Wet mixing pelletizer having tangent stirring blade

A wet mixing and stirring paddle technology, which is applied in the direction of granulation in static tanks/tanks, can solve the problems of long mixing time, low production efficiency, poor mixing effect, etc., so as to improve production efficiency and mixing effect, and improve mixing. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the present invention will be further described in detail in conjunction with the accompanying drawings.

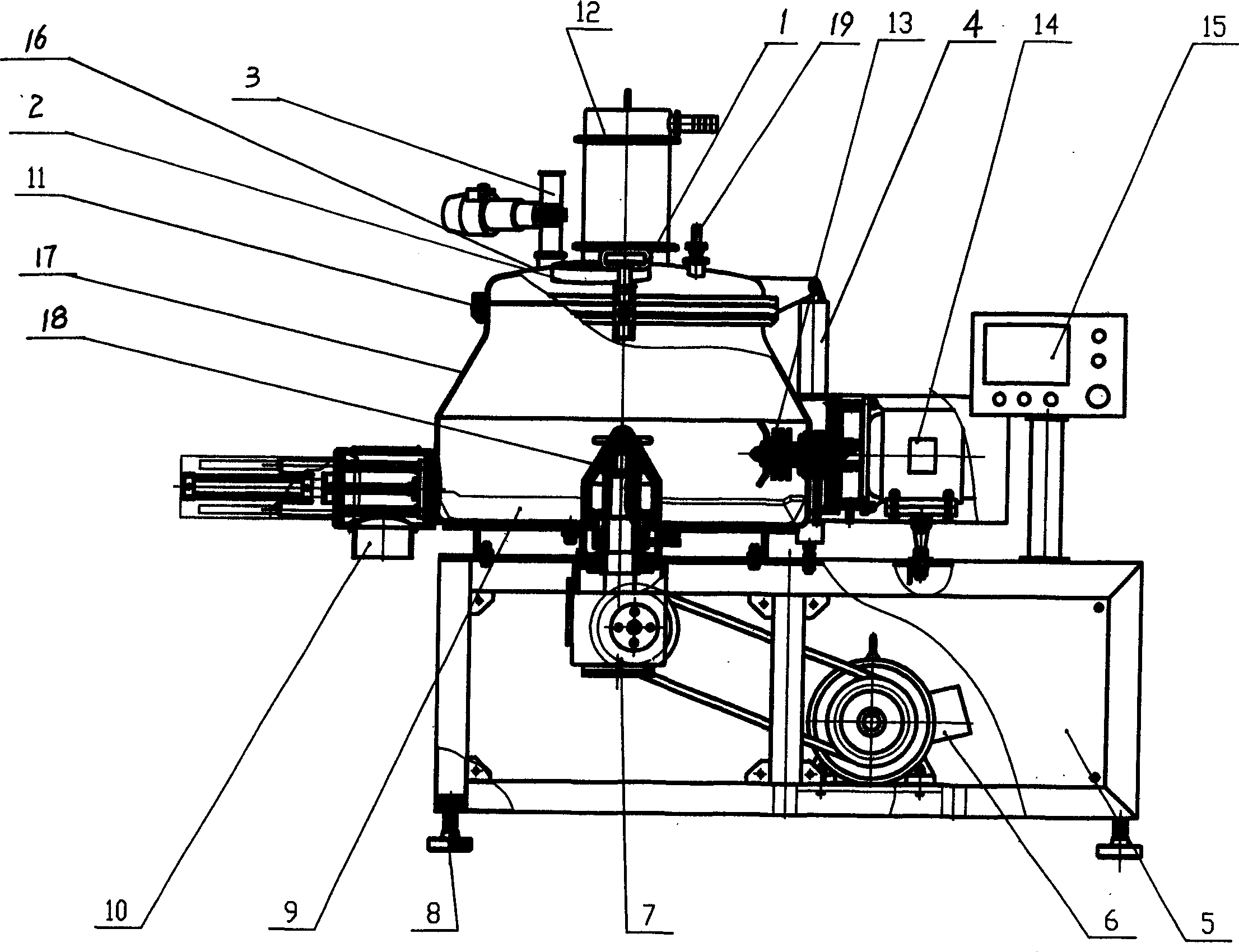

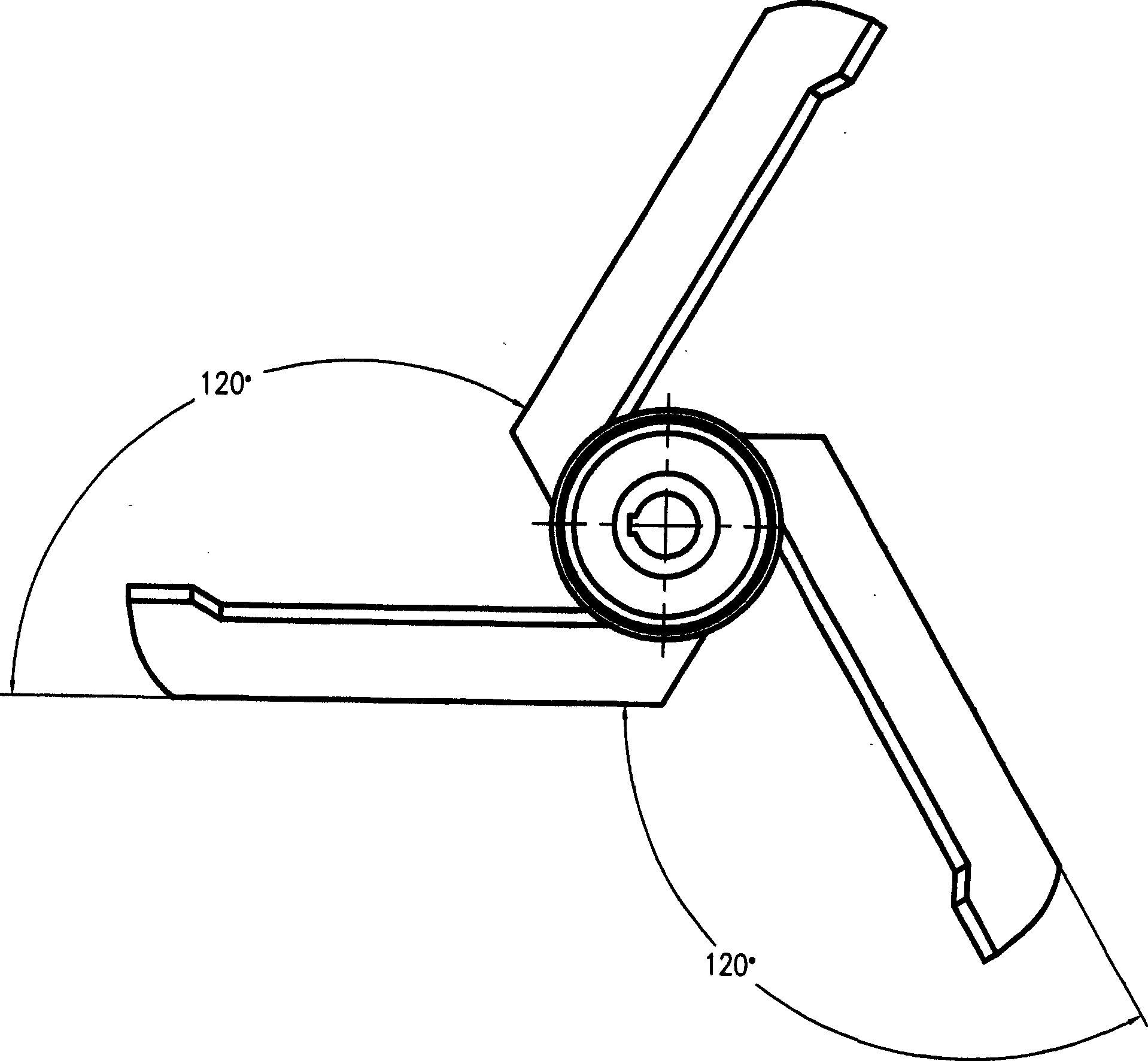

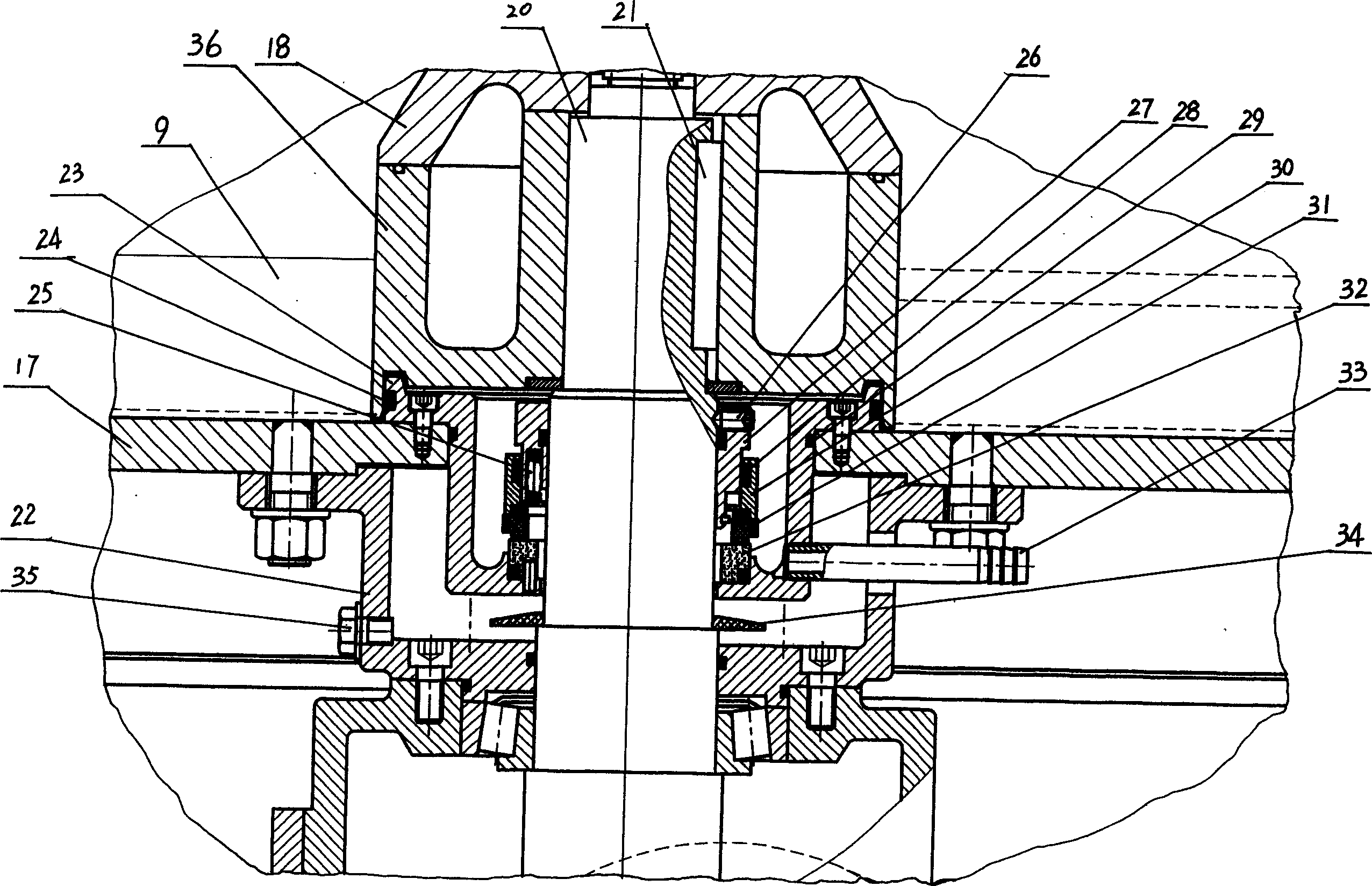

[0012] Such as figure 1 , figure 2 The wet mixing granulator shown includes a base 5, a material cylinder 17, a stirring mechanism, a granulating mechanism, a spray gun mechanism 19, a discharge valve mechanism 10, a sealing mechanism, a feeding port 3 and an operation panel 15. The stirring mechanism is composed of a transmission device 7 and a stirring paddle 9. The stirring paddle 9 is arranged at the bottom of the material cylinder 17, and a sealing mechanism is provided between the stirring paddle transmission device and the material cylinder; the upper part of the material cylinder 17 has a tapered cavity wall; the spray gun mechanism 19 Set on the cylinder head 16 at the top of the material cylinder 17; the granulation mechanism is composed of a transmission device 14 and a granulation knife 13, and the granulation knife 13 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com