Falling film evaporator with gas-liquid separating and membrane-distributing functions

A technology of falling film evaporator and gas-liquid separator, which is applied to evaporator accessories, horizontal tube evaporators, etc., can solve the problems of dryness, uneven distribution of refrigerant liquid, and restrictions on the application and promotion of horizontal tube falling film evaporators. Achieve the effect of improving heat exchange efficiency and avoiding uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The falling film evaporator with gas-liquid separation cloth membrane function of the present invention will be described in detail below with reference to the drawings and specific embodiments.

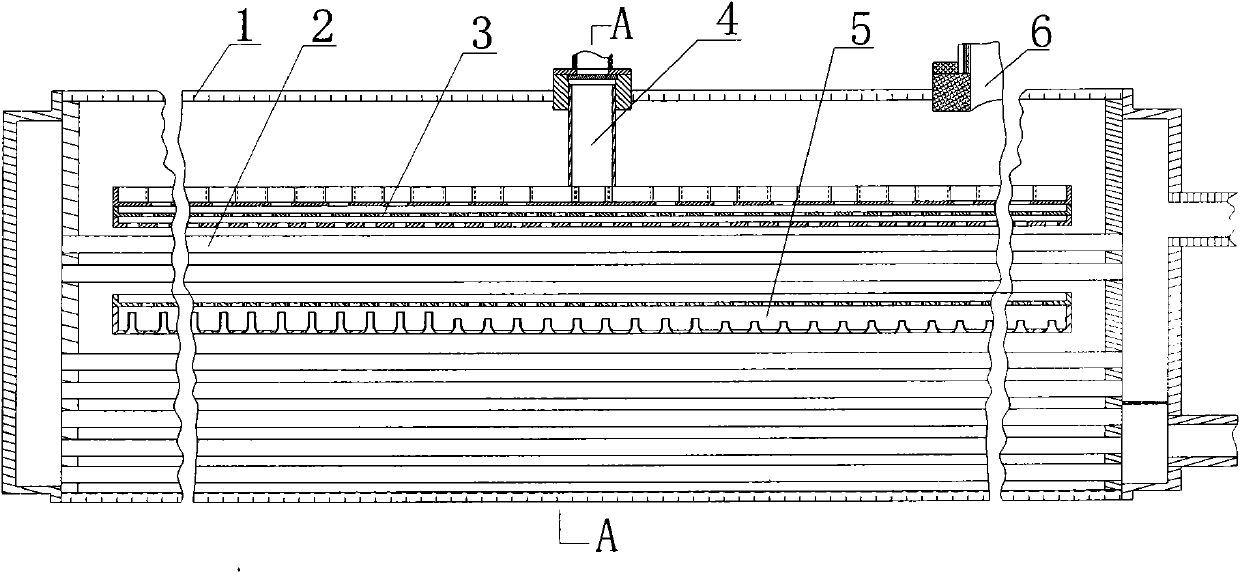

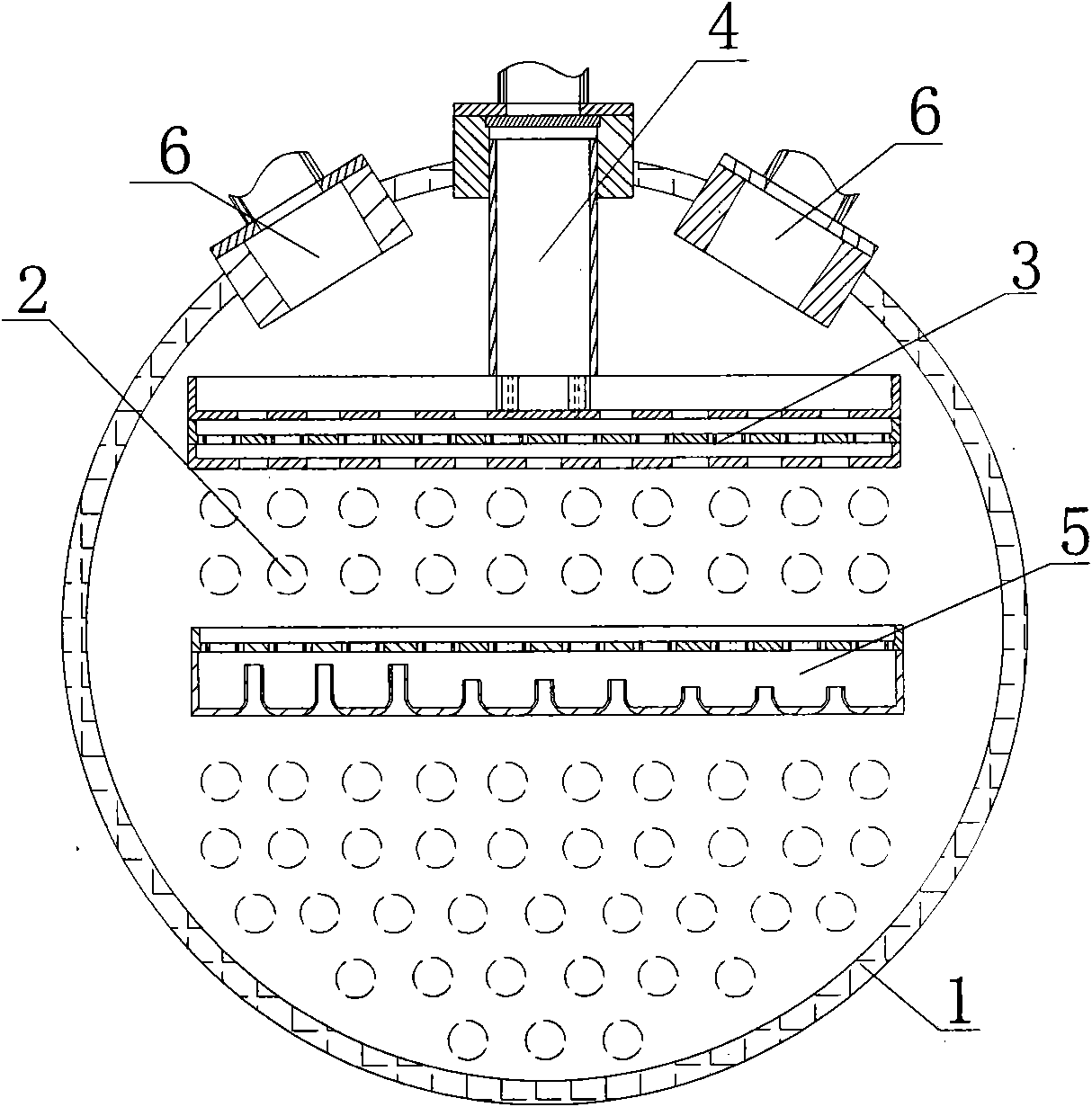

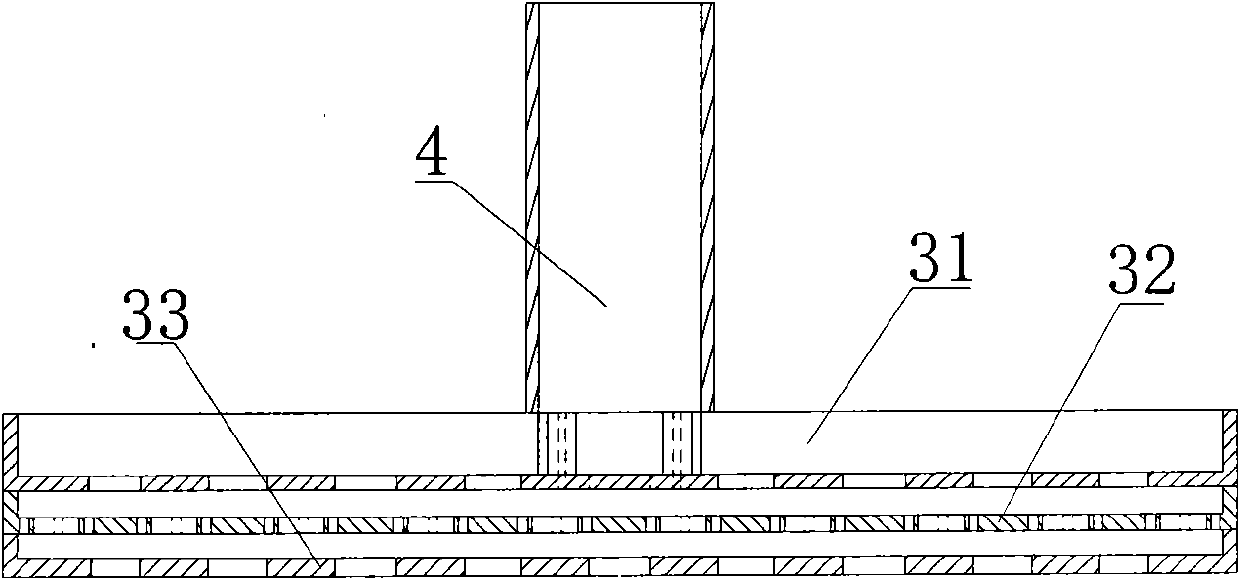

[0042] A falling film evaporator with gas-liquid separation cloth membrane function, such as figure 1 with figure 2 As shown, the evaporator shell 1 is provided with a number of heat exchange tubes 2, and also includes at least two layers of film distributors with gas-liquid separation function, the first layer of film distributors 3 and the refrigerant inlet pipe 4 of the evaporator In connection, the second layer of film distributor 5 is located below the first layer of film distributor 3, and at least one set of pipes 2 is provided between the second layer of film distributor 5 and the first layer of film distributor 3. The refrigerant is effectively separated from the refrigerant inlet pipe 4 in the first layer of membrane distributor 2 and effectively uniformly distributed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com