Brewing process of apple unblended wine and preparation method of apple unblended series wine

A technology of apples and raw wine, applied in the preparation of alcoholic beverages, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problem of difficult control of the quality stability of cider industrial products, increase the post-processing process of cider, and cause poor quality of cider Taste and other issues, to achieve the effects of reduced oxidation, accelerated fermentation speed, and increased alcohol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

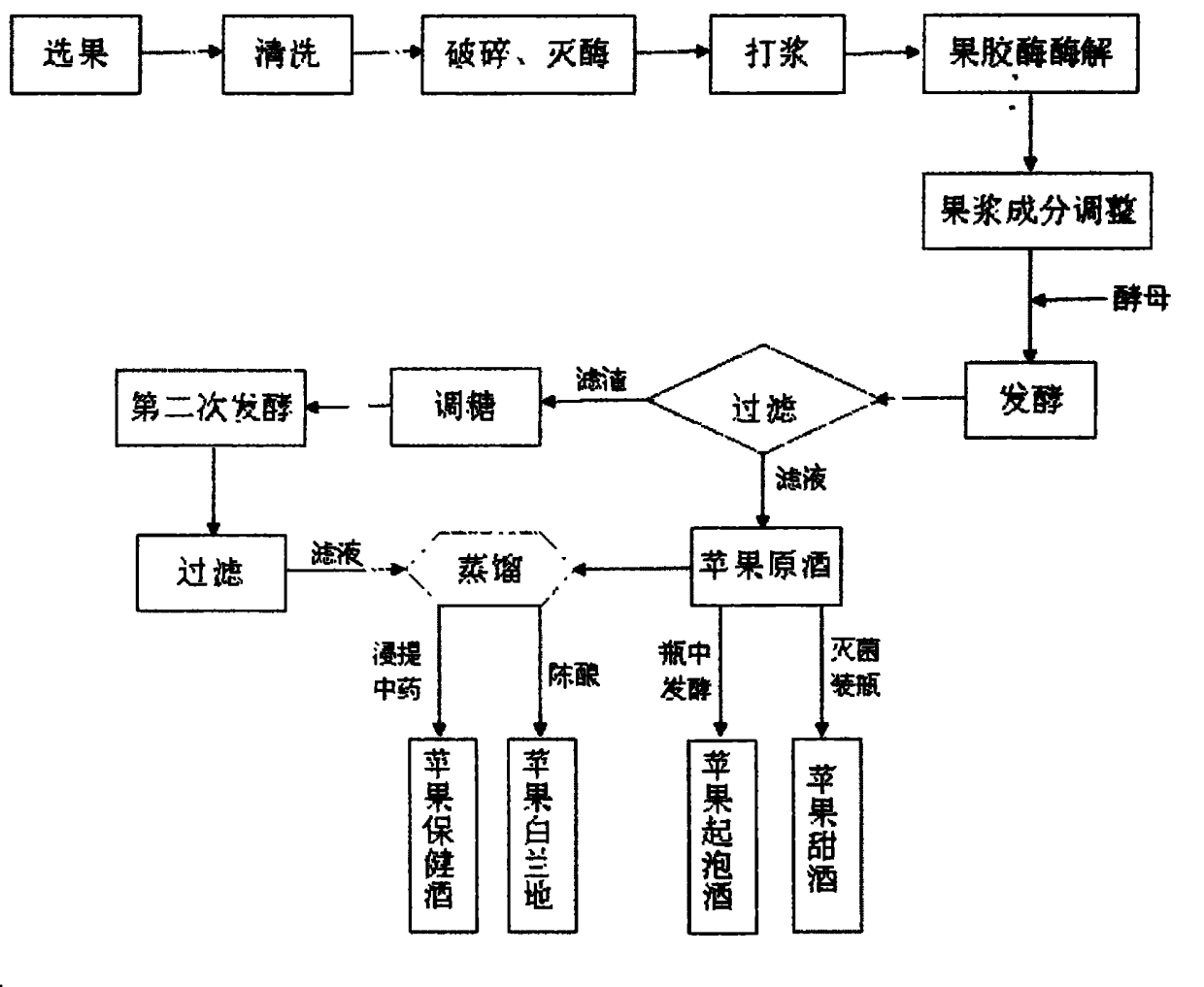

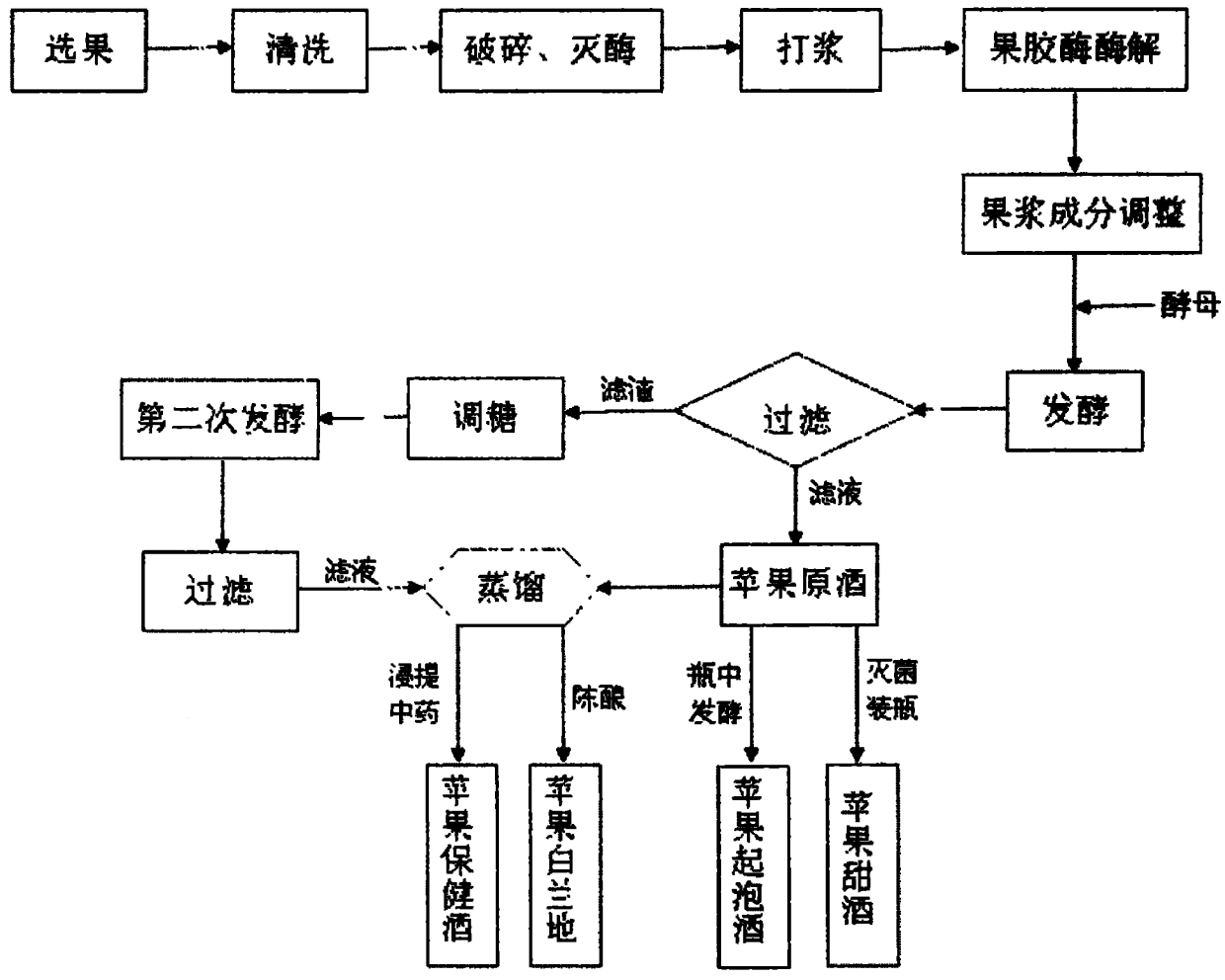

Method used

Image

Examples

Embodiment 1

[0026] Select crisp green apples with a juice acidity of 1.5-3.6 g / L and early-ripening red apples with a juice sugar content of 10-12 g / 100 ml and mix them in a ratio of 1:3 as raw materials for wine making. The raw materials were soaked in 1% sodium bicarbonate solution for 15 minutes, washed and drenched. Then crush the whole apple fruit and quickly put it into 100°C hot spring water with 30% of the raw material quality. After keeping it warm for 3 minutes, put it into a beater to make apple pulp with a particle size of 2-4mm. After stirring and cooling down, add the volume of fruit pulp to it. 0.05% liquid pectinase, stirring for 1 hour. The above process is the pre-treatment of raw material fermentation. After the pretreatment, measure the acidity and sugar content of the fruit pulp, adjust the sugar content of the fruit pulp to 22% and the acidity to 0.6g / L with fructose syrup with a sugar content > 70% and hot spring water, and add compound according to 0.1% of the pre...

Embodiment 2

[0028]Apple raw material and raw material fermentation pretreatment process are the same as implementation example 1. After the pretreatment, measure the acidity and sugar content of the pulp, and adjust the sugar content of the pulp to 12% and the acidity to 0.6g / L with fructose syrup with a sugar content>70% and hot spring water. The compound polypeptide is added according to 0.5% of the preadjusted pulp volume. After stirring evenly, when the temperature of the pulp drops below 35°C, add activated Saccharomyces cerevisiae in an amount of 2% of the volume of the pulp, and ferment for 7 days at 18°C-25°C to obtain the alcohol content (v / v) 6% and 4% Brix. After the fermentation is finished, the pomace in the fermentation broth is roughly filtered with double-layer gauze to obtain a crude filtrate, and then the yeast in the crude filtrate is removed by fine diatomaceous earth, and the 650nm light transmittance of the wine liquid is > 93%.

[0029] Mix the original wine with ...

Embodiment 3

[0031] Distilling the original cider in Example 2 can obtain distilled wine with a methanol content of <2g / L (100% ethanol) and an alcohol content (v / v) of 55%. Add 4g / L~6g / L oak chips to the wine, carry out continuous aging treatment at 60°C for 15 days, pour the barrel 3~6 times, and transfer the wine to oak barrels to continue aging for several years after cooling down. Carrying out alcohol content adjustment, color and luster adjustment rear bottling is the apple brandy of 40%~44% alcohol content (v / v) therebetween.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com