High-performance adsorption catalytic material and preparation method thereof

An adsorption catalysis, high-performance technology, applied in chemical instruments and methods, separation methods, molecular sieve catalysts, etc., can solve problems such as human health hazards, excessive volatile organic compound content, complex composition, source and toxicity, and achieve low cost , reduction of VOCs content reduction, and the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

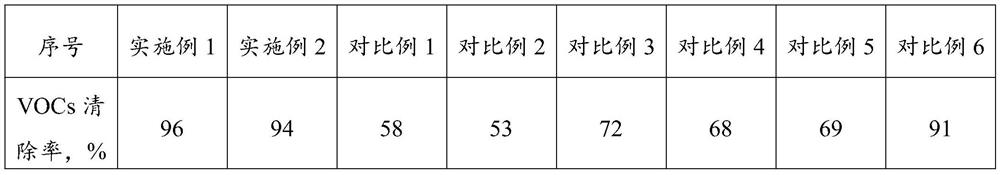

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of the high-performance adsorption catalytic material, comprising the following steps:

[0042] 1) Weigh raw materials in proportion;

[0043] 2) Put the active calcium silicate and zeolite into the high and low speed mixing tank, and stir at low speed until the material temperature is 90°C;

[0044] 3) Add modifier, deodorizing freshener, and coupling agent to the raw materials in step 2), and stir under high-speed conditions until the physical temperature is 110°C before releasing;

[0045] 4) Weigh and pack to obtain a high-performance adsorption catalyst material.

[0046] 6. The preparation method of high-performance adsorption catalytic material according to claim 2, characterized in that the low-speed condition in step 2) is 300-800r / min.

[0047] The preparation method of high-performance adsorption catalytic material according to claim 2, characterized in that the high-speed condition in step 2) is 1000...

Embodiment 1

[0050] A high-performance adsorption catalytic material is composed of the following raw materials in mass percentage:

[0051] Active Calcium Silicate 25%,

[0052] Zeolite 68%,

[0053] Modifier YH-A2%,

[0054] Modifier YH-B2%,

[0055] Deodorant Freshener 2.5%,

[0056] Coupling agent 0.5%.

[0057] The preparation method of the high-performance adsorption catalytic material comprises the following steps:

[0058] 1) Weigh raw materials in proportion;

[0059] 2) Put the active calcium silicate and zeolite into the high and low speed mixing tank, and stir to 90°C at a low speed of 600r / min;

[0060] 3) Add modifier, deodorant and freshener, and coupling agent to the raw materials in step 2), and stir at a high speed of 1500r / min to 110°C to release;

[0061] 4) Weigh and pack to obtain a high-performance adsorption catalyst material.

Embodiment 2

[0063] A high-performance adsorption catalytic material is composed of the following raw materials in mass percentage:

[0064] Active Calcium Silicate 20%,

[0065] Zeolite 70%,

[0066] Modifier YH-A2.5%,

[0067] Modifier YH-B2.5%,

[0068] Deodorant Freshener 4%,

[0069] Coupling agent 1%.

[0070] The preparation method of the high-performance adsorption catalytic material comprises the following steps:

[0071] 1) Weigh raw materials in proportion;

[0072] 2) Put the active calcium silicate and zeolite into a high-low speed mixing tank, and stir to 90°C at a low speed of 650r / min;

[0073] 3) Add modifier, deodorant and freshener, and coupling agent to the raw materials in step 2), and stir at a high speed of 1300r / min to 110°C to release;

[0074] 4) Weigh and pack to obtain a high-performance adsorption catalyst material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com