Method for removing and reclaiming sulfur dioxide from gas by low power consumption renewable absorbent

An absorbent and gas technology, applied in the field of removing and recovering sulfur dioxide, can solve problems such as loss of organic amines, large investment, and reduced absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

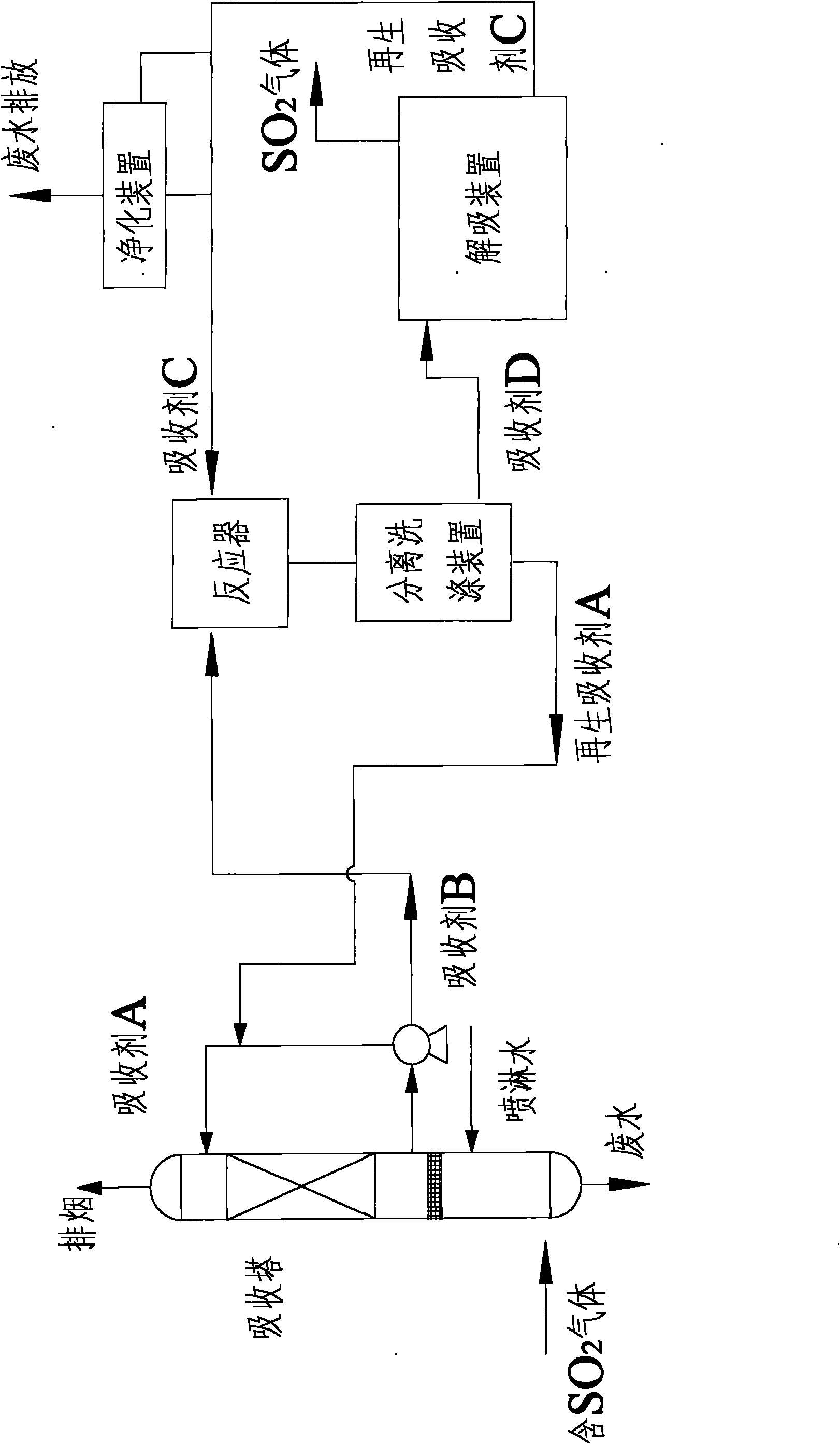

[0055] A certain 2Ot / h chain furnace boiler exhaust, SO 2 The content is 2000-5000ppm, and the temperature is 150°C. After a part of the flue gas is drawn from it into the absorption tower, it is first sprayed and washed to remove the dust and SO 3 and cool down, and then enter the absorption section, the SO in the flue gas 2 Absorbed by absorbent A, the gas is discharged from the top of the absorption tower to absorb SO 2 The final solution B has a pH value of 2.5-2.8, then enters the reactor, adds absorbent C to a pH value of 5.5-6.0, and the reaction temperature is 50°C, and then washes and separates to obtain a precipitate and solution D, and the precipitate is regenerated Absorbent A, the concentration of inorganic alkali and double salt in the original absorbent A and water are beaten by a slurry pump, and then enter the absorption tower for recycling, and the solution D is introduced into the desorption device, and SO is obtained by steam desorption. 2 Gas and regene...

Embodiment 2

[0061] As the conditions in Example 1, the difference is:

[0062] Absorbent A component: 10% by mass Mg(OH) 2 , 5% by mass of basic magnesium sulfite, 0.1% by mass of sulfur, and the rest being water;

[0063] The composition of absorbent C is: 80% by mass of tetraethylenepentamine, 0.2% by mass of magnesium thiosulfate, and the rest is water;

[0064] Its operating data is as follows:

[0065]

Embodiment 3

[0067] As the conditions in Example 1, the difference is:

[0068] Absorbent slurry A component: 15% by mass of Mg(OH) 2 , 5 mass% MgSO 3 , 0.15% by mass of p-phenylenediamine, the rest being water;

[0069] The composition of absorbent C is: 50% by mass of triethylenetetramine, 10% by mass of hydroxyethylethylenediamine, 0.1% by mass of sulfur, and the rest is water;

[0070] Its operating data is as follows:

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com