Wet granulation machine

A technology of wet granulator and granulation tower, which is applied in the field of mixing granulation equipment, can solve the problems of high energy consumption and difficult cleaning, achieve good sealing effect, improve efficiency and reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

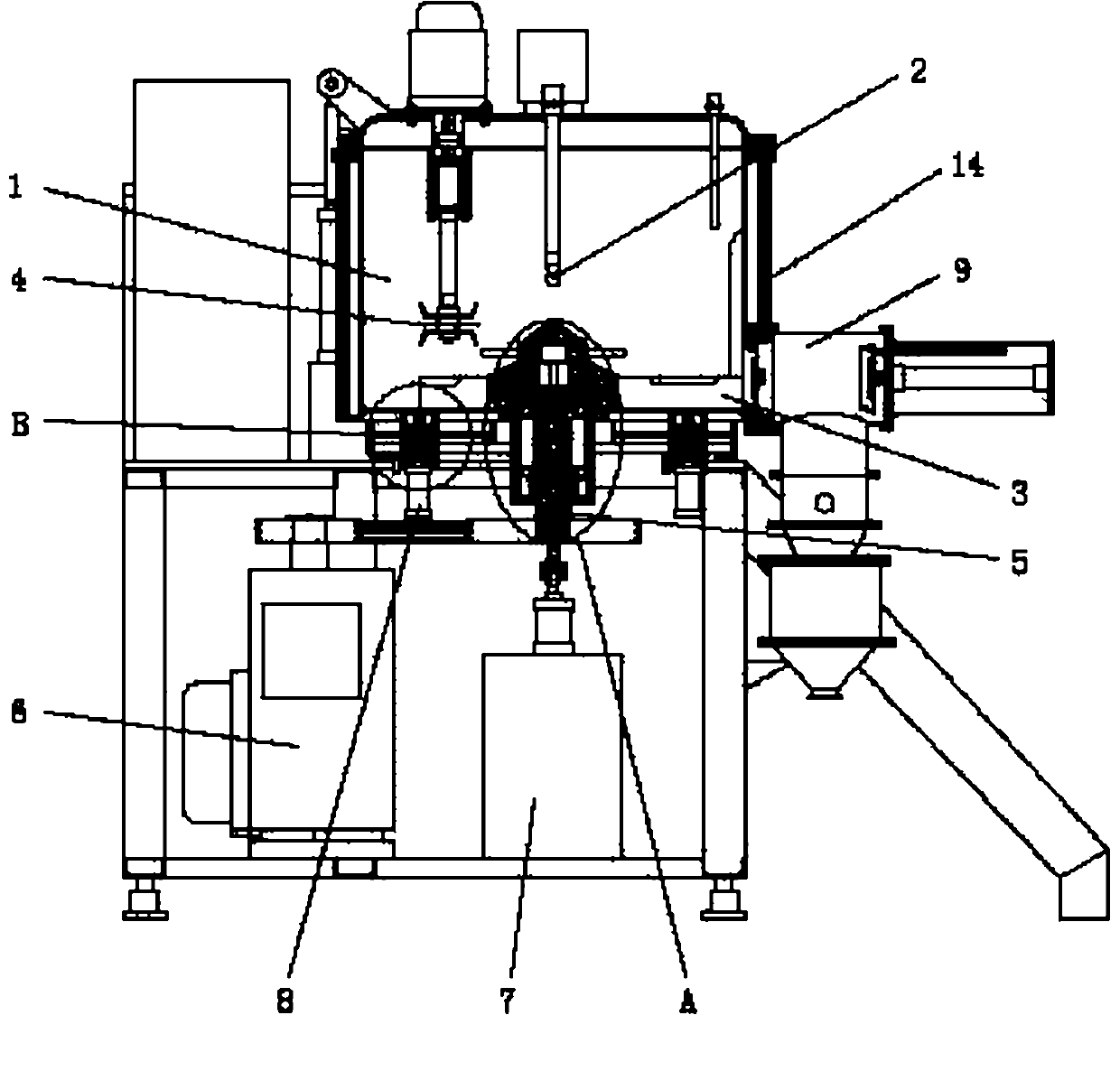

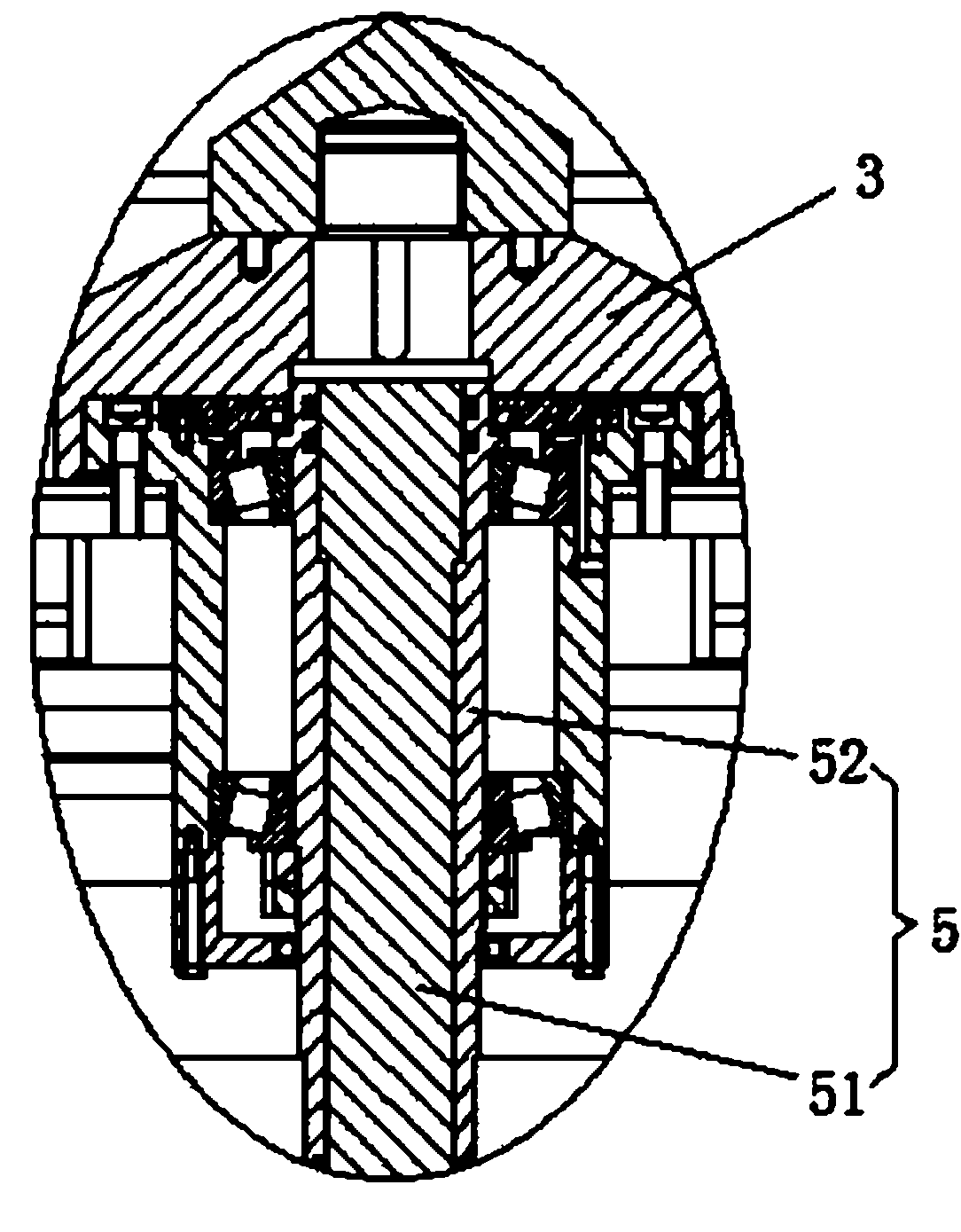

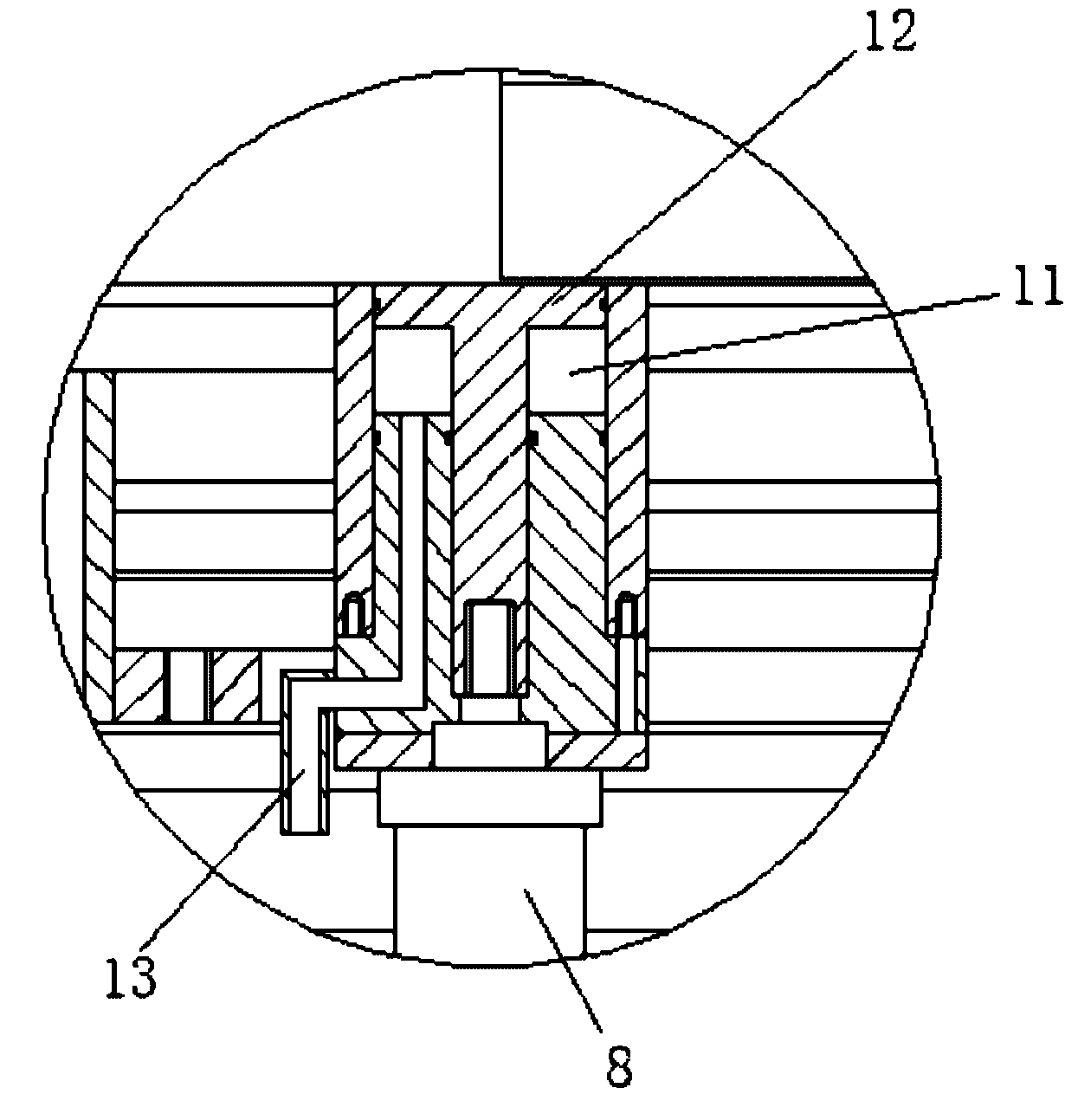

[0022] See figure 1 and figure 2 , the present invention has a granulation tower 1, the tower wall of the granulation tower 1 is provided with an insulating layer 14; Mechanism 9, the stirring paddle 3 is connected to the driving motor 6 outside the prilling tower 1 through the shaft 5; , the cross section of the mandrel 51 and the cross section of the inner hole of the sleeve shaft 52 are profiles that cooperate with each other. The mandrel 51 slides up and down in the sleeve shaft 52. The upper end of the mandrel 51 is connected with the stirring paddle 3, and the lower end extends out of the sleeve shaft 52 and the cylinder 7 connection, a sealing ring is provided between the core shaft 51 and the sleeve shaft 52, and a pulley is provided at the lower end of the sleeve shaft 52, and the drive motor 6 transmits power to the sleeve shaft 52 through the pulley, and the sleeve shaft 52 transmits power to the core shaft 51, the core The shaft 51 drives the stirring paddle 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com