Flaky colorful coating particle granulator

A technology of multi-color paint and granulator, applied in the direction of granulation in static tanks/troughs, etc., can solve the problems of inconsistent stability of flaky colorful paint particles and low production efficiency, and achieve high production efficiency, good stability, The effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

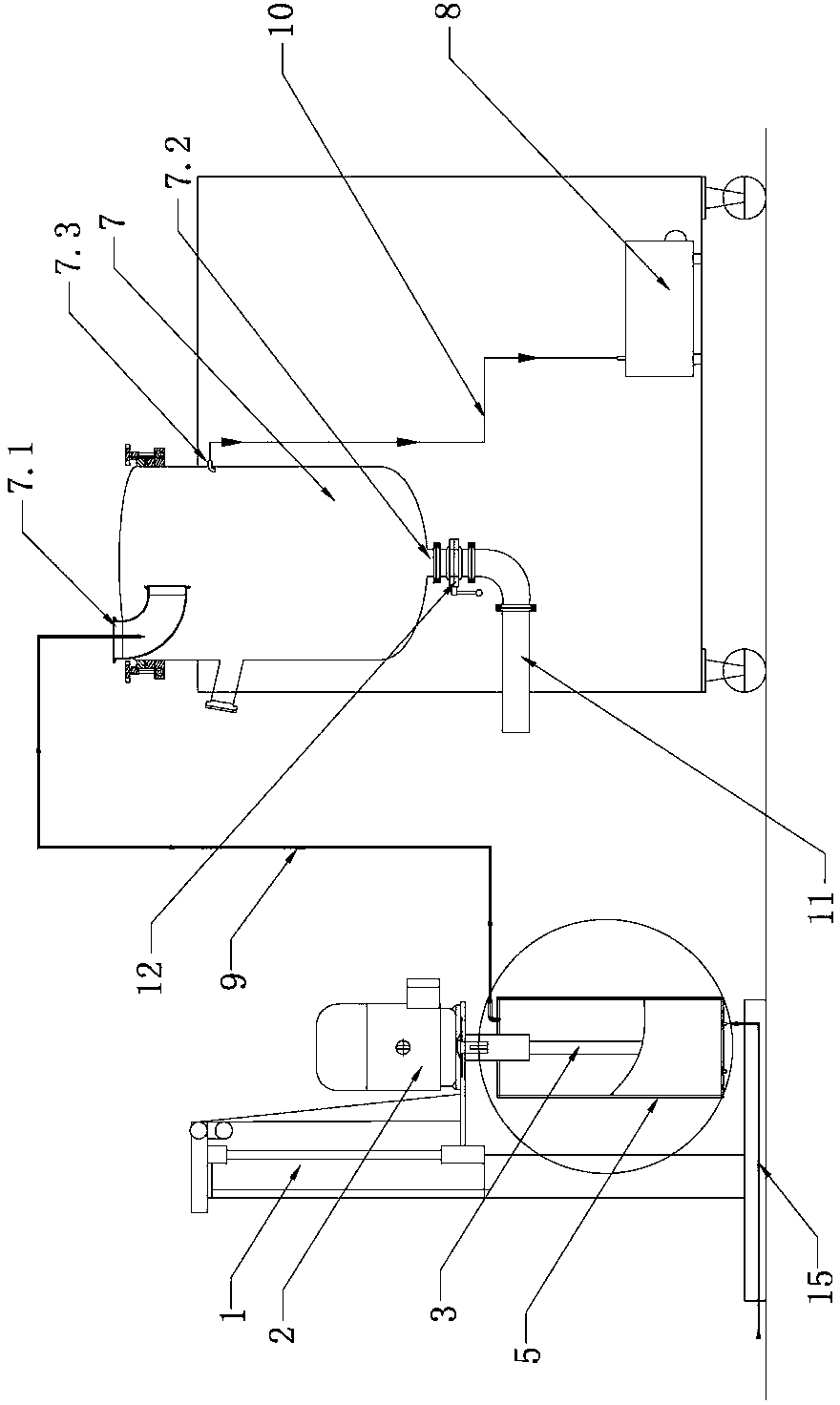

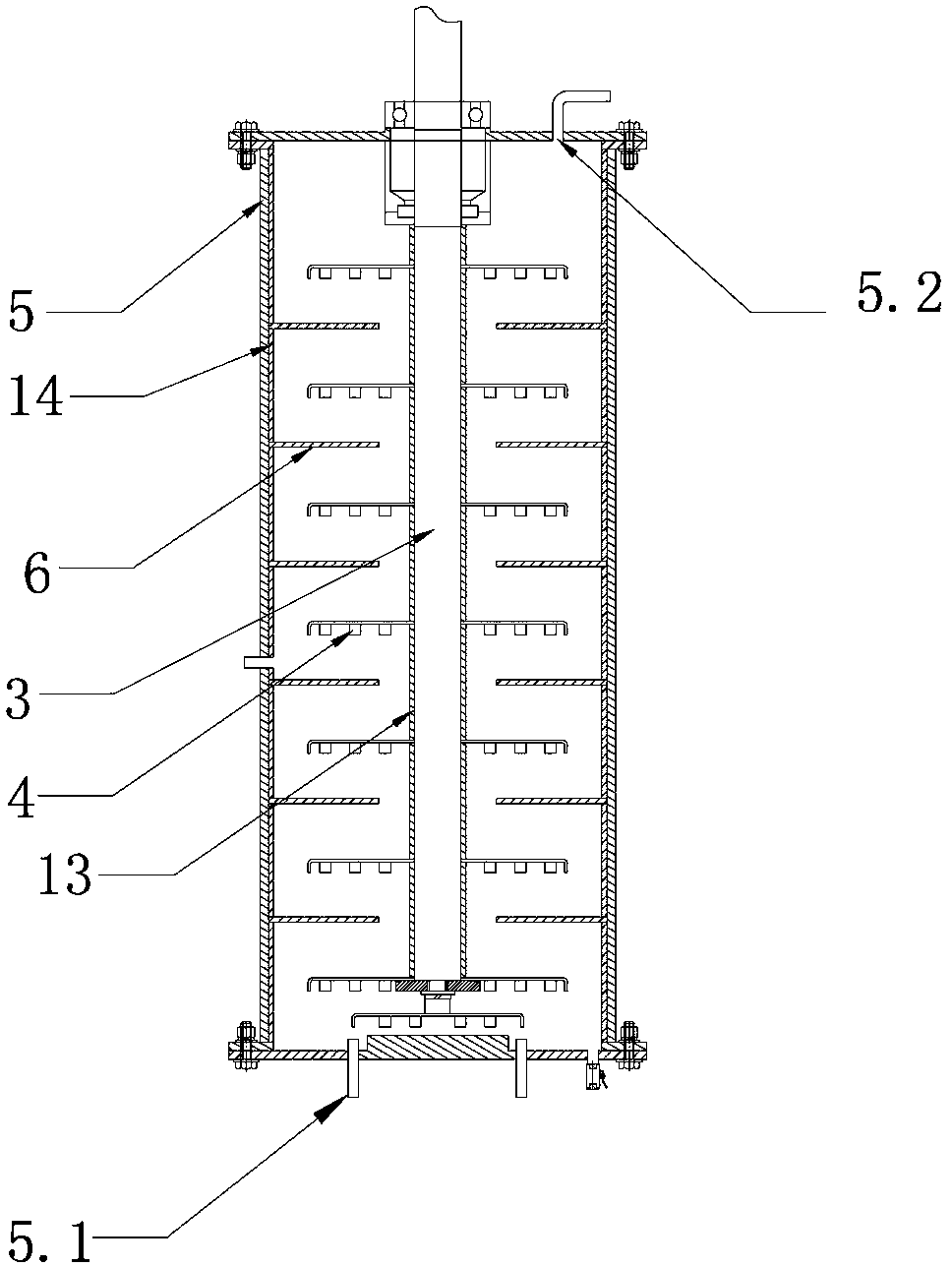

[0010] Such as figure 1 with figure 2 As shown, a granulator for sheet-like colorful paint particles includes a frame 1, a motor 2, a rotating shaft 3 and a dispersion disc 4; it is characterized in that it also includes a barrel 5, an annular deflector 6, a hopper 7, and a vacuum pump 8 , feeding pipe 9, ventilation pipe 10, discharge pipe 11, butterfly valve 12, dispersion disc support sleeve 13 and annular deflector support sleeve 14; material barrel 5 is installed on frame 1, and motor 2 is installed on the upper end of material barrel 5 On the rack 1, one end of the rotating shaft 3 is connected with the motor 2, and the other end of the rotating shaft 3 extends into the material barrel 5, and several dispersion discs 4 are arranged on the rotating shaft 3 extending into the material barrel 5. A dispersing disc support sleeve 13 is provided on the rotating shaft 3 between the discs 4; an annular baffle 6 is provided on the inner wall of the barrel 5 between two adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com