High water dispersity titanium dioxide and coating method thereof

A titanium dioxide and dispersive technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of unreachable, high coating volume, poor dispersion performance, etc., and achieve reduced production costs and simple steps , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0024] Experimental Example 1 Al 2 o 3 with SiO 2 Determination of the amount of coating

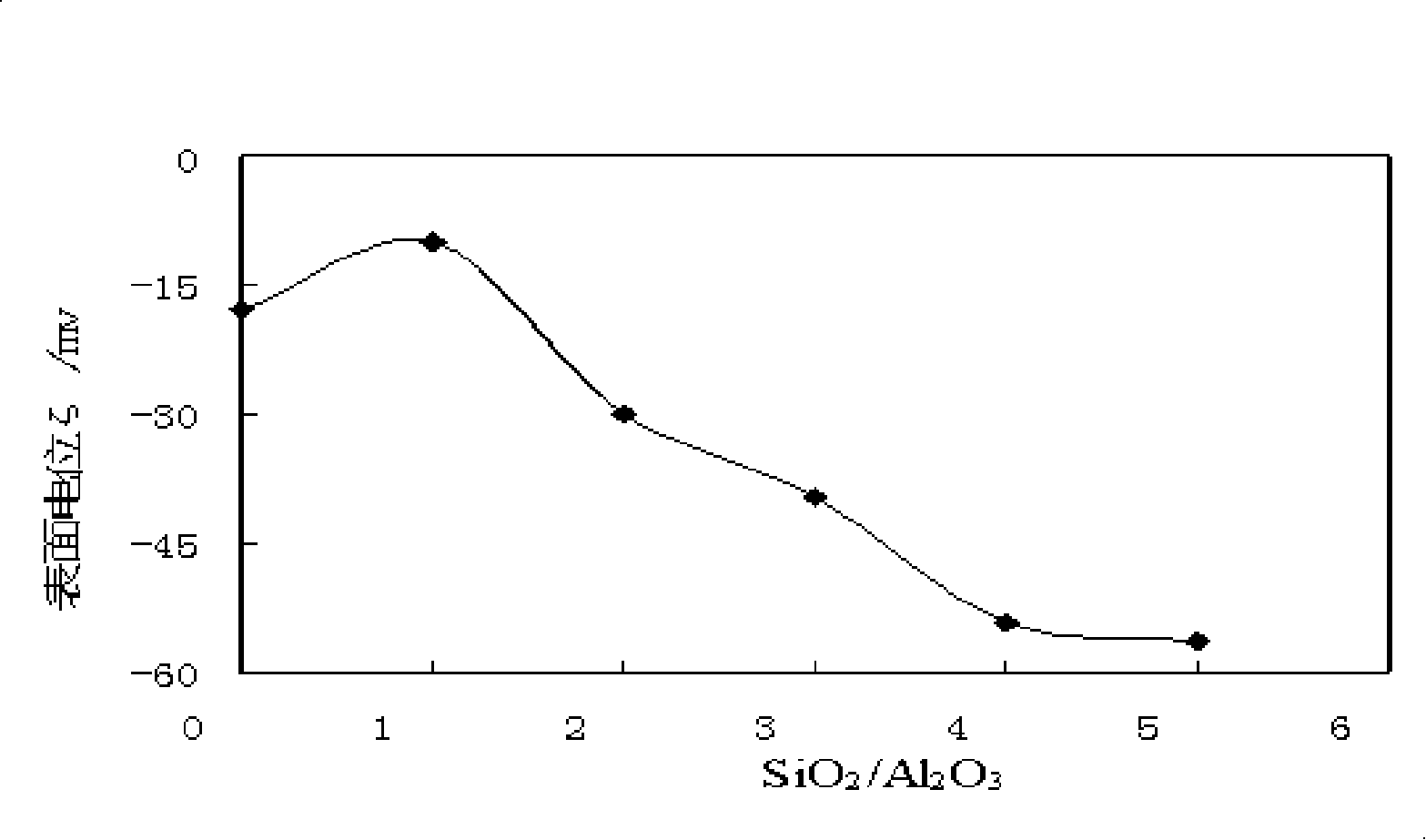

[0025] According to data reports (Tang Zhenyu. Titanium dioxide production and environmental governance [M]. Chemical Industry Press, 2000, 1: 189-190) SiO 2 / Al 2 o 3 When the molar ratio is greater than 1 (the following are all molar ratios), it is beneficial for TiO 2 Water dispersibility, so the experiment studied SiO under the conditions of suitable coating temperature, suitable coating pH value and co-current neutralization mode. 2 / Al 2 o 3 The dispersibility at 0, 1:1, 2:1, 3:1, 4:1 and 5:1 is reflected by the size of the surface potential.

[0026] Test conditions: coating temperature 90°C, coating pH: silicon-coated 10.6-12.0, aluminum-coated 9.4-10.6, sodium silicate concentration 80-120g / l, sulfuric acid concentration 10%-15%, sodium aluminate The concentration is 80~120g / l.

[0027] Test results: iffigure 1 shown.

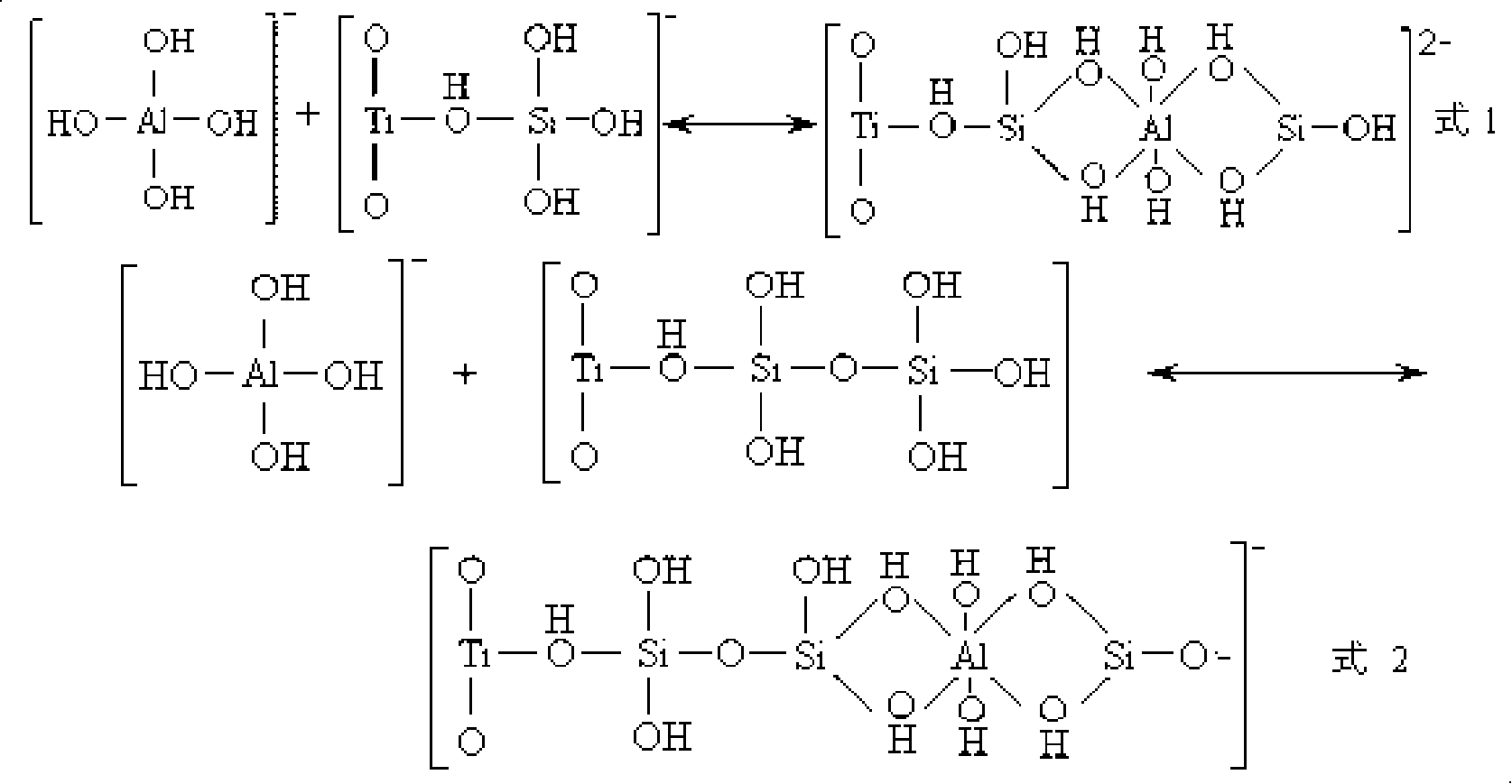

[0028] From figure 1 It can be seen that with S...

Embodiment 1

[0035] Embodiment 1 Preparation of highly water-dispersible titanium dioxide

[0036] 1200g of the primary product of titanium dioxide is beaten with deionized water to form a TiO-containing 2 To make a 200g / l slurry, add 4.8g of sodium hexametaphosphate, and at the same time use 10% to 15% NaOH solution to adjust the pH of the system to 9.0. Sand the slurry to 325 mesh and dilute to TiO with deionized water 2 120g / l. Take 120g / l TiO 2 Slurry 5000ml (containing TiO 2 600 g), heated to 90°C, and adjusted the pH of the system to 10.6 with 10% to 15% NaOH at the same time, kept the temperature for 10 minutes and detected the pH of the system. Add 180ml of 100g / l sodium silicate solution to the system at a constant speed within 150min, and at the same time add 20% dilute sulfuric acid dropwise to the system to ensure that the pH of the system is 10.6, and ripen for 30min after the addition. Use 10% dilute sulfuric acid to adjust the pH of the system to 9.0, keep it warm for 1...

Embodiment 2

[0038] Example 2 Preparation of highly water-dispersible titanium dioxide

[0039] 1200g rutile nano-TiO 2 Beating with deionized water into TiO-containing 2 To make a slurry of 180g / l, add 3.6g of sodium hexametaphosphate, and at the same time use 10% to 15% NaOH solution to adjust the pH of the system to 9.5. Sand the slurry to 325 mesh and dilute to TiO with deionized water 2 100g / l. Take 100g / l TiO 2 Slurry 6000ml (containing TiO 2 600 g), heated to 90°C, and adjusted the pH of the system to 11.2 with 10% to 15% NaOH at the same time, kept the temperature for 10 minutes and detected the pH of the system. Add 300ml of 80g / l sodium silicate solution to the system at a constant speed within 180min, and at the same time add 20% dilute sulfuric acid dropwise to the system to ensure that the pH of the system is 11.2, and ripen for 30min after the addition. Use 10% dilute sulfuric acid to adjust the pH of the system to 9.8, keep it warm for 10 minutes and check the pH of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com