeatedly, and disperse it ultrasonically for 1 hour, then collect the dispersed product by centrifugation or suction filtration, and store the collected product at 50°C Dry for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com