Two component spray polyurea waterproof paint and preparation method and construction method of same

A waterproof coating, two-component technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of not being able to form a good appearance, and liquid materials cannot effectively wet and penetrate the substrate and other issues, to achieve the effect of good appearance, excellent aging resistance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

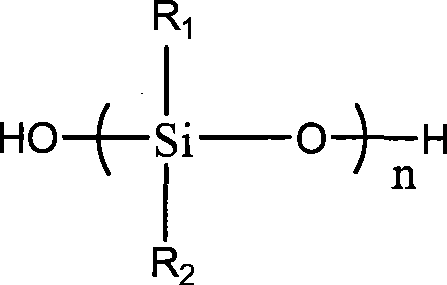

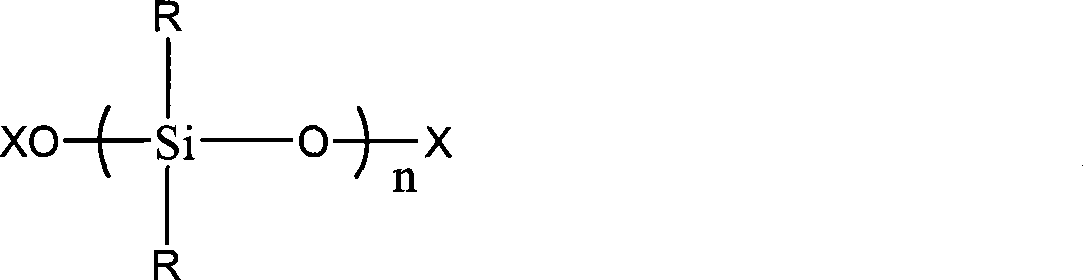

[0029] The two-component spray polyurea waterproof coating according to this embodiment includes A component and B component. The raw material system formula of component A is 55 parts (by weight) of isophorone diisocyanate, 35 parts of polypropylene glycol ether and 10 parts of hydroxyl-terminated polymethylsilane; the raw material system formula of component B includes 50 parts of amino-terminated polyether D-2000, 30 parts of amine chain extender Jeffling TM 754 and 20 parts of amino-terminated polymethylsilane.

[0030] The preparation method of above-mentioned waterproof coating is as follows:

[0031] (1) Preparation of component A: put 35 parts of polypropylene glycol ether (hydroxyl value 56KOHmg / g) and 10 parts of hydroxyl-terminated polymethylsilane into the reaction kettle and start stirring while raising the temperature to 110±5°C, vacuum pressure Dehydrate at -0.08MPa for 2h, then fill with nitrogen protection, cool down to 70°C, add 55 parts of isophorone dii...

Embodiment 2

[0035] The two-component spray polyurea waterproof coating according to this embodiment includes A component and B component. The raw material system formula of component A is: 45 parts of hexamethylene diisocyanate, 40 parts of polyethylene glycol ether and 15 parts of hydroxyl-terminated polymethylsilane; the raw material system formula of component B is 55 parts of amino-terminated polyether Jeffamine D-400, 35 parts amine chain extender Versalink TM 1000 and 20 parts of amino-terminated polymethylsilane.

[0036]The preparation method of above-mentioned waterproof coating is as follows:

[0037] (1) Preparation of component A: Put 40 parts of polyethylene glycol ether (hydroxyl value 56KOHmg / g) and 15 parts of hydroxyl-terminated polymethylsilane into the reactor and start stirring while heating up to 110±5°C. Dehydrate under vacuum pressure -0.08MPa for 2h. Fill with nitrogen protection, lower the temperature to 70°C, add 45 parts of hexamethylene diisocyanate, stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com