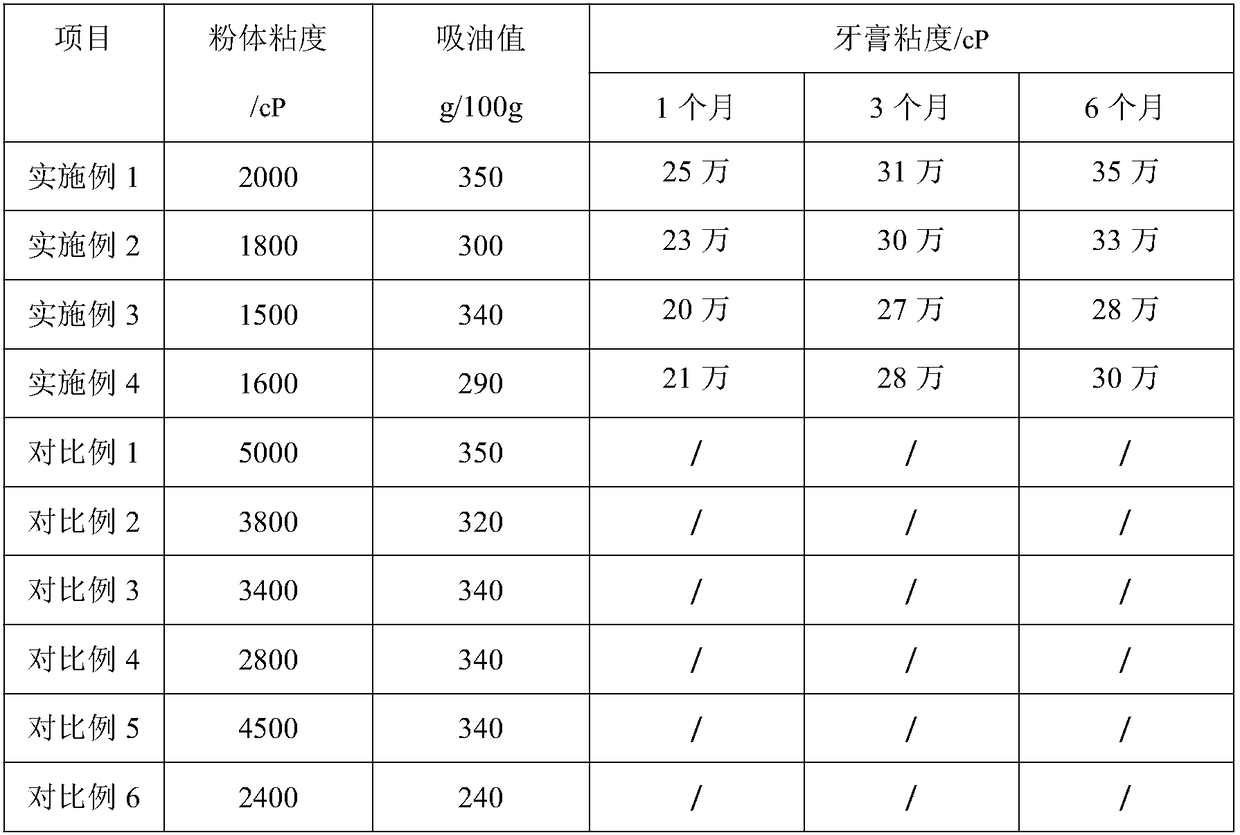

Preparation method of silicon dioxide of toothpaste with low viscosity and high oil absorption value

A silicon dioxide, high oil absorption technology, applied in chemical instruments and methods, cosmetic preparations, cosmetic preparations, etc., can solve the problems of toothpaste viscosity post-expansion, high powder viscosity, etc., to reduce viscosity and production cost. Low effect, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, the preparation method of silicon dioxide for toothpaste with low viscosity and high oil absorption value of the present invention

[0026] S1. After liquefying solid sodium silicate with a modulus of 2.5 at high temperature, add water to prepare a sodium silicate solution with a concentration of 3.5M, and set aside;

[0027] S2, add water 12m to the reactor 3 and sodium silicate solution 3m 3 , heated to 75°C, add sulfuric acid solution dropwise under stirring, control the dropwise addition time for 10 minutes, add dropwise until the pH is 9, stop adding acid, and stir for 10 minutes;

[0028] S3. Continue heating to 85°C, and add 8.5m sodium silicate solution dropwise while stirring. 3 and sulfuric acid solution, keep the pH of the process at 9, control the dropwise addition of the sodium silicate solution within 40 minutes, continue to drop the sulfuric acid solution until the pH of the reaction end point is 3.5, stop adding acid, age for 10 minutes, ...

Embodiment 2

[0032] Embodiment 2, the preparation method of silicon dioxide for toothpaste with low viscosity and high oil absorption value of the present invention

[0033] S1. After liquefying the solid sodium silicate with a modulus of 2.8 at high temperature, add water to prepare a sodium silicate solution with a concentration of 4.5M, and set aside;

[0034] S2, add water 14m in the reactor 3 and sodium silicate solution 3m 3 , heated to 80°C, add sulfuric acid solution dropwise under stirring, control the dropping time for 30min, dropwise add until the pH is 10, stop adding acid, and stir for 10min;

[0035] S3. Continue heating to 85°C, and add 10m sodium silicate solution dropwise while stirring. 3 and sulfuric acid solution, keep the pH of the process at 10, control the dropwise addition of the sodium silicate solution within 60min, continue to dropwise add the sulfuric acid solution until the pH of the reaction end point is 4.0, stop adding acid, age for 30min, press filter, an...

Embodiment 3

[0039] Embodiment 3, the preparation method of silicon dioxide for toothpaste with low viscosity and high oil absorption value of the present invention

[0040] S1. After liquefying the solid sodium silicate with a modulus of 2.6 at high temperature, add water to prepare a sodium silicate solution with a concentration of 4.0M, and set aside;

[0041] S2, add water 13m in the reactor3 and sodium silicate solution 3m 3 , heated to 75°C, add sulfuric acid solution dropwise under stirring, control the dropwise adding time to 20min, dropwise add until the pH is 10, stop adding acid, and stir for 10min;

[0042] S3. Continue heating to 85°C, and add 9m sodium silicate solution dropwise while stirring. 3 and sulfuric acid solution, keep the pH of the process at 9, control the dropwise addition of the sodium silicate solution within 50 minutes, continue to drop the sulfuric acid solution until the pH of the reaction end point is 3.5, stop adding acid, age for 20 minutes, press filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oil absorption value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com