Electrochemical synthesis method of two-dimensional titanium carbide nanosheet

A technology of two-dimensional titanium carbide and synthesis method, applied in the direction of titanium carbide, carbide, nanotechnology, etc., can solve problems such as operator and environmental damage, high toxicity, etc., and achieve improved rate performance, high conductivity, and thin thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

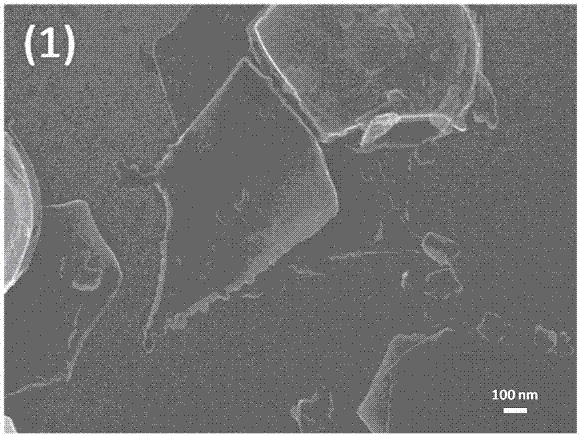

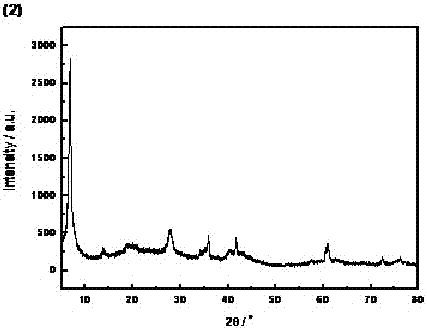

[0017] to Ti 3 SiC 2 The material is the positive electrode, where Ti 3 SiC 2 Electrodes were prepared with Ti 3 SiC 2 The powder material is used as the raw material, which is formed by dry pressing at 50MPa, and then sintered under the protection of argon for 1000 o C, made in 2 hours, to contain NaF and Na 2 SO 4 The mixed aqueous solution is the electrolyte, and its concentration is 0.5 mol L -1 with 2 mol L -1 , with graphite as the negative electrode, the control voltage is 1.2V, and the Ti 3 SiC 2 The electrochemical etching and stripping of the positive electrode can strip the ultra-thin two-dimensional material. After the stripping is completed, the Ti-containing 3 C 2 The electrolyte of the nanosheets is vacuum filtered, washed with deionized water, and freeze-dried to obtain Ti 3 C 2 Nanosheet powder material.

Embodiment 2

[0019] to Ti 3 AlC 2 The material is the positive electrode, where Ti 3 AlC 2 Electrodes were prepared with Ti 3 AlC 2 The powder material is used as the raw material, which is formed by dry pressing at 50MPa, and then sintered under the protection of argon for 900 o C, made in 2 hours, to contain NaF and Na 2 SO 4 The aqueous solution is the electrolyte, and its concentration is 0.2 mol L -1 with 3 mol L -1 , with graphite as the negative electrode, the control voltage was 0.9 V, and the Ti 3 AlC 2 Electrochemical etching and stripping of positive electrode can strip ultrathin two-dimensional Ti 3 C 2 Nanosheet material, after the exfoliation is completed, the Ti-containing 3 C 2 The electrolyte of nanosheets is vacuum filtered, washed with deionized water, and freeze-dried to obtain Ti 3 C 2 Nanosheet powder material.

Embodiment 3

[0021] to Ti 2 AlC material is the positive electrode, where Ti 2 Preparation of AlC electrode with Ti 2 AlC powder material is used as the raw material, which is formed by dry pressing at 40MPa, and then sintered under the protection of argon for 800 o C, made in 2 hours, to contain NaF and Na 2 SO 4 The aqueous solution is the electrolyte, and its concentration is 0.1 mol L -1 with 1 mol L -1 , with graphite as the negative electrode, the control voltage was 0.9 V, and the Ti 2 Electrochemical etching and lift-off of AlC cathode for ultrathin 2D Ti 2 C nanosheet material, after the exfoliation is completed, the Ti-containing 2 The electrolyte of C nanosheets is vacuum filtered, washed with deionized water, and freeze-dried to obtain Ti 2 C nanosheet powder material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com