Preparation of methyl tributanoximo silane

A technology of methyl tributanone oxime and silane, which is applied in the field of preparation of methyl tributyl ketoxime silane, can solve the problems that the reactants are easy to contact with air, the production cannot be carried out continuously, the process is not safe, etc., and the product is effective. High content, high utilization rate, good volatility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

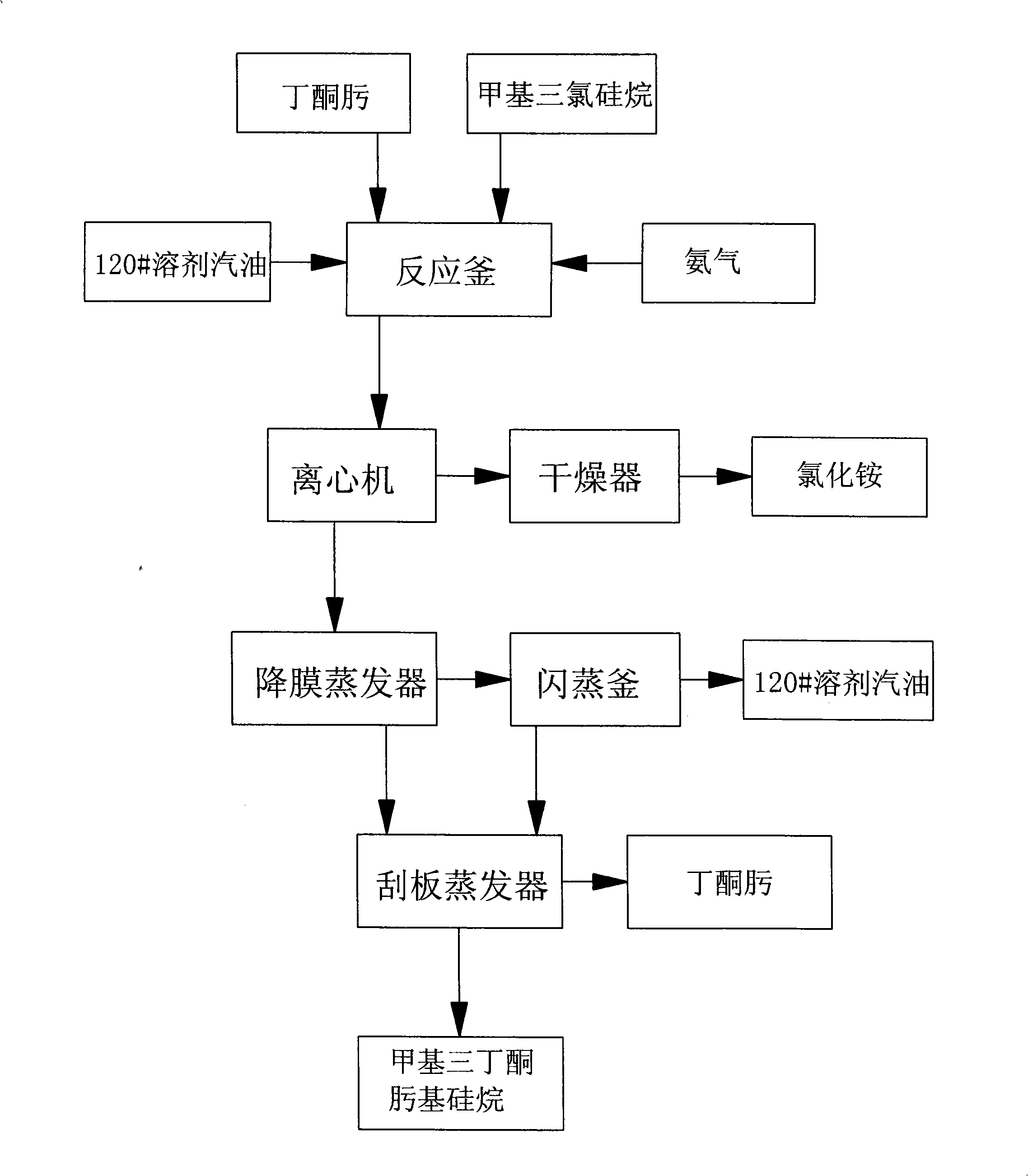

[0019] Methyltrichlorosilane, butanone oxime, ammonia, and 120# solvent gasoline are pumped into the reaction kettle by the metering pump at the same time according to the mass ratio of 1:1.8:0.34:1, and the temperature is controlled at 35-40 Any value between ℃, react under normal pressure for 30 minutes, then extract the reactant, filter through a centrifuge to obtain the filtrate and ammonium chloride precipitate, and the ammonium chloride precipitate is dried in a dryer to obtain ammonium chloride.

[0020] Then, under the condition that the pressure is -0.098Mpa and the temperature is 100-120°C (any value between 100-120°C is feasible), the filtrate is distilled off 120# solvent gasoline through a falling film evaporator to obtain methyl tributyl ketone The crude product of oxime-based silane; continue to pass 120# solvent gasoline through the flash tank, and the distillate is cooled to obtain pure 120# solvent gasoline, and the remaining high boilers are returned to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com