Novel aerogel reinforced nylon thermal insulation composite and preparation method thereof

A composite material and airgel technology, which is applied in the field of new airgel reinforced nylon thermal insulation composite materials and its preparation, can solve the problems of reducing the stability, strength and agglomeration of finished products, so as to improve compatibility, enhance fire resistance, The effect of enhancing the stability strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

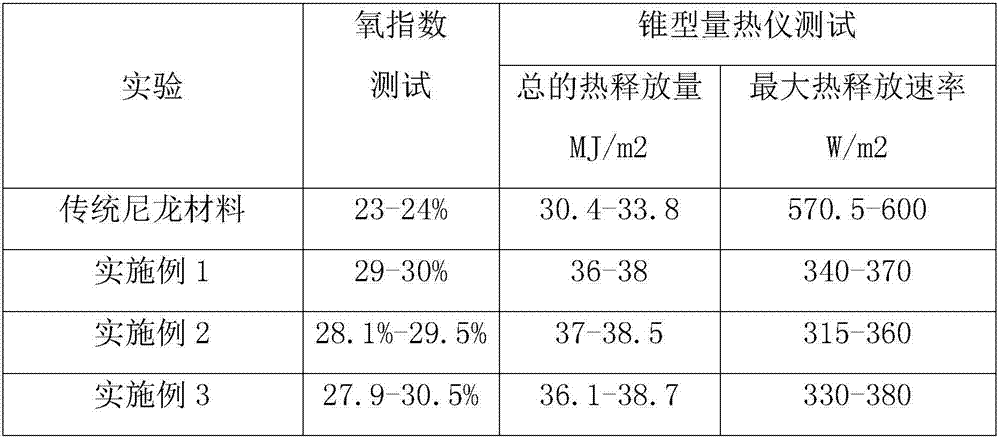

Examples

Embodiment 1

[0019] A novel airgel reinforced nylon thermal insulation composite material and a preparation method thereof, comprising the following steps:

[0020] (1) Get 3 parts by weight of 6-hydroxy-2-naphthoic acid, add it to 110 times its weight in deionized water, stir evenly, add 1 part by weight of zinc cyanurate, increase the temperature to 70 ° C, add 14 parts by weight Part of silica airgel, insulated and stirred for 50 minutes to obtain carboxylated gel solution;

[0021] (2) Get 5 parts by weight of benzyltriphenylphosphine chloride, add it to deionized water 20 times its weight, stir evenly, add 0.8 parts by weight of N,N-diethylaniline, and raise the temperature to 95 ℃, heat preservation and stirring for 20 minutes, add 0.1 parts by weight of anhydrous aluminum chloride, and stir to normal temperature to obtain a phosphine amine solution;

[0022] (3) Take 13 parts by weight of calcium zeolite, calcinate at 800° C. for 2 hours, cool to normal temperature, mix with 2 part...

Embodiment 2

[0028] A novel airgel reinforced nylon thermal insulation composite material and a preparation method thereof, comprising the following steps:

[0029] (1) Get 4 parts by weight of 6-hydroxy-2-naphthoic acid, add it to 140 times the weight of deionized water, stir evenly, add 1 part by weight of zinc cyanurate, increase the temperature to 75 ° C, add 14 parts by weight Part of silica airgel, insulated and stirred for 60 minutes to obtain carboxylated gel solution;

[0030] (2) Get 5 parts by weight of benzyltriphenylphosphine chloride, add it to deionized water 20 times its weight, stir evenly, add 2 parts by weight of N,N-diethylaniline, and raise the temperature to 95 ℃, heat preservation and stirring for 20 minutes, add 0.3 parts by weight of anhydrous aluminum chloride, and stir to normal temperature to obtain a phosphine amine solution;

[0031] (3) Get 13 parts by weight of calcium zeolite, calcinate at 800°C for 2 hours, cool to normal temperature, mix with 2 parts by ...

Embodiment 3

[0037] A novel airgel reinforced nylon thermal insulation composite material and a preparation method thereof, comprising the following steps:

[0038] (1) Get 3 parts by weight of 6-hydroxy-2-naphthoic acid, add it to 110 times its weight in deionized water, stir evenly, add 0.3 parts by weight of zinc cyanurate, increase the temperature to 70 ° C, add 14 parts by weight Part of silica airgel, insulated and stirred for 50 minutes to obtain carboxylated gel solution;

[0039](2) Get 4 parts by weight of benzyltriphenylphosphine chloride, add it to 17 times its weight in deionized water, stir evenly, add 0.8 parts by weight of N,N-diethylaniline, and raise the temperature to 90 ℃, heat preservation and stirring for 10 minutes, add 0.1 parts by weight of anhydrous aluminum chloride, and stir to normal temperature to obtain a phosphine amine solution;

[0040] (3) Take 10 parts by weight of calcium zeolite, calcinate at 700°C for 1 hour, cool to normal temperature, mix with 1 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com