Dynamic vulcanization of fluorocarbon elastomers

a technology of vulcanization and fluorocarbon elastomers, which is applied in the field of dynamic vulcanization of fluorocarbon elastomers, can solve the problems of difficult recycling and reuse of scrap generated in the manufacturing process, the inability to generally be and the inability to cure elastomeric materials to be generally processed by conventional thermoplastic techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples

[0107] In Examples 1-10, the following materials are used:

[0108] AFLAS MZ is a copolymer elastomer of tetrafluoroethylene and propylene, sold by Asahi Glass Company. It is supplied by Asahi pre-formulated with a phenol crosslinking compound.

[0109] AFLAS SZ is another grade of TFE / propylene elastomer pre-formulated with a phenol crosslinking compound.

[0110] AFLAS SP is a copolymer elastomer of tetrafluoroethylene and propylene. It is formulated without a crosslinking compound.

[0111] Hytrel is Hytrel 4556, 5526 or 8139, a thermoplastic elastomer comprising blocks of polyester and blocks of polyether, sold by DuPont.

[0112] MT Black is a carbon black filler.

[0113] MgO is magnesium oxide, which acts as an acid accepting curing accelerator.

[0114] Ca(OH)2 is calcium hydroxide, another acid accepting curing accelerator.

[0115] Pebax is Pebax MX 1205, 4033, MV 1074, or MH 1657, grades of a thermoplastic elastomer having blocks of polyamide and blocks of polyether, sold by Atofina.

[01...

examples 17-18

[0124] Viton F605C is a VDF / HFP / TFE terpolymer elastomer from DuPont Dow Elastomers.

[0125] Genestar PA9T is C9 diamine based aromatic polyamide. It is a high temperature polyamide based on a copolymer of terephthalic acid and nonanediamine, commercially available from Kuraray.

[0126] Dyneon FE 5840 is a terpolymer elastomer of VDF / HFP / TFE, from Dyneon (3M).

[0127] Dyneon BRE 7231X is a base resistant elastomer, based on a terpolymer of TFE, propylene, and VDF, commercially available from Dyneon (3M).

[0128] Rhenofit CF is a calcium hydroxide crosslinker for fluoroelastomers, from Rhein Chemie.

[0129] Elastomag 170 is a high activity powdered magnesium oxide from Rohm and Haas.

[0130] MT Black (N990) is carbon black.

[0131] Struktol WS-280 is a silane coupling agent from Struktol.

[0132] Technoflon FPA-1 is a functionalized perfluoropolyether from Ausimont.

[0133] Examples 17-19 were carried out in a batch process in a Brabender mixer. The thermoplastic polymer is melted in the batc...

example 19

[0134] For Example 19, 100 parts of Viton F605 was dynamically vulcanized with 125 parts of Nylon 66 according to the conditions of Examples 17-18. The fluorocarbon elastomer made up 44.4% by weight of the total elastomer and thermoplastic combined. The processable rubber composition was molded into a tensile bar for testing of tensile strength and elongation at break.

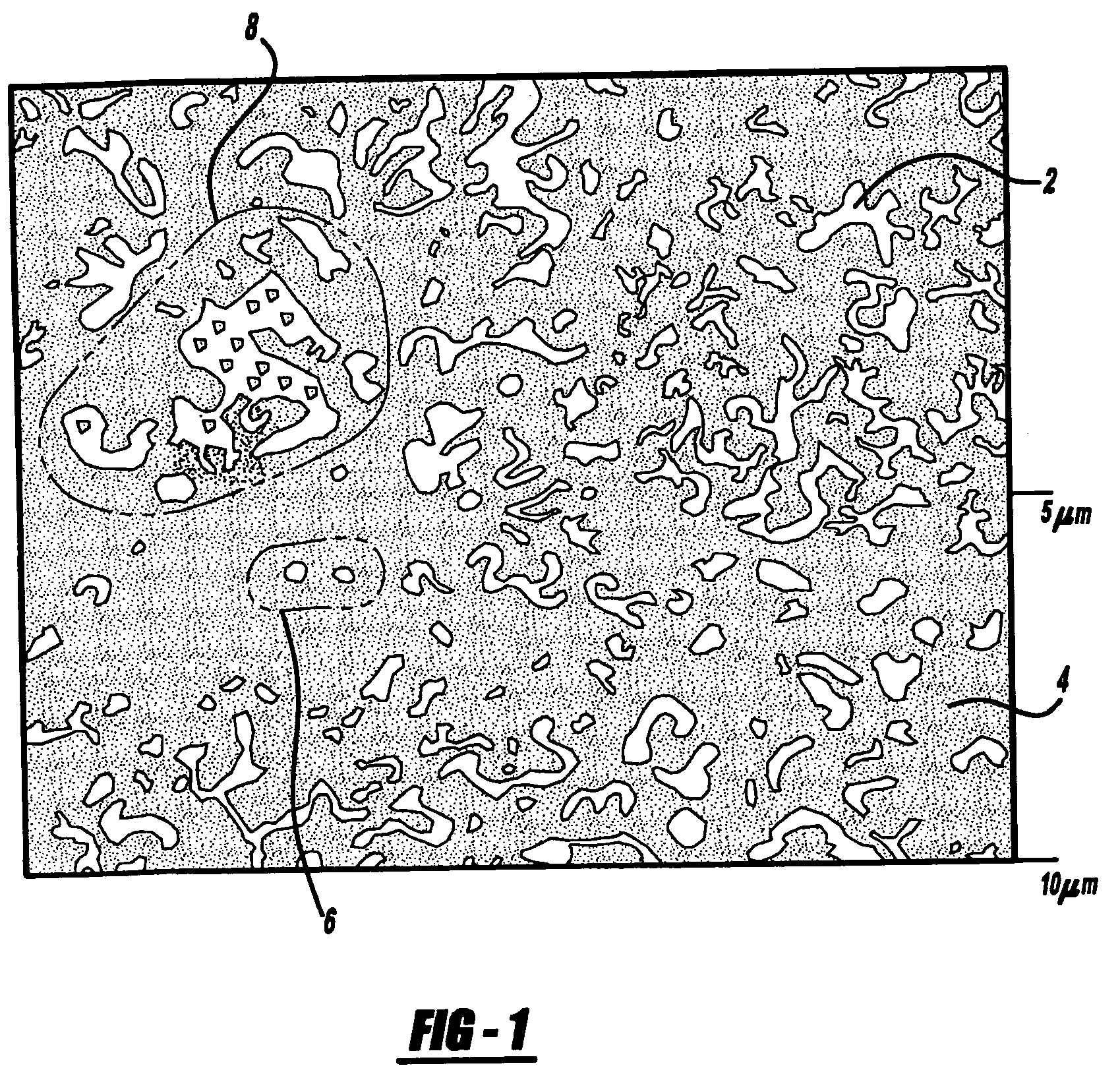

[0135] The middle portion of the tensile bar was cut out of the bar and encased in a ½ inch block of epoxy. The block was taken down to liquid nitrogen temperature, and the shaped article was microtomed to produce a specimen for analysis with an atomic force microscope (AFM).

[0136] The AFM was used in intermittent contact mode, permitting phase and topography images to be obtained simultaneously. Resolution was 1024 data points per scan line and 1024 lines per image. The scan rate was 2 Hz, and the X and Y axis were set at 20 μm by 20 μm. A built-in image analyzer allowed the total for each domain to be calculated. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com