Method for combined production of activative carbon, white carbon black and soda by employing biomass power plant waste

A technology for power plants and biomass, applied in chemical instruments and methods, silicon compounds, alkali metal compounds, etc., can solve problems such as increased energy consumption, waste of soda ash, pollution, etc., to reduce emissions, reduce carbon dioxide and sulfur-containing gases, The effect of increasing economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

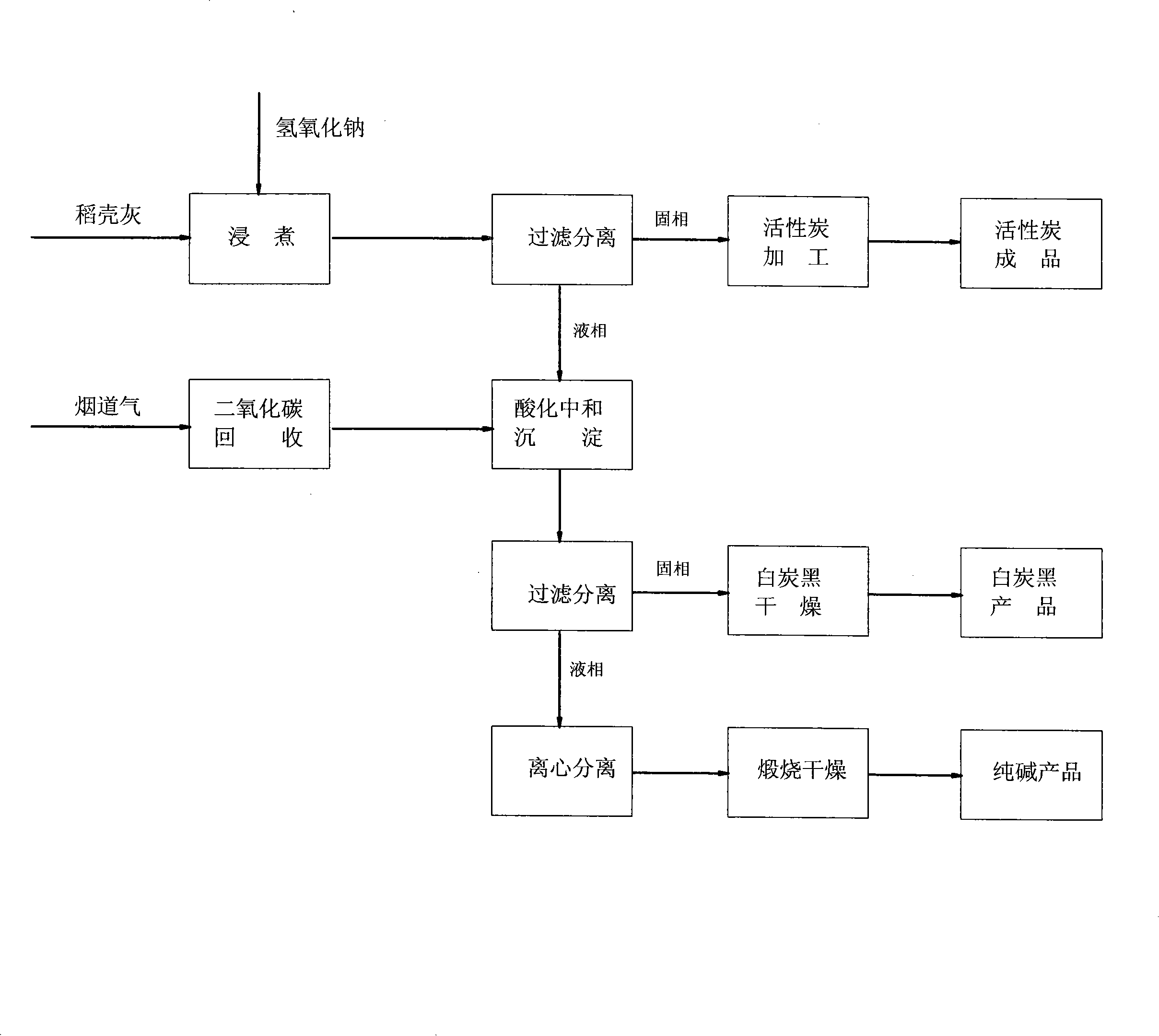

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0028] The technological process for co-producing activated carbon, white carbon black and soda ash by using waste from a biomass power plant shown in the accompanying drawing includes the following steps:

[0029] 1) Distilled rice husk ash: take rice husk ash with a carbon mass content of about 30% produced by burning rice husk in a biomass power plant as a raw material, and use a sodium hydroxide solution with a mass percentage concentration of 20 to 25% as a solvent. According to the volume ratio of sodium hydroxide solution and rice husk ash is 1: 2 ~ 2.5, mix them evenly, and then immerse them at 85 ~ 90 ℃ for 1.5 ~ 2.5h, so that the rice husk ash can be soaked in hydrogen A sufficient chemical reaction occurs in the sodium oxide solution to obtain a solid-liquid mixture of sodium silicate solution or sol and insoluble matter.

[0030] 2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com