Preparation method of titanium carbide MXene functionalized graphene nanocomposite film and application thereof

A composite material film, graphene technology, applied in the direction of graphene, titanium carbide, carbon compounds, etc., to achieve the effect of improving mechanical strength and electrical conductivity, reducing porosity, and improving orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

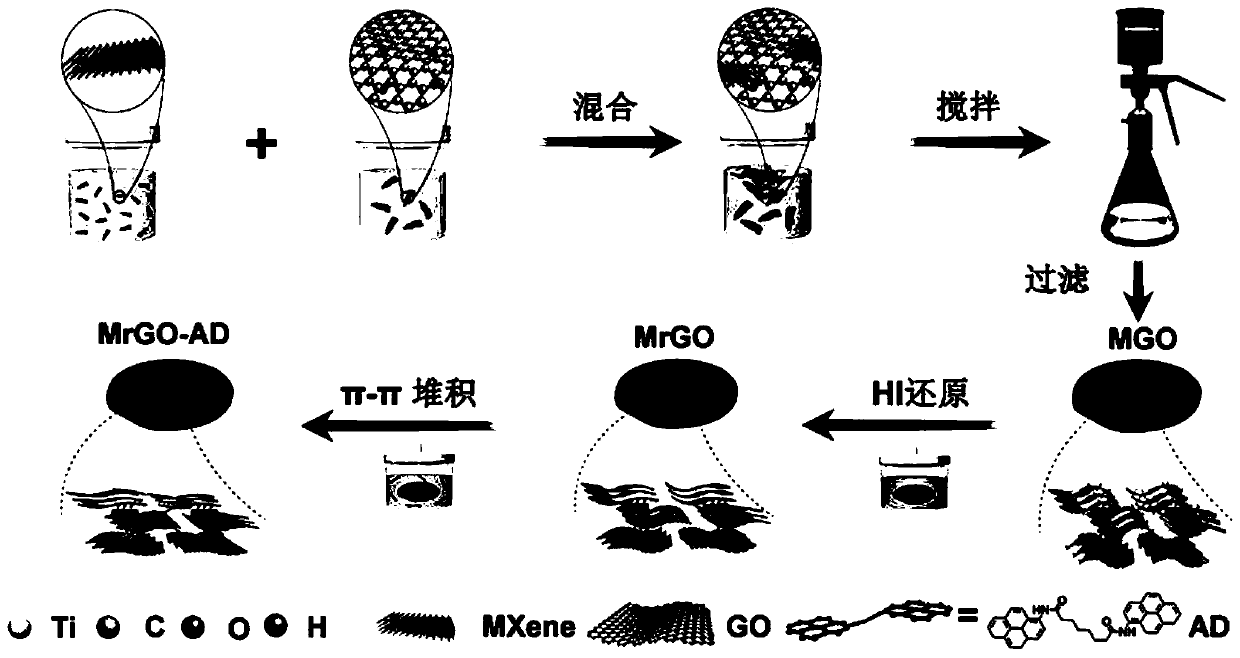

Method used

Image

Examples

Embodiment 1

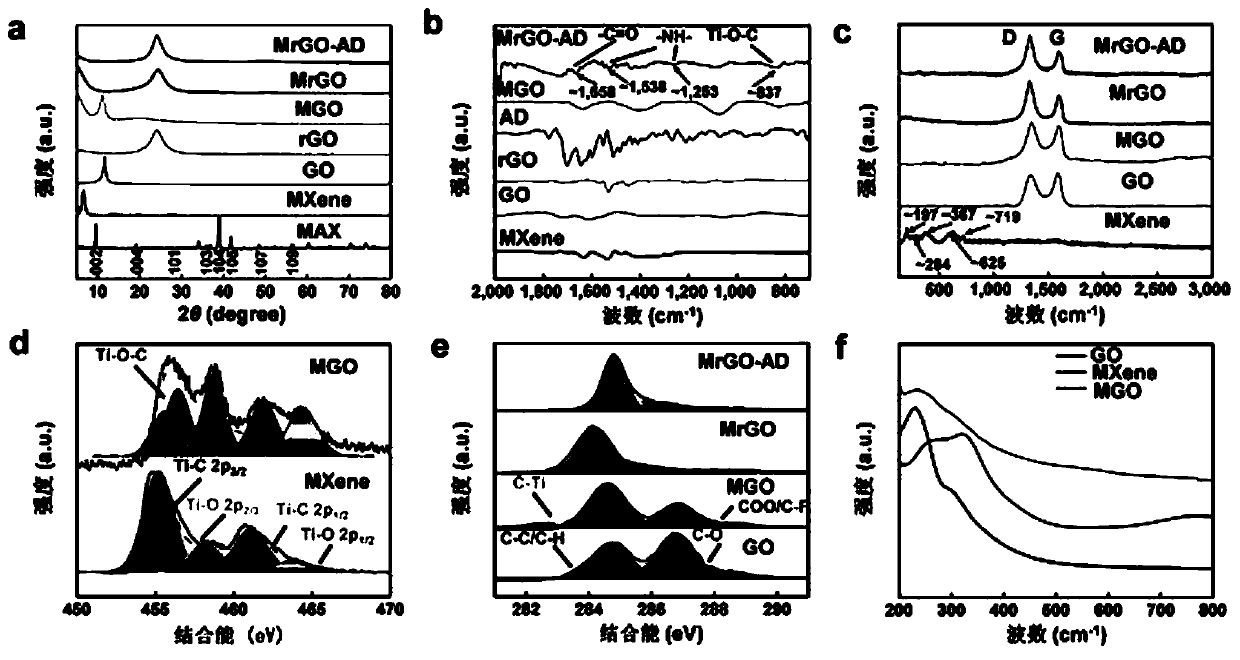

[0045] According to the prepared material XRD spectrum ( figure 2 In a), it is known that the pure MXene film has a characteristic peak of ~6°, and its interlayer spacing is This indicates that the MXene nanosheets successfully synthesized from Ti 3 AlC 2 The stripping was successful. When adding MXene nanosheets, the interlayer spacing of MGO thin films changed from that of pure GO up to It shows that MXene nanosheets were successfully introduced into the interlayer of GO. After HI reduction, the interlayer spacing of MrGO decreased to This indicates that a large number of oxygen-containing functional groups on the surface of GO nanosheets have been removed. When AD molecules are introduced, the interlayer spacing of MrGO-AD films increases to Infrared spectroscopy (FTIR) measurements show that MGO, MrGO and MrGO-AD thin films have a wavelength of ~837cm -1A new characteristic peak appeared in both, indicating the formation of Ti-O-C covalent bonds between MXe...

Embodiment 2

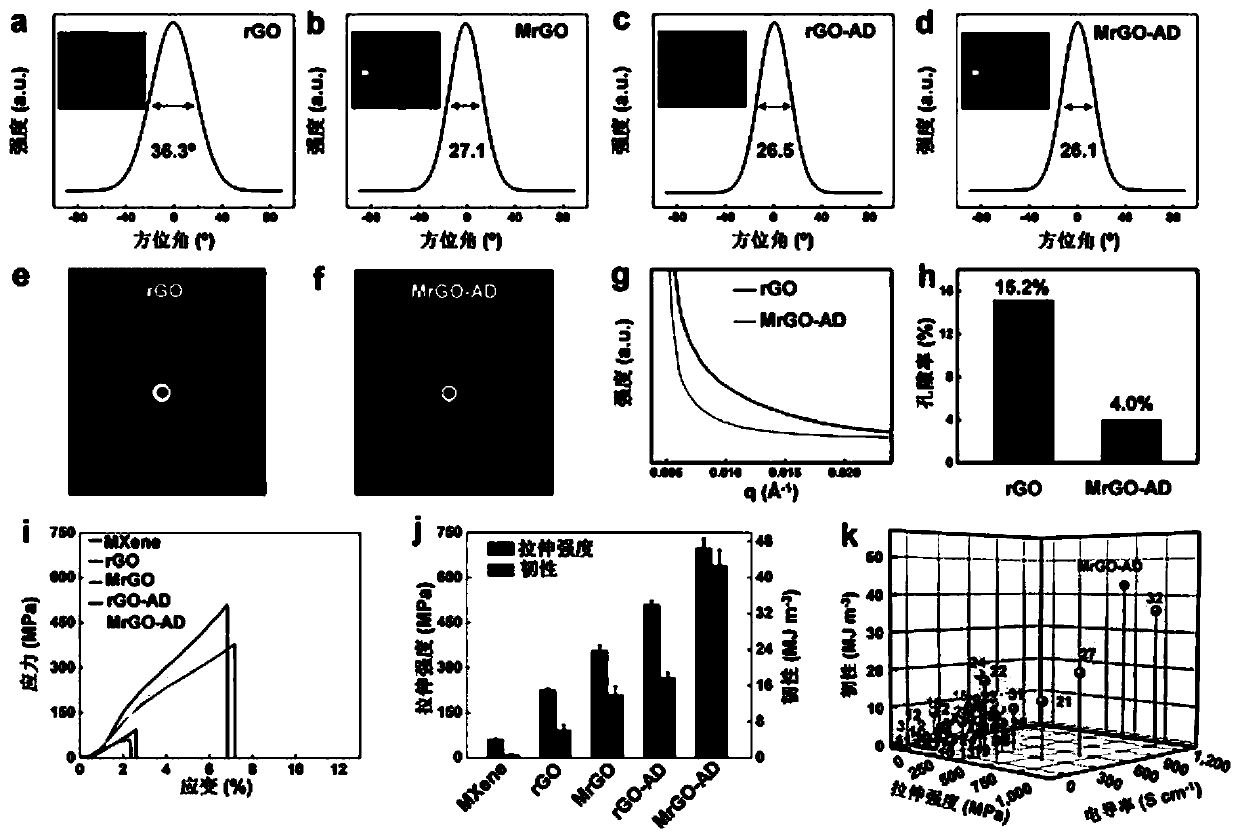

[0047] After functionalizing GO nanosheets with MXene, the azimuthal half-width of the obtained MrGO film decreased from 36.3° to 27.1° in the pure GO film, as image 3 shown in a-d. When the rGO nanosheets were cross-linked with AD molecules through π-π conjugate stacking, the azimuthal half-maximum widths of rGO-AD and MrGO-AD decreased to 26.5° and 26.1°, respectively. Therefore, the MrGO, rGO-AD, and MrGO-AD films exhibit high degrees of orientation of 84.9%, 85.3%, and 85.5%, respectively, while the pure rGO film is only 79.8%. Besides, according to the small-angle scattering test, the porosity of MrGO-AD decreased from 15.2% to 4.0% of the pure rGO film, these results suggest that MXene nanosheets can fill the interlayer pores of rGO, thus making the film more compact. Due to the interfacial synergy between MXene nanosheets, rGO nanosheets, and AD molecules, the rGO film becomes more compact and the orientation degree of rGO is improved, which improves the mechanical pr...

Embodiment 3

[0049] In situ Raman spectroscopy characterized the G-band migration of graphene nanosheets, showing the difference in the loading transfer efficiency of pure rGO, rGO-AD, MrGO and MrGO-AD thin films. Such as Figure 4 As shown in a–d, when MXene nanosheets are cross-linked with human GO nanosheets through Ti-O-C covalent bonds, the formed MrGO film obviously has a long platform between 0.9%-4.3% strain, similar to that of pure rGO thin films (plateaus appear at 0.5%–3.6%), and the upper plateau represents the beginning of MrGO cracking, and MXene-functionalized MrGO completely fractures at high strain ~6.7%. The emergence of this platform shows that the stress cannot be effectively transmitted to the graphene nanosheets due to the slippage between the MXene nanosheets, resulting in plastic deformation, which makes the tensile strength and toughness of the prepared MXene functionalized graphene nanocomposite film Effective promotion. At the same time, the breaking of Ti-O-C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com