Carbon dioxide adsorbent, carbon dioxide adsorption tower and carbon dioxide recovery system

A carbon dioxide and adsorbent technology, applied in other chemical processes, chemical instruments and methods, gas treatment, etc., can solve the problems of poor adsorption capacity and unable to meet the needs of carbon dioxide recovery and utilization in the cement industry, and achieve strong adsorption capacity and promote harmony Good development and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In a preferred embodiment of the present invention, the preparation method of the above-mentioned carbon dioxide adsorbent comprises the following steps:

[0050] (a) subjecting alumina, silica, analcime, calcium zeolite, carbon molecular sieves and carbon nanotubes to plasma treatment;

[0051] (b) putting the plasma-treated alumina, silicon oxide, analcime, calcium zeolite, carbon molecular sieve and carbon nanotubes into the alkali metal compound solution for pre-soaking;

[0052] (c) Baking and drying the pre-soaked product so that the alkali metal compound is attached to the surface of alumina, silicon oxide, analcime, calcium zeolite, carbon molecular sieve and carbon nanotubes to obtain a carbon dioxide adsorbent precursor ;

[0053] (d) Calcining the precursor of the carbon dioxide adsorbent to obtain the carbon dioxide adsorbent.

[0054] In step (a), the surface area of aluminum oxide, silicon oxide, analcime, calcium zeolite, carbon molecular sieve and ca...

Embodiment 1

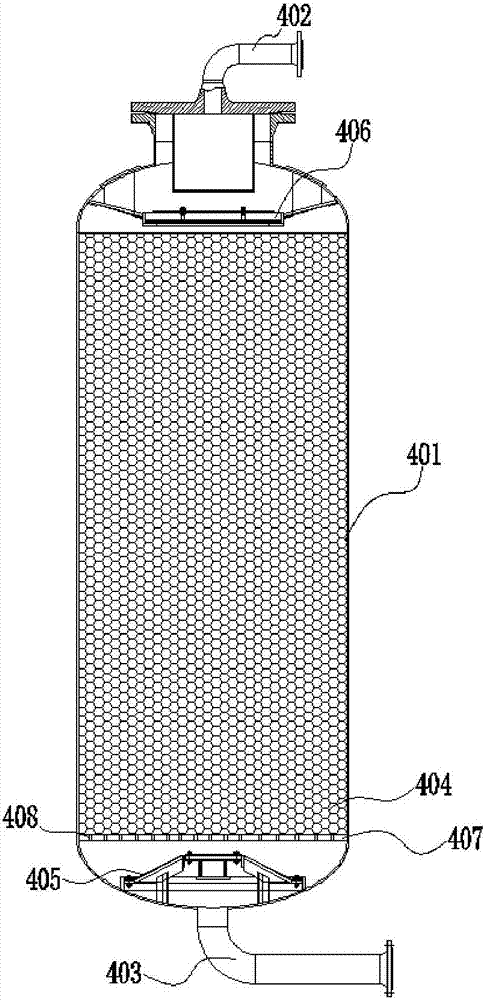

[0075] figure 1 For the carbon dioxide adsorption tower provided in this embodiment 1; as figure 1 As shown, the carbon dioxide adsorption tower provided in this embodiment includes a tower body 401, the top of the tower body 401 is provided with an exhaust port 402, the bottom of the tower body 401 is provided with an air inlet 403, and the bottom of the tower body 401 is provided with an air inlet port 403, the inside of the tower body 401 is provided with an air inlet 403, the inside of the tower body 401 is provided with a carbon dioxide adsorbent 404, the bottom of the tower body 401 is provided with a gas distributor 405, and the gas distributor 405 communicates with the air inlet 403, The top of the tower body 401 is also provided with a gas collector 406, the gas collector 406 is connected with the exhaust port 402, and the inside of the tower body 401 is also provided with a baffle plate 407 for supporting the carbon dioxide adsorbent 404, and the baffle plate 407 is ...

Embodiment 2

[0077] This embodiment provides a carbon dioxide adsorption tower. The difference between this embodiment and Embodiment 1 is that the carbon dioxide adsorbent filled in the carbon dioxide adsorption tower is mainly made of the following raw materials in parts by mass: 20 parts of alumina, 15 parts of silicon, 10 parts of analcite, 10 parts of calcium zeolite, 20 parts of carbon molecular sieve, 15 parts of carbon nanotube, 10 parts of alkali metal compound, the alkali metal compound is a mixture of lithium silicate, sodium sulfate and potassium aluminate, and three The molar ratio of the latter is 2:1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com