Preparation for application onto a cellulosic fabric or textile material and textile articles comprising same

a cellulosic fabric and textile material technology, applied in the field of textiles, can solve the problems of inability to maintain the stability or performance of known textile articles comprising cellulosic fabric materials with functional additives to enhance functional utility, and the loss of known clothing articles made from cellulosic fabric materials with functional additives to enhance ultraviolet protection or bacteria resistance after several washing cycles, etc., to achieve the effect of enhancing the durability of functional enhancements of cellulosic fabric materials,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

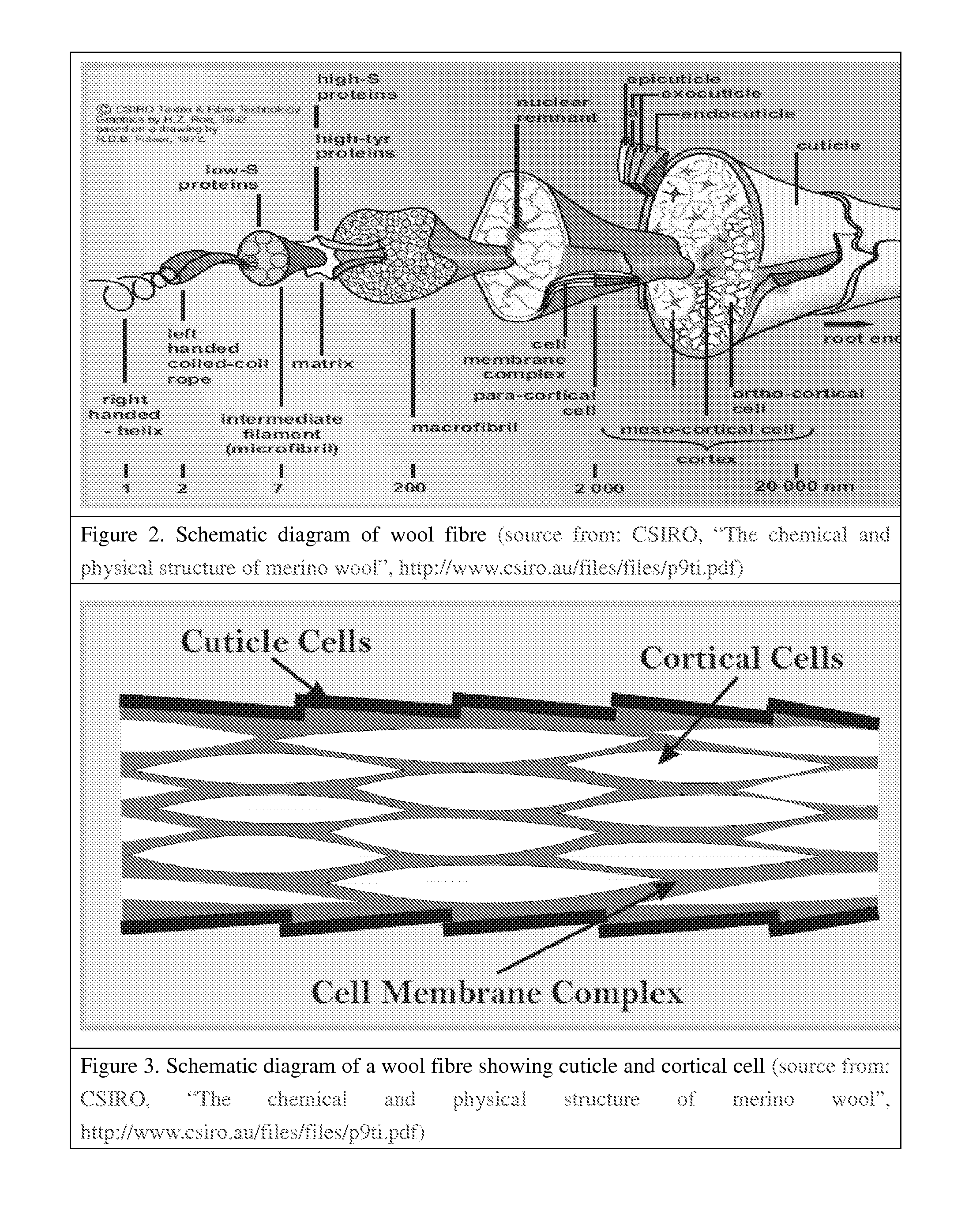

[0044]A cotton tee shirt (“T-shirt”) 100 as an example of a textile article comprising a cellulosic fabric or textile material 110 and applied with a preparation 120 comprising ultrafine wool powder is depicted in FIG. 1. The preparation is an aqueous suspension comprising a functional additive, ultrafine wool powder, and an aqueous binder. The ultrafine wool powder is a wool powder of the macrofibril size which has been found to demonstrate exceptional carrying and retention capability for functional additives. The term “functional additive” in the present context means an additive which confers useful function or utility to the article to which it is applied. Examples of useful function in the present context include ultraviolet (“UV”) protection, anti-bacterial properties, etc.

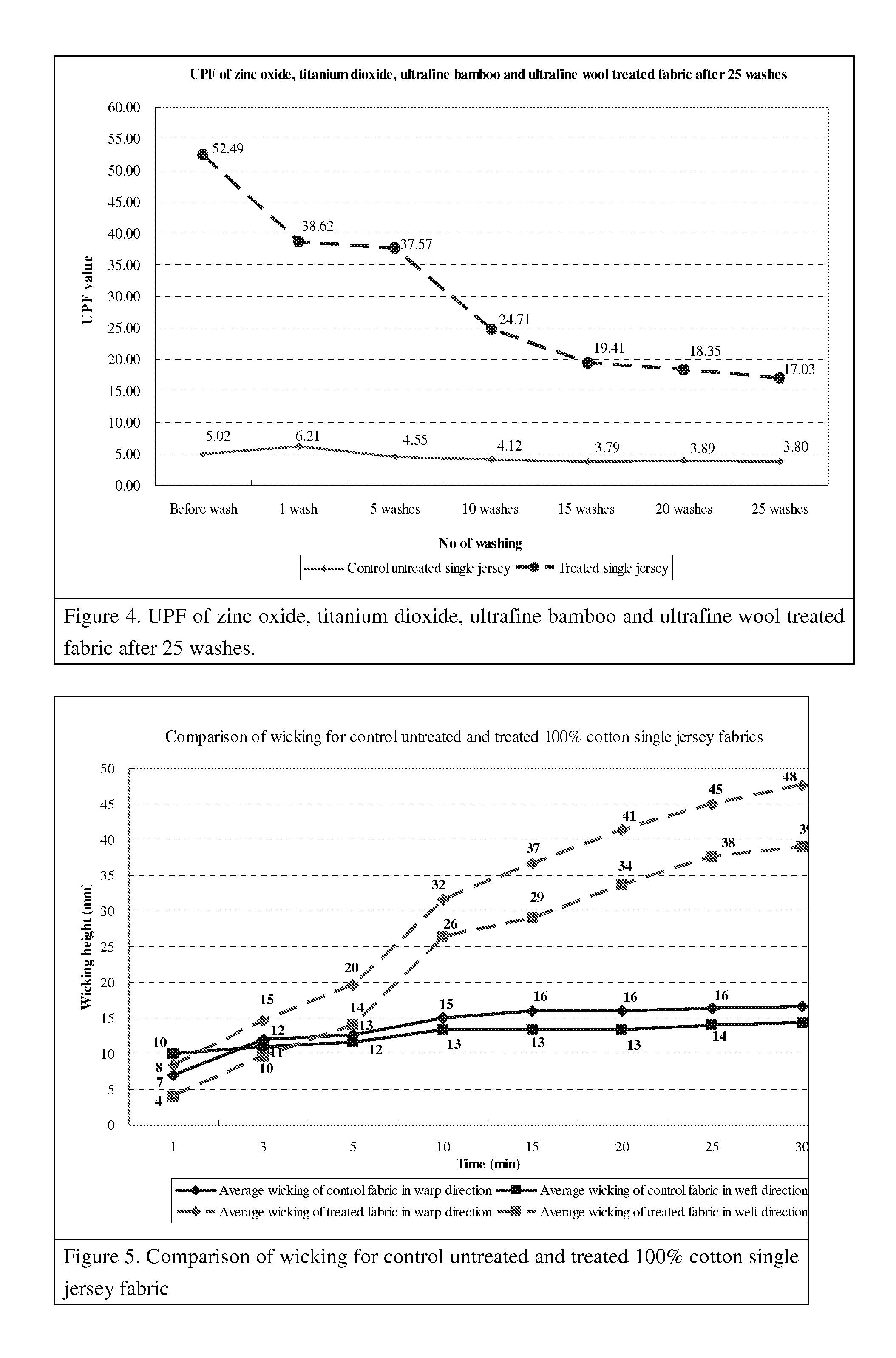

[0045]Examples of known functional additives for ultraviolet protection and / or anti-bacterial property include: zinc oxide or ultrafine zinc oxide, titanium dioxide or ultrafine titanium dioxide.

[0046]Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com