Bi-component polyurethane waterproof coating and preparation method thereof

A two-component polyurethane and waterproof coating technology, used in the field of waterproof coatings, can solve the problems of increased viscosity of flame retardants, inability to store and use for a long time, gelation, etc., and achieve the effects of long storage time, bright colors and good color retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a two-component polyurethane waterproof coating, including: A component, B component,

[0045] The raw material formula for preparing the A component includes: aliphatic isocyanate, flame-retardant polyether polyol;

[0046] The raw material formula for preparing the B component includes: a chain extender and a catalyst.

[0047] This embodiment provides a method for preparing the above-mentioned two-component polyurethane waterproof coating, and the following steps are carried out according to the above-mentioned formula:

[0048] Preparation of component A:

[0049] a. Heat up the flame-retardant polyether polyol to 100°C and dehydrate it for 5 hours under the condition of a vacuum of -0.01MPa;

[0050] b. Lower the temperature to 70°C, add aliphatic isocyanate, and react at 80°C for 2.5 hours to form a prepolymer of flame-retardant polyether polyol and aliphatic isocyanate, and discharge to obtain component A;

[0051] Preparation of compo...

Embodiment 2

[0056] This embodiment provides a two-component polyurethane waterproof coating, including: A component, B component,

[0057] The raw material formula for preparing described A component comprises:

[0058] 10 parts by weight of aliphatic isocyanate,

[0059] 100 parts by weight of flame-retardant polyether polyol;

[0060] The raw material formula for preparing the B component includes:

[0061] 20 parts by weight of chain extender,

[0062] Catalyst 0.2 parts by weight.

[0063] The aliphatic isocyanate is isophorone diisocyanate, the flame retardant polyether polyol is a halogenated polyether polyol, the molecular weight of the flame retardant polyether polyol is 500-5000, and the flame retardant The hydroxyl value of the type polyether polyol is 40-400mgKOH / g, the chain extender is an amine aliphatic chain extender, and the catalyst is stannous octoate and lead isooctanoate (mass ratio: 1:2).

[0064] This embodiment provides a method for preparing the above-mentione...

Embodiment 3

[0073] This embodiment provides a two-component polyurethane waterproof coating, including: A component, B component,

[0074] The raw material formula for preparing described A component comprises:

[0075] 25 parts by weight of aliphatic isocyanate,

[0076] 20 parts by weight of flame-retardant polyether polyol;

[0077] The raw material formula for preparing the B component includes:

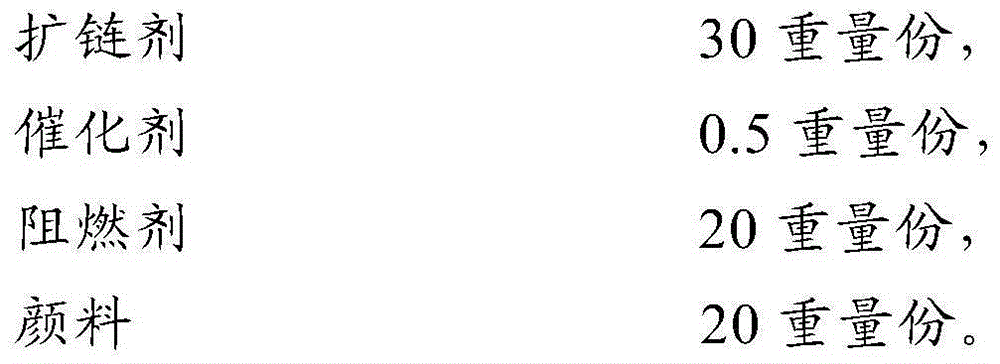

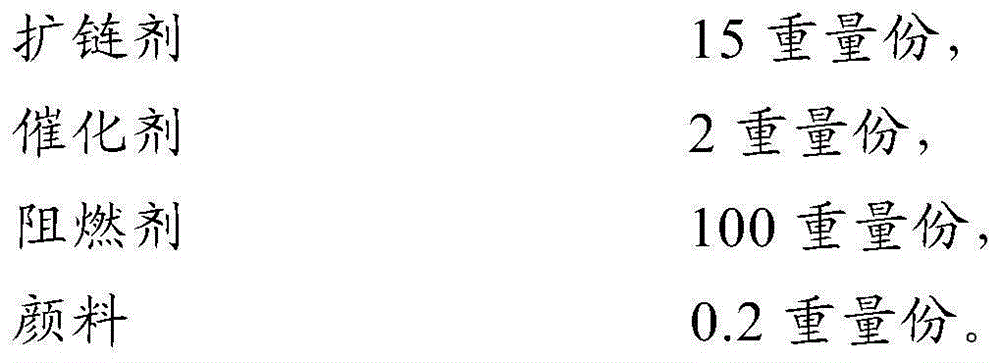

[0078]

[0079] The flame-retardant polyether polyol in the raw materials for preparing the A component in this embodiment has a flame-retardant effect, and at the same time, the flame-retardant polyether polyol can react with an aliphatic isocyanate to form a prepolymer. The prepolymer and the flame retardant in component B work together to prepare a highly flame-retardant two-component aliphatic polyurethane waterproof coating. The coating has excellent flame retardancy and weather resistance, bright colors, and good color retention. It is suitable for Direct waterproofing of exposed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com