Physical forms of MXene materials exhibiting novel electrical and optical characteristics

A performance, capacitance technology, applied in the direction of tungsten/molybdenum carbide, chemical instruments and methods, circuits, etc., can solve expensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

[0227] Example 5: General Comments

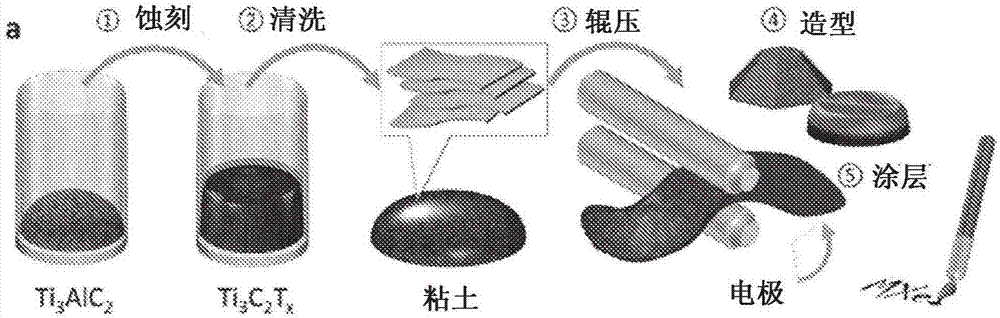

[0228] m n+1 x n (T s ) MXenes, a relatively new class of 2D solids produced by selective etching of group A layers from MAX phases, are a family of more than 70 members of hierarchical hexagonal anterior transition metal carbides and nitrides. So far, all M n+1 x n (T s ) MXenes were all produced by etching the MAX phase in concentrated hydrofluoric acid HF or ammonium bifluoride. m n+1 x n (T s ) MXenes have proven to be promising candidates for electrodes in Li-ion batteries and supercapacitors, exhibiting volumetric specific capacitances exceeding most previously reported materials. However, the road to electrode fabrication requires operations in concentrated HF and tedious multi-step procedures. Here, a safer route was sought by exploiting the reaction between the commonly used and inexpensive hydrochloric acid HCl and fluoride salts. Furthermore, considering the M n+1 x n (T s ) MXenes are capable of preferential interc...

Embodiment 1

[0230] Example 1. Materials and Methods - Clay

Embodiment 11

[0231] Example 1.1.Ti 3 AlC 2 Synthesis of : used as precursor in this paper for Ti 3 C 2 (T s ) synthesized MAX phase Ti 3 AlC 2 Prepared as follows: commercial Ti 2 AlC powder (Kanthal, Sweden) to TiC in a 1:1 molar ratio (for ~12 wt.% Ti already present in the commercial powder 3 AlC 2 After adjustment) mixed, then ball milled for 18h. The mixture was then heated in a tube furnace at 1350° C. for 2 h at 5° C. / min under flowing argon gas Ar. The resulting lightly sintered brick was ground with a TiN-coated milling bit and sieved through a 400 mesh screen to yield a powder with a particle size of less than 38 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com