Nitrogen foam fracturing fluid for coal bed methane and preparation method of nitrogen foam fracturing fluid

A nitrogen foam and fracturing fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high friction resistance and no dispersion of pulverized coal, and achieve low filtration coefficient and small liquid filtration loss. , the effect of simple dispensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A coal bed gas nitrogen foam fracturing fluid, including gas phase and liquid phase, the gas phase is nitrogen, the liquid phase is an aqueous solution containing 0.45wt% foaming agent, 1.0wt% foam stabilizer, 0.20wt% gel breaker, gas phase and liquid phase The gas-liquid ratio of the phase is 3:1 volume ratio, which is produced by a foam generator; wherein: the foaming agent is made of sodium lauryl sulfate and N-(2-hydroxypropyl) perfluorooctylamide in a mass ratio of 8 : 1 composition system, the foam stabilizer is the viscoelastic surfactant cetyltrimethylammonium chloride, and the gel breaker is a redox system composed of ammonium persulfate and sodium sulfite in a mass ratio of 1:1.

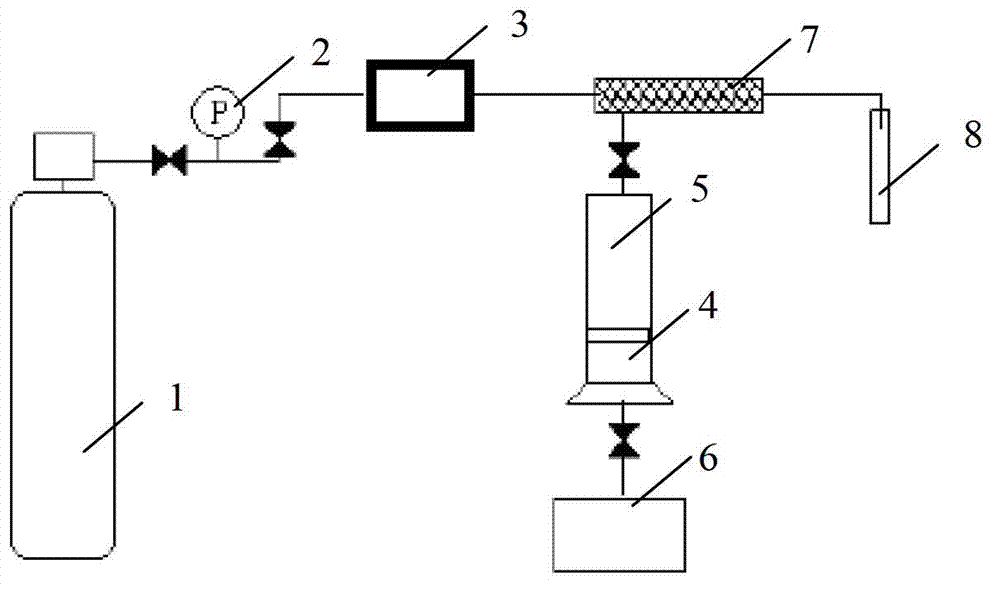

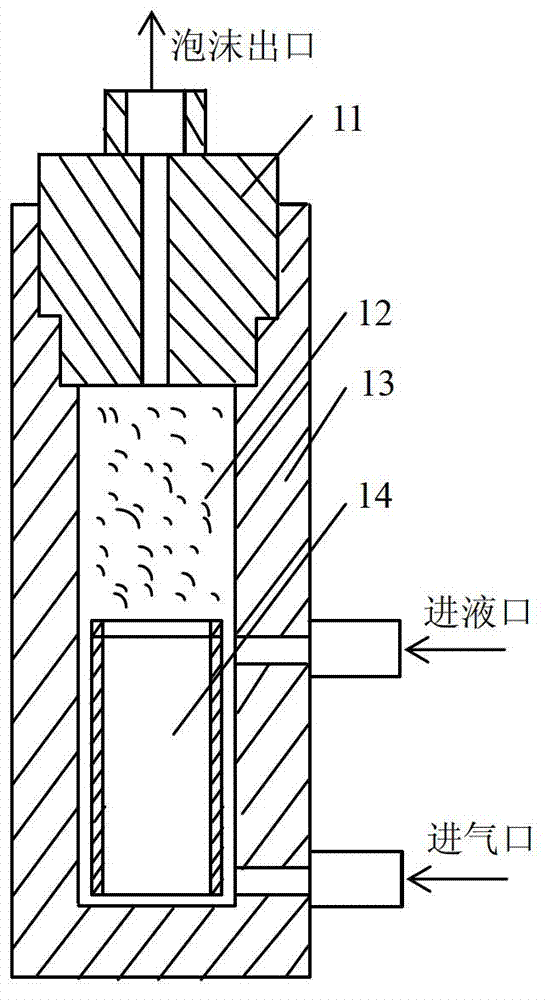

[0028] Preparation method: The schematic diagram of the preparation process is as follows figure 1 shown.

[0029] Formulated with 0.05% N-(2-hydroxypropyl) perfluorooctylamide (FCS-1), 0.4% sodium dodecyl sulfate (SDS), 1.0% cetyltrimethylammonium chloride (VES- A), 0.1%NH 4 S 2...

Embodiment 2

[0032] Formulated with 0.02% N-(2-hydroxypropyl) perfluorooctylamide, 0.2% sodium lauryl sulfate, 0.4% cetyltrimethylammonium chloride, 0.15% NH 4 S 2 o 8 and 0.15%Na 2 SO 3 Put the foaming liquid aqueous solution into the medicine container, inject the foam generator at a speed of 5ml / min through the pump, at the same time, release the nitrogen gas from the nitrogen cylinder, and inject the nitrogen gas at a speed of 10ml / min by setting the flow rate of the gas mass flow meter Foam generator; inject foaming liquid and nitrogen into the foam generator at the same injection speed at the same time, control the volume ratio of nitrogen and liquid to 2:1, that is, the foam quality is 67%, and obtain nitrogen foam fracturing fluid through the foam generator .

[0033] Put the above nitrogen foam fracturing fluid at 30°C, 1.5MPa, 170s -1 Under shearing for 30 minutes, the viscosity of the system basically remained at 53mPa·s. After 2 hours of gel breaking, the viscosity of the...

Embodiment 3

[0035] Preparation containing 0.02% FCS-1, 0.2% SDS, 0.4% octadecyltrimethylammonium chloride, 0.15% NH 4 S 2 o 8 and 0.15%Na 2 SO 3 The foaming liquid (liquid phase aqueous solution) is put into the medicine container, and injected into the foam generator through the pump at a speed of 5ml / min; at the same time, the nitrogen gas is released from the nitrogen gas bottle, and the nitrogen gas is injected into the foam generator by setting the flow rate of the gas mass flowmeter. Inject the foam generator at a speed of 20ml / min; inject the foaming liquid and nitrogen into the foam generator at the same time at their respective injection speeds, and control the volume ratio of nitrogen and liquid to 4:1, that is, the foam quality is 80%, obtained through the foam generator Nitrogen foam fracturing fluid.

[0036] Put the above nitrogen foam fracturing fluid at 30°C, 1.5MPa, 170s -1 Under shearing for 30 minutes, the viscosity of the system basically remained at 90mPa·s. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| System viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com